- 1. Overview of the Global Steel Pipe Market

- 2. Steel Pipe Market Demand Analysis

- 3. Steel Pipe Market Supply Analysis

- 4. Imbalance of Supply and Demand in the Steel Pipe Market and Its Impacts

- 5. Future Trends and Outlook of the Steel Pipe Market

- 6. How to Respond to Supply and Demand Fluctuations in the Steel Pipe Market

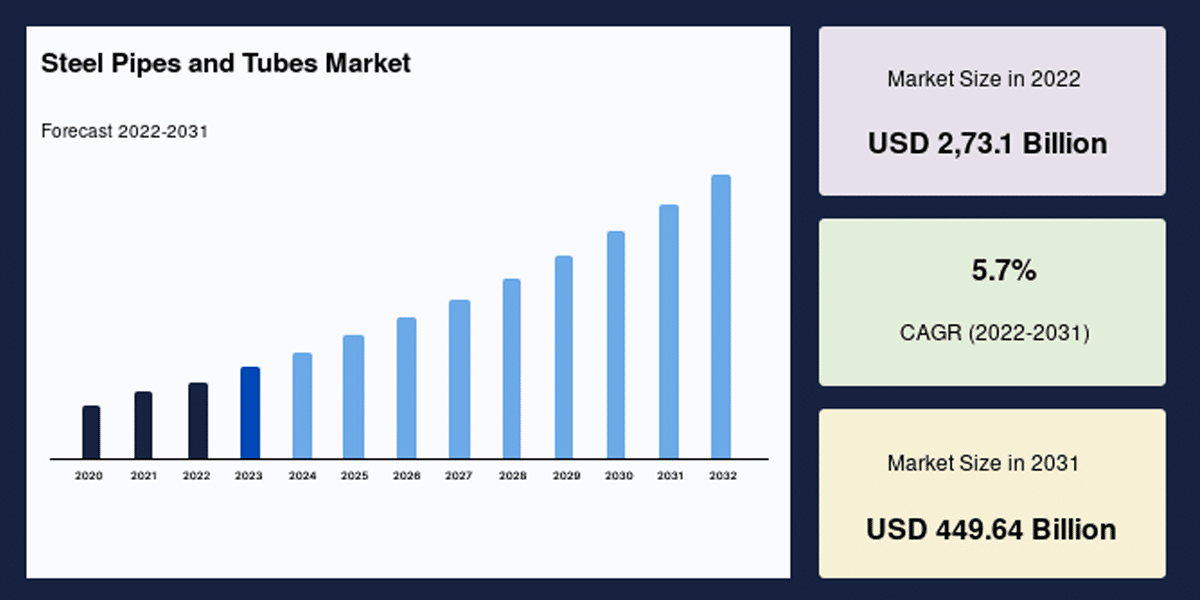

In the current global economic environment, the steel pipe market is facing numerous challenges and opportunities in terms of supply and demand. As infrastructure projects continue to advance and the demand from industries such as oil and gas, construction, and water treatment grows, the demand for steel pipes has been steadily increasing. However, the supply chain for steel pipes is also facing multiple challenges, including raw material shortages, rising production costs, and logistical difficulties.

These factors have not only impacted steel pipe production and delivery but have also led to price fluctuations and market uncertainty. This article will provide an in-depth analysis of the current supply and demand situation in the steel pipe market, exploring the demand trends in the global steel pipe market and the pressures faced by the supply side. Through a comprehensive analysis of steel pipe demand and supply, we will present the core dynamics of the market and provide insights into its future trajectory!

Overview of the Global Steel Pipe Market

The global steel pipe market is a key segment of the global steel industry, widely used across various sectors such as construction, energy, transportation, and water treatment. The demand for steel pipes continues to grow as countries invest in economic development and infrastructure projects. By analyzing the market distribution, types of steel pipes, and industry demand, we can gain a better understanding of the current situation and development trends in the global steel pipe market.

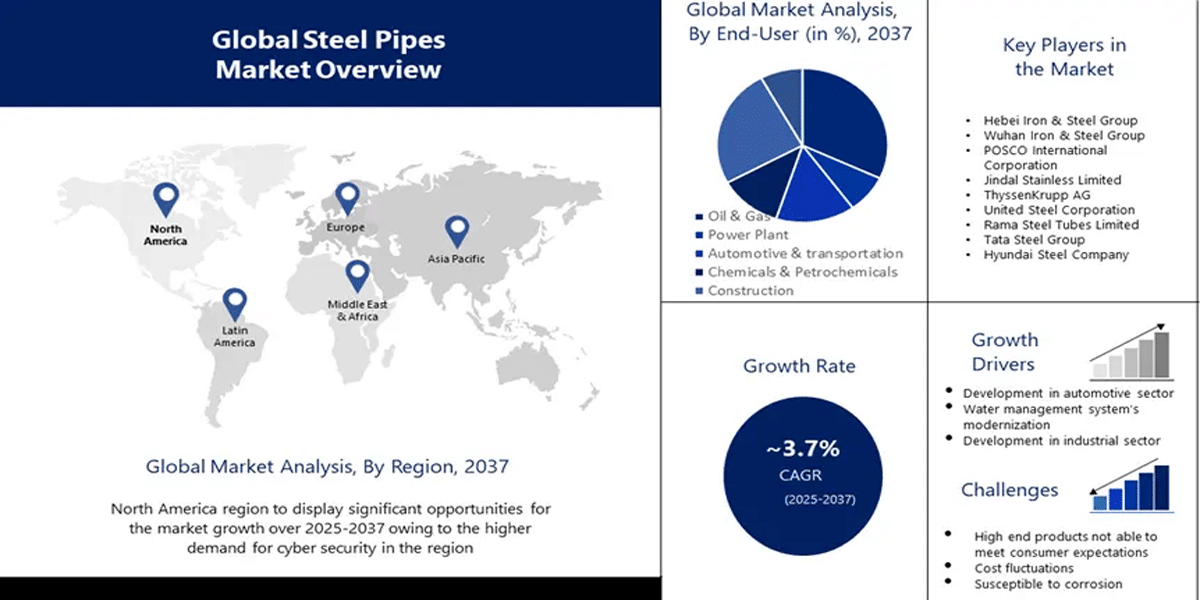

Steel Pipe Market Distribution

The demand for steel pipes varies significantly by region. While developed countries and regions like North America and Europe remain the primary markets for steel pipes, the demand is gradually shifting towards emerging markets in Asia, Africa, and Latin America due to their rapid growth.

North American Market: The United States and Canada are major consumers of steel pipes in North America. With the advancement of shale oil and gas extraction technologies, demand remains strong. Additionally, the construction and infrastructure sectors are significant contributors to steel pipe demand.

European Market: The European steel pipe market is focused on the energy, automotive, and construction industries. The growing investments in green energy are driving the demand for steel pipes in energy pipeline projects.

Asia-Pacific Region: China, India, and Southeast Asian countries are the largest consumers of steel pipes in the Asia-Pacific region. China, as the world’s largest producer and consumer of steel pipes, primarily drives demand from infrastructure development and the oil and gas industry. Additionally, industrialization in India and Southeast Asia also boosts the steel pipe market.

Middle East and Africa: With increasing oil and gas exploration activities and expanding infrastructure projects, the demand for steel pipes in the Middle East and Africa is steadily rising.

Steel Pipe Types

Steel pipes can be categorized based on manufacturing processes, usage, and materials. The most common types include:

Seamless Steel Pipe: Seamless steel pipes are widely used in high-pressure, high-temperature environments such as oil and gas transportation, chemical industries, boilers, and high-pressure pipelines. Their lack of seams gives them better mechanical properties and corrosion resistance.

Welded Steel Pipe: Welded steel pipes are primarily used for fluid transportation in low-pressure environments, such as water, gas, and oil pipelines. They are cost-effective and suitable for mass production and long-distance transportation.

Spiral Welded Steel Pipe: These pipes are commonly used in the oil, gas, and water pipeline industries due to their simple manufacturing process and low cost.

Coated Steel Pipe: Coated steel pipes have a protective coating applied to their surface (such as epoxy resin, zinc, polyethylene, etc.), which significantly improves their corrosion resistance, wear resistance, and chemical resistance. They are widely used in oil and gas pipelines, water treatment pipelines, and construction pipelines.

Alloy Pipe: Alloy pipes are steel pipes made from alloy steel that contains various alloying elements (such as chromium, nickel, molybdenum, vanadium, etc.). These pipes offer superior high-temperature, high-pressure, and corrosion-resistant properties. Alloy pipes are commonly used in the oil and gas industry, chemical equipment, and boiler pipelines, especially in environments that require high strength, corrosion resistance, and high-temperature tolerance.

Square and Rectangular Tubes: These pipes are used in structural applications such as buildings, steel structures, and machinery manufacturing, where they are exposed to significant pressure and mechanical stress.

Steel Pipe Market Demand Analysis

Steel pipe demand is primarily influenced by the following factors:

Energy Industry: The extraction and transportation of oil and natural gas are major drivers of steel pipe demand. As global energy demand rises, particularly in oil and gas exploration, steel pipes play a crucial role in pipeline construction.

Infrastructure Development: With increased government investments in infrastructure, the demand for steel pipes continues to grow. Particularly in the water treatment, transportation, and construction industries, steel pipes are widely used in water supply pipelines, railways, bridges, and more.

Manufacturing and Industrialization: The growth of global manufacturing industries has driven the demand for steel pipes. Particularly in construction, machinery, and automotive industries, the need for steel pipes has been steadily increasing.

Steel Pipe Supply Chain Challenges: The steel pipe industry faces several challenges, including fluctuations in raw material prices, production overcapacity, and logistics issues. Specifically, global supply chain disruptions have affected the prices of raw materials like steel, leading to increased production costs and impacting supply-demand balance. Additionally, stricter environmental regulations are forcing manufacturers to adopt more environmentally friendly production methods, which may further increase production costs.

Steel Pipe Market Demand Analysis

With the continuous advancement of global infrastructure development and industrialization, the demand for steel pipes has been steadily increasing. Due to their excellent strength, corrosion resistance, and broad applicability, steel pipes have become an essential material across numerous industries. Currently, the major sources of demand for steel pipes can be summarized as follows:

Strong Demand from the Energy Sector: Oil and gas exploration and transportation remain the most critical applications for steel pipes. Both onshore and offshore projects require high-strength, high-pressure-resistant, and corrosion-resistant pipes. In particular, API 5L standard pipes and alloy pipes are widely used in this sector.

Infrastructure Construction Drives Market Growth: Globally, especially in developing countries, rapid urbanization is fueling large-scale construction of water supply, drainage, gas distribution, and transportation networks. This has led to a sharp increase in demand for municipal pipes, construction-grade steel pipes, and structural steel pipes. Coated steel pipes are also widely adopted for their superior anti-corrosion properties.

Consistent Demand from Industrial Manufacturing: Steel pipes are extensively used in machinery, automotive, shipbuilding, boiler production, and other manufacturing industries. As global manufacturing recovers and undergoes upgrades, the demand for various specifications and performance-grade steel pipes continues to grow.

Shifting Global Demand Structure: Regionally, the Asia-Pacific market—particularly China, India, and Southeast Asia—has become the core of global steel pipe consumption, driven by dense infrastructure projects and accelerated energy development. Meanwhile, regions such as the Middle East and Africa are seeing steady growth in steel pipe demand due to increased energy investments.

Policy and Green Transition Effects: Many governments are promoting strategies like green energy and carbon neutrality, which in turn stimulate new rounds of demand for specialized steel pipes—such as high-performance alloy pipes and corrosion-resistant coated pipes—used in wind power, solar energy, and other emerging energy sectors.

Steel Pipe Market Supply Analysis

Amid rising global demand, the supply capacity of the steel pipe market has also expanded steadily. However, steel pipe supply is influenced not only by production capacity but also by factors such as raw material costs, energy prices, environmental policies, trade restrictions, and the stability of global supply chains. The current characteristics and challenges of steel pipe supply can be summarized as follows:

Significant Regional Disparities in Global Production Capacity: The major steel pipe-producing countries include China, India, the United States, Japan, and Germany. China is the world’s largest steel pipe producer, with a complete industrial chain and strong capacity coordination. India and Southeast Asian countries are emerging as new supply bases, taking on transferred mid- to low-end capacity.

Raw Material Price Volatility Affects Production Output: Steel pipes are made primarily from steel, so fluctuations in steel prices directly affect production costs and the willingness of suppliers to produce. Increases in the prices of raw materials such as iron ore, coke, and scrap steel can significantly raise manufacturing costs, especially for small and mid-sized producers.

Energy and Environmental Policies Constrain Capacity Expansion: In recent years, many countries have tightened environmental regulations. For example, China’s “carbon peaking and carbon neutrality” policies have imposed stricter controls on energy consumption and emissions in the steel industry, leading to capacity reductions or technical upgrades, which limit short-term production flexibility.

Supply Chain Stability Remains Challenging: The steel pipe supply chain involves international raw material procurement, cross-border logistics, and distribution. Disruptions caused by geopolitical tensions, recurring pandemics, or port congestion continue to impact the timely delivery of certain types of steel pipes—especially high-specification pipes used in critical infrastructure projects.

Technology and Product Structure Influence Supply Efficiency: The production of specialized pipes—such as coated pipes, alloy pipes, and high-pressure boiler tubes—requires advanced equipment, technical expertise, and strict quality control. Some countries, while having basic production capacity, still rely on imports or a limited number of large enterprises to meet demand for high-end pipe types.

Imbalance of Supply and Demand in the Steel Pipe Market and Its Impacts

In recent years, influenced by uneven global economic recovery, geopolitical tensions, fluctuating energy prices, and tightening environmental policies, the steel pipe market has experienced periodic imbalances between supply and demand. This mismatch has not only led to significant price volatility but also brought long-term operational impacts on both upstream and downstream players in the industry. The main effects include:

Sharp Price Fluctuations Triggered by Supply-Demand Mismatch: In certain regions, demand for steel pipes surges rapidly—particularly during the launch of large-scale energy or infrastructure projects—while supply is constrained by environmental regulations, logistics disruptions, or raw material shortages. This causes prices to spike, especially for high-spec pipes like API 5L or alloy pipes. Conversely, when demand weakens or projects are delayed, high inventories push prices down sharply, creating roller-coaster-like volatility.

Increased Risk for Project Implementation: Steel pipes are essential for infrastructure and energy construction. Price uncertainty and delayed delivery schedules can lead to cost overruns or project delays. For large-scale international projects, disruptions in steel pipe supply may jeopardize the entire timeline and budget planning.

Pressure on Small and Medium Enterprises (SMEs): While large manufacturers may secure stable orders and raw material sources, SMEs are more vulnerable during periods of supply chain stress. Rising material and transport costs shrink profit margins and may even force temporary shutdowns.

Enterprises Adjusting Procurement and Supply Chain Strategies: To mitigate risks from supply-demand instability, buyers are increasingly favoring long-term contracts, diversified supplier networks, or partnerships with manufacturers known for stable delivery. Some major companies are also investing upstream in steel resources or coated pipe production lines to strengthen supply chain control.

Driving Industry Upgrading and Transformation: The supply-demand imbalance is pushing steel pipe manufacturers to shift toward higher-value, performance-oriented products. This includes investing in smart manufacturing and green production lines to boost resilience. Products like alloy pipes and coated steel pipes are seeing increased demand and are helping manufacturers differentiate themselves in a competitive market.

Future Trends and Outlook of the Steel Pipe Market

With global economic restructuring, the transformation of the energy sector, and continued investment in infrastructure, the steel pipe market is expected to remain vibrant in the coming years. However, it will also face challenges related to technology, cost, and sustainability. The future development of the steel pipe industry is likely to follow these key trends:

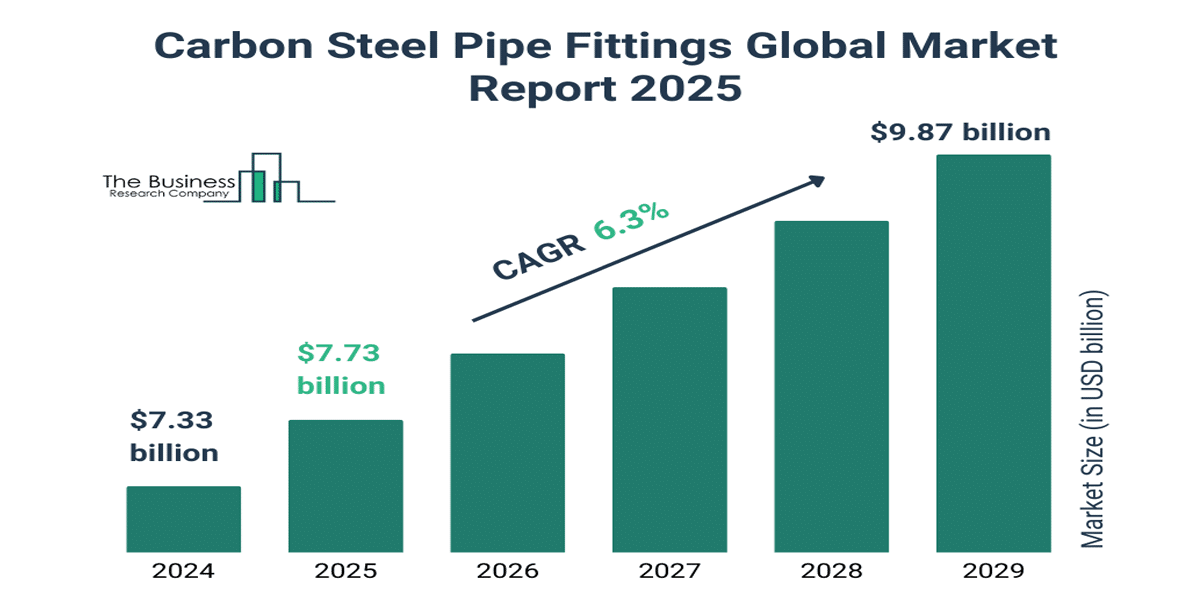

High-Performance and High Value-Added Products Becoming Mainstream: As competition intensifies for conventional steel pipes, profit margins are narrowing. Manufacturers are shifting toward high-performance products with superior strength, corrosion resistance, and heat resistance—such as alloy pipes, coated steel pipes, and high-pressure boiler tubes—especially for applications in energy, offshore, nuclear, and municipal engineering sectors.

Global Demand Tilting Toward New Energy and Environmental Projects: The acceleration of clean energy developments—including hydrogen, wind, and solar—has raised requirements for material quality, safety, and precision. At the same time, municipal pipeline upgrades and water treatment systems are steadily increasing demand for corrosion-resistant pipes, such as plastic-coated and FBE-coated steel pipes.

Green and Low-Carbon Manufacturing as a New Development Direction: As a high-energy, high-emission industry, the steel sector is under pressure to adapt to global carbon reduction goals. Steel pipe manufacturers must optimize energy use, adopt energy-saving equipment, improve process efficiency, and pursue green certifications and eco-friendly materials to enhance market competitiveness.

Digital Supply Chains and Smart Manufacturing as Core Drivers: In response to ongoing steel pipe supply chain challenges, more companies are embracing digital transformation—investing in smart warehousing, automated production lines, and traceability systems to improve operational efficiency and reduce manufacturing and inventory costs.

Stronger Regional Supply Chain Collaboration: Faced with global trade uncertainties, steel pipe enterprises are strengthening partnerships with raw material suppliers, coating providers, and logistics companies. By building more resilient supply networks locally or regionally, they can better control costs, ensure timely delivery, and reduce risk exposure.

Deepening International Market Expansion: With the Belt and Road Initiative and growing infrastructure investment in emerging markets, export-oriented companies must continue to align with international standards (such as API, ASTM, EN, and AS/NZS), improve certification systems, and enhance localized services to remain competitive globally.

How to Respond to Supply and Demand Fluctuations in the Steel Pipe Market

Fluctuations in the steel pipe market are driven by a combination of factors, including global economic cycles, raw material price volatility, policy adjustments, and geopolitical risks. To mitigate these uncertainties, manufacturers, traders, and downstream buyers must adopt flexible and resilient strategies to manage operational risks, stabilize cost structures, and safeguard their supply chains. Key response strategies include:

Establishing a Diversified Supply Chain: Relying on a single source can be risky during market volatility. Companies should develop multiple sourcing channels for raw materials, transportation, and processing to build a more flexible and resilient supply network. In global trade, forming long-term partnerships with reliable suppliers helps reduce the impact of steel pipe supply chain challenges.

Implementing Long-Term Procurement and Price Locking Mechanisms: During periods of significant steel pipe price fluctuation, companies can sign long-term contracts with upstream suppliers to lock in raw material costs and hedge against short-term volatility. Additionally, futures contracts or other financial tools may be used to manage price risks, particularly for large-scale procurement projects.

Building Intelligent Inventory and Forecasting Systems: Leveraging ERP platforms, big data analytics, and market forecasting tools allows companies to track steel pipe demand cycles and price trends in real time. This helps optimize inventory levels and avoid losses from under-purchasing during low-price periods or overstocking at peak prices.

Optimizing Product Structure and Increasing High-Value Offerings: When demand weakens or competition intensifies, low-margin products may not sustain profitability. By shifting to higher-value products—such as alloy pipes, corrosion-resistant coated steel pipes, and specialized applications—companies can enhance their market position and maintain steady demand in niche segments.

Strengthening Customer Relations and Downstream Coordination: Developing long-term cooperation models with key customers—such as annual supply plans, flexible delivery terms, or price adjustment clauses—can improve customer retention and ensure more stable deliveries even during periods of market volatility.

Controlling Production Costs and Improving Operational Efficiency: As steel pipe production costs rise, companies must focus on upgrading equipment, streamlining processes, and adopting smart manufacturing technologies to reduce energy and labor expenses. Strong cost control is essential for withstanding pressure in a volatile market.

Fluctuations in the steel pipe market are an undeniable challenge, but with flexible response strategies and effective management, companies can find opportunities in times of change and maintain competitiveness. Whether dealing with market uncertainties or exploring ways to innovate products and control costs, timely response measures are crucial!

If you have any questions regarding the steel pipe market or related products, feel free to contact us. We are dedicated to providing professional solutions and services to help you seize opportunities in the steel pipe industry. If you found this article helpful, don’t forget to like and share it with more colleagues and friends, so that more people can benefit!