Your ASTM A252 Pile pipe manufacturer in China

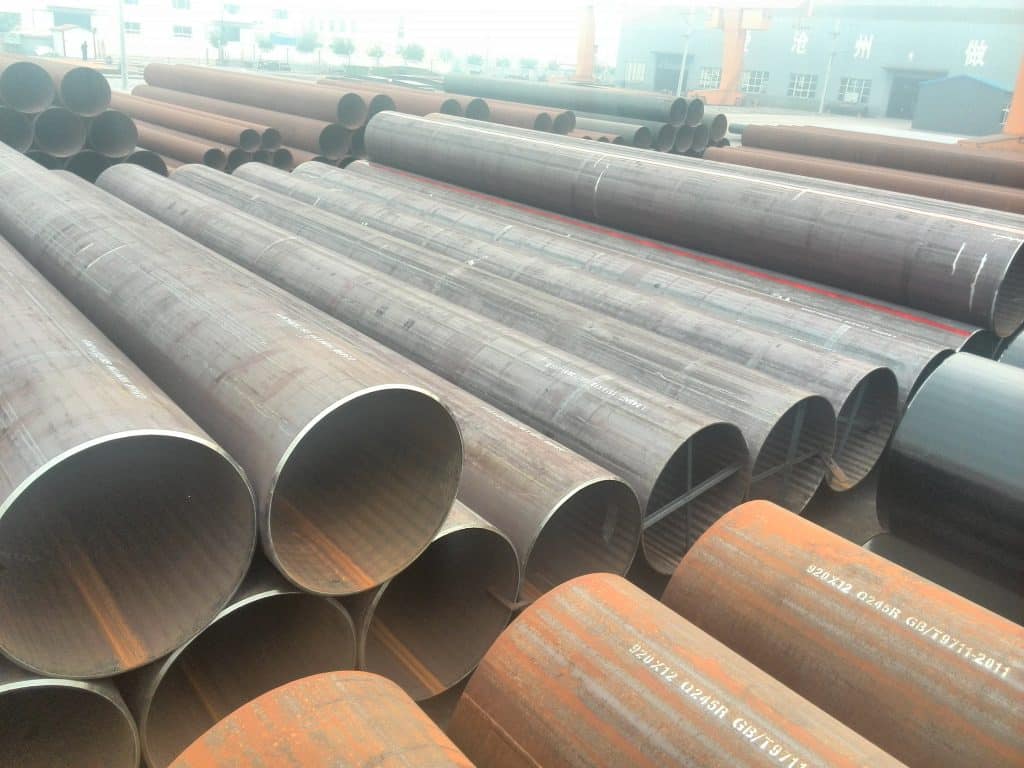

Longma produces and stocks a full range of ASTM A252 Pile pipes. Manufacturing method: ERW, LSAW, DSAW. Steel pipe piles of cylindrical shape, in which the steel cylinder acts as a permanent load-carrying member, or as a shell to form cast-in-place concrete piles.

- Grades: 1,2,3

- Out Diameter: 219.1-1016mm(8″-40″)

- Wall Thickness: 8.18-25mm

- Length: 3-18 meters

Our Certifications

Our ASTM A252 Pile pipe Product List

Longma produce & export EN10210/EN10219 S235JRH/S355JRH/S355J2H Hot Finished Structural Hollow Section since 2003.

ASTM A252 Pipe Pile

ASTM A252 GR3 Steel Pipe

ASTM A252 Grade 2 Pile Piping

ASTM A252 Seamless Steel Pipe

ASTM A252 Welded Steel Pipe

ASME SA252 Grade 3 Pipe Pile

ASTM A252 Mild Steel Pipe

ASTM A252 Steel Piling Pipe

ASTM A252 Grade 1/2/3 Piling Pipe

About Longma

- Foundin 2003, specialized in produce ERW, LSAW, DSAW steel pipes with an annual output of 300,000 tons.

- Two factories, 200,000 square meters of plant.

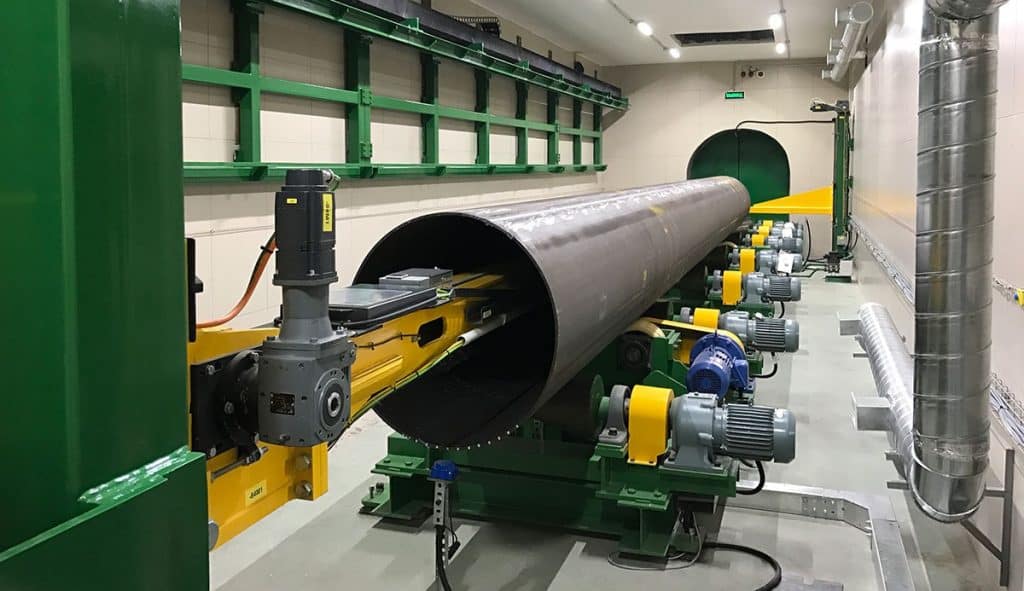

- Advanced production equipment imported from Germany, 16 JCO production lines.

- More than 300 employees and more than 60 technicians provide efficient production operations and technical services.

- API 5L(No. 5L-0685, Expiration date: 16th,Nov,2024), ISO9001, ISO14001, ISO18001, FPC certificates.

- Exports high quality steel pipes to more than 60 countries around the world.

ASTM A252 Pile pipe Production Line

Annual output of 300,000 tons of LSAW steel pipes, with out diameter Φ406mm- 1626mm (16″ – 64″), wall thickness 6.0mm- 75mm (1/4″ – 3″), length 18 meters max.

X-Ray Testing

Ultrasonic Testing

Tack Welding

Plate Ultrasonic Testing

Pipe Forming

Pipe End Bevelling

Mechanical Expansion

Hydrostatic Pipe Testing

Our Advantages For ASTM A252 Pile pipe

Complete Specifications

Good Quality

Fast Delivery

Quick Quotation

Accept Small Quantity Order

Complete Certificate

Technical Data For ASTM A252 Pile Pipe

| Composition, % | C, max | Si, max | Mn, max | P, max | S, max |

|---|---|---|---|---|---|

| Grade 1 | 0.26 | 0.45 | 1.6 | 0.05 | 0.03 |

| Grade 2 | 0.26 | 0.45 | 1.6 | 0.05 | 0.03 |

| Grade 3 | 0.26 | 0.45 | 1.6 | 0.05 | 0.03 |

The steel shall contain no more than 0.050% phosphorous.

| Mechanical Property | Grade 1 | Grade 2 | Grade 3 |

|---|---|---|---|

| Minimum Yield strength ReH MPa | 205 | 240 | 310 |

| Tensile strength Rm MPa | 345 | 415 | 455 |

| Minimum elongation A % | 30 | 25 | 20 |

| Wall Thickness | -12.5% |

|---|---|

| Weight per foot | The weight of any individual length of pipe shall not vary more than 15% over or 5% under the weight specified. Each individual length shall be weighed separately. |

| Outside diameter | ±1%D |

Nowadays, ASTM A252 pipe piling is being developed for use in a direction with deep distances and large diameters, since structures, buildings, and bridges are becoming increasingly tall, even super tall.

Piling pipe has a cylindrical design that bears weight and is suitable for a wide range of applications, including

- Buildings,

- Retaining walls,

- Different structures that need a tough base.

This guarantees that the construction is solid, stable, and of the greatest quality, ensuring toughness that satisfies international quality standards. The large diameter of the pipe prevents it from breaking under the weight of the structure or building. The pipe is also essential in stabilizing the foundation of the Retaining wall.

Different structures need a tough base material that can resist different types of loads without bending or breaking. In conclusion, piling pipes have a large variety of applications due to their durability and strength.

Frequently Asked Questions

Here are some common questions and answers. If you still have questions, don’t hesitate to contact us.

1. What is ASTM A252 specification?

ASTM A252 is the standard specification for welded and seamless steel pipe piles. It covers the nominal wall thickness of cylinder shape steel pipe, rectangular pipe is not included. These round pipes are used for piling purposes, playing as a permanent role of load carrying and bearing the pressure.

2. What is the difference between ASTM A500 and ASTM A252?

All grades are produced to a lower strength than A500. There are no chemical composition requirements in ASTM A252. The variable chemistry may affect the members’ weldability. The tolerances in A252 are more lenient than A500 for wall thickness and it has no tolerance for straightness.

3. What's the characteristic Features of ASTM A252 Pipes?

Steel piles made according to ASTM A252 specifications can be seamless, electric resistance welded, flash or fusion welded, longitudinal submerged arc welded (LSAW), and submerged helical arc welded (HSAW), or SSAW.

The seams of ASTM A252 welded piles should be helical-butt, helical-cap, or longitudinal.

ASTM A252 pipes get made using hot rolling, cold drawing, open-hearth, basic-oxygen, or electric furnace processes.

Grade 3 pipes made according to this specification have a higher tensile and yield strength of 455 Mpa and 310 MPa, respectively. This enhanced strength makes them a great fit for piling projects as they can weather the harsh driving force exerted by pile drivers onto the steel pipe piles.

When used in piling, ASTM pipe piles can be open or closed-ended, depending on the soil requirements.

Unlike other specifications, a hydrostatic test is not required in ASTM A252 pipes. Since these pipes provide stability to project foundations, they often get filled with concrete instead of being used to transport liquids. This factor makes the test unnecessary in these steel pipe piles.4. What are the uses of ASTM A252 Grade 3 Steel Pipes in Piling?

In piling, pre-made, heavy-duty tubing gets driven into the ground at specific angles and spots based on the recommendations of the geotechnical engineer. Pipes made under ASTM A252 Grade 3 are particularly well adapted for this purpose due to their enhanced tensile properties. This extra strength is necessary because vehicles like piles drivers and hydraulic hammers pound these piles into the soil with extreme force. The piles must be strong enough to withstand the onslaught of force.

This step is necessary because driven piles usually provide more support than drilled piles because they get inserted without drilling a hole in the ground first. These pipes displace the soil on entering, and the friction and pressure result in a more compact and secure foundation.

5. What is the Length Requirement for ASTM A252 Pipes?

The length specs for ASTM A252 pipes are as follows:

Single Random Length (SRL)- 16 to 15 feet

Double Random Length (DRL)- Average 35 ft, with a minimum length of 25 feet.

Uniform lengths under ASTM A252 should be as specified with an available variation of +/- 1 inch.6. What is the Reference Standards for ASTM A252 Grade 3 Pipe Pile Production?

ASTM A941 provides the terminology for different types of steel used in STM A252 pipe pile production, including stainless steel, alloy, and carbon steel.

ASTM A751 provides the basis for the test for the chemical analysis of steel pipe piles

ASTM A370 provides the inspection guides and terminology for the mechanical analysis of steel pipe piles.

E29 helps confirm the specification conformity of the steel pipe piles to ASTM A252 Grade B standards. It provides practice for digits to be used in the conformance test results.

Featured Case For ASTM A252 Pile Pipe

API 5L PSL2 X70M LSAW Pipe

- Size: 914.4*22.23*12000MM

- Country: Agentina

- Client say: This is not our first cooperation, Longma’s product quality and service has always been very good, which is the reason why we continue......

APL 5L PSL1 B LSAW Pipe

- Size: 813*10mm

- Country: Georgia

- Client say: The delivery time I asked for was very short, but they always finished on time. They have very strong organizational and coordination skills. ......

EN10210 S355J2H Hollow Section

- Size: 815mm*100mm

- Country: Poland

- Client say: The steel pipes I purchased are used for equipment manufacturing and special engineering, which have extremely strict requirements for product quality. The production......

ASTM A691 1-1/4Cr Cl22 EFW Steel Pipe

- Size: 508*20.62mm

- Country: Singapore

- Client say: Although our order quantity is not large, Longma has been very diligent to help us complete the production and provide relevant documents.

Request Free Quote

Get In Touch

How Can We Help?

Longma experienced engineers are here to guide you through every critical step in your project.

Please do not hesitate to contact us.