Blog

- All

- Knowledge

- News

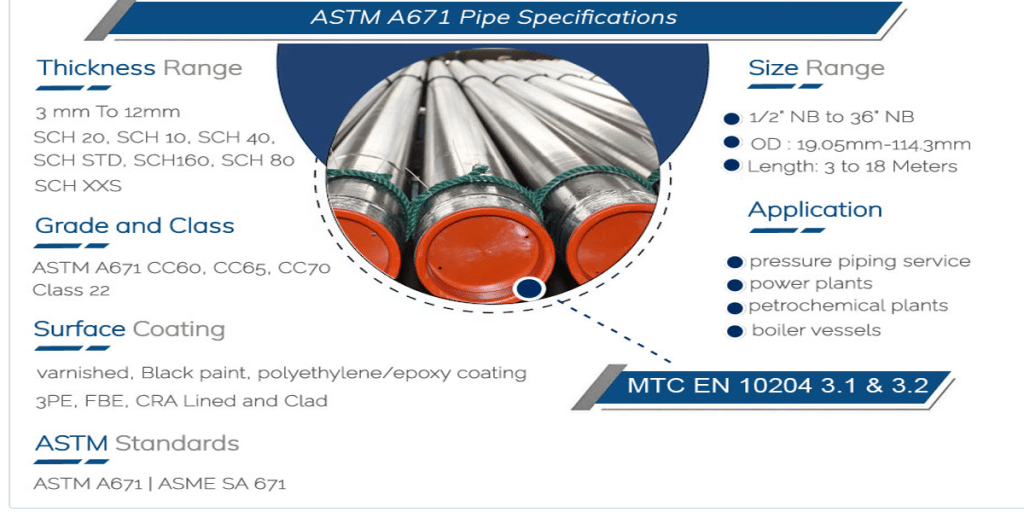

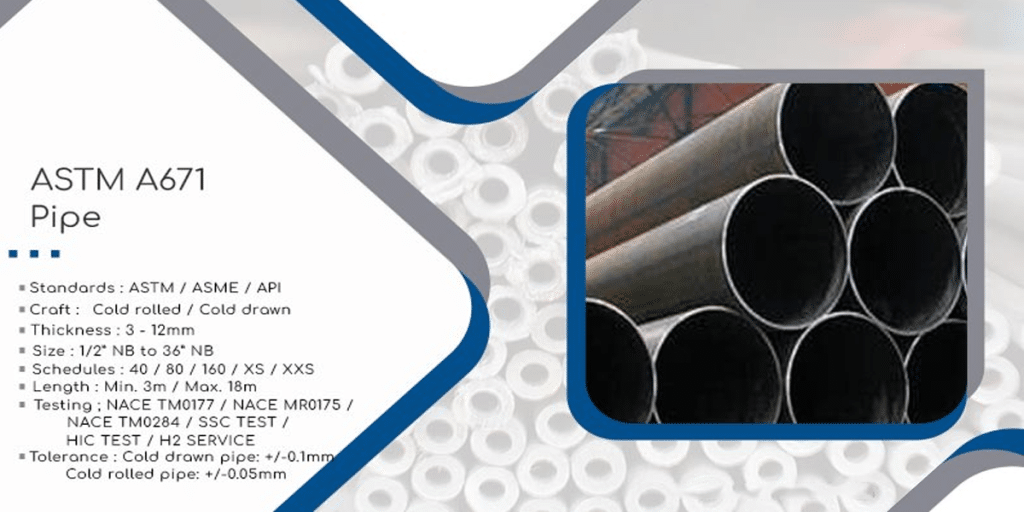

ASTM A671 VS ASTM A672: Raw materials, Performances, Applications (Comparison of ASTM A671 and ASTM A672 Standards and Material Properties) In the steel industry, ASTM A671 VS ASTM A672 are important standards developed by the American Society for Testing and Materials (ASTM). They are primarily used to regulate the production and application of electric fusion-welded steel pipes. Understanding the material properties specified in these two standards is crucial for selecting industrial pipelines. This article will conduct a detailed comparative analysis…

ASTM A671 VS ASTM A672: Raw materials, Performances, Applications (Comparison of ASTM A671 and ASTM A672 Standards and Material Properties) In the steel industry, ASTM A671 VS ASTM A672 are important standards developed by the American Society for Testing and Materials (ASTM). They are primarily used to regulate the production and application of electric fusion-welded steel pipes. Understanding the material properties specified in these two standards is crucial for selecting industrial pipelines. This article will conduct a detailed comparative analysis… Analysis of National Standards Corresponding to EN 10219-1 & 2 Overview of EN 10219-1 & 2 Standards The EN 10219 series standards (including EN 10219 2006, BS EN 10219-1 2006, BS EN 10219 2 2006, and EN 10219 2 2006) apply to welded square tubes, rectangular tubes, and other cold-formed hollow section products made of non-alloy steel and fine-grained structural steel. These products are widely used in fields such as steel structures, support components, bridges, and machinery manufacturing. Among them,…

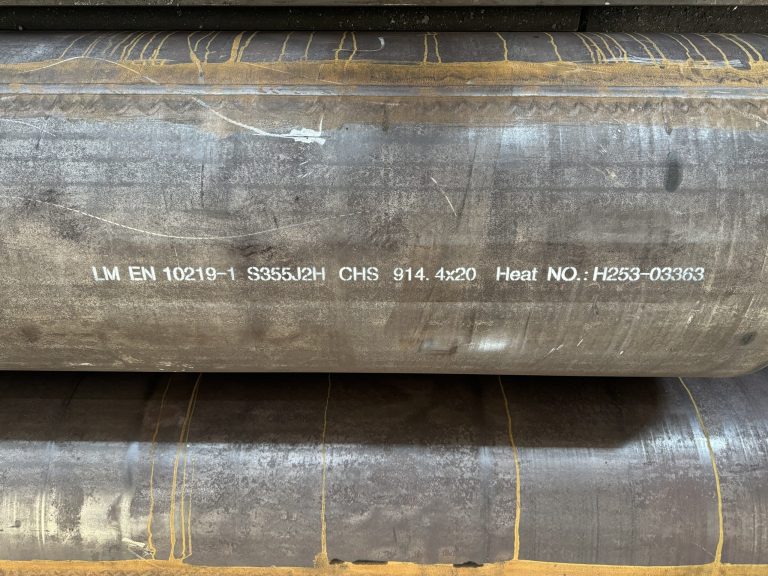

Analysis of National Standards Corresponding to EN 10219-1 & 2 Overview of EN 10219-1 & 2 Standards The EN 10219 series standards (including EN 10219 2006, BS EN 10219-1 2006, BS EN 10219 2 2006, and EN 10219 2 2006) apply to welded square tubes, rectangular tubes, and other cold-formed hollow section products made of non-alloy steel and fine-grained structural steel. These products are widely used in fields such as steel structures, support components, bridges, and machinery manufacturing. Among them,… In steel structures, equipment manufacturing, and construction projects, are you also struggling to decide which steel pipe to choose? Especially when it comes to EN 10219 vs EN 10210, they may look similar, but their uses differ greatly. One is a cold-formed steel pipe, the other is a hot-formed steel pipe—similar appearance, but with different performance, costs, and application scenarios. How can you quickly tell them apart? How to strike the right balance between structural safety, processing efficiency, and budget?…

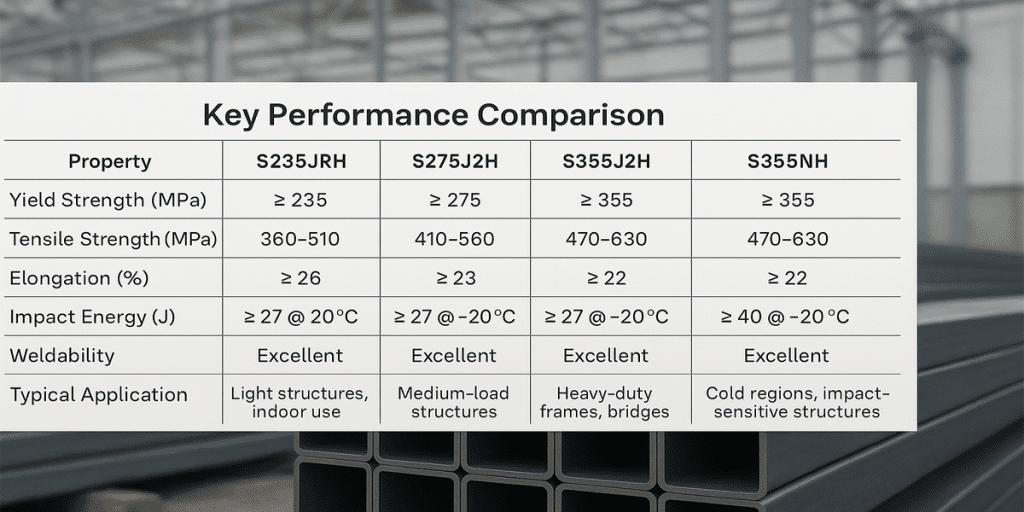

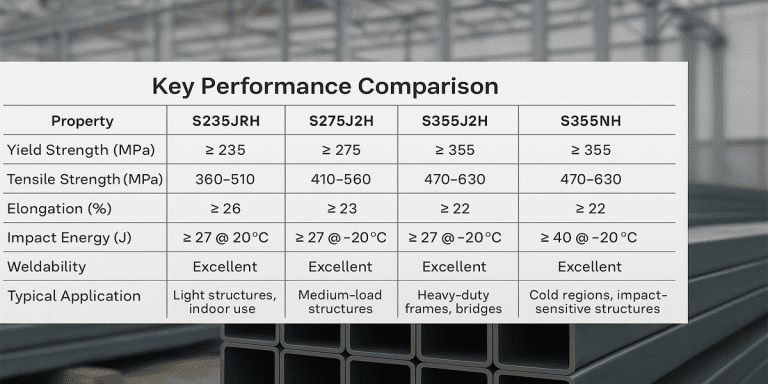

In steel structures, equipment manufacturing, and construction projects, are you also struggling to decide which steel pipe to choose? Especially when it comes to EN 10219 vs EN 10210, they may look similar, but their uses differ greatly. One is a cold-formed steel pipe, the other is a hot-formed steel pipe—similar appearance, but with different performance, costs, and application scenarios. How can you quickly tell them apart? How to strike the right balance between structural safety, processing efficiency, and budget?… As modern construction and engineering projects increasingly pursue efficiency and lightweight design, cold-formed steel tubes are becoming a key choice in structural design. Recognized as one of the leading European standards, EN 10219 is being widely adopted across various projects, especially for its advantages in high strength, sustainability, and precision manufacturing. This article offers a quick Introduction to the EN 10219 Standard, while also addressing common topics such as EN 10219 Rectangular and Square Tube Specifications Explained, Differences Between S355J2H…

As modern construction and engineering projects increasingly pursue efficiency and lightweight design, cold-formed steel tubes are becoming a key choice in structural design. Recognized as one of the leading European standards, EN 10219 is being widely adopted across various projects, especially for its advantages in high strength, sustainability, and precision manufacturing. This article offers a quick Introduction to the EN 10219 Standard, while also addressing common topics such as EN 10219 Rectangular and Square Tube Specifications Explained, Differences Between S355J2H… Tired of slow, outdated packaging equipment? Discover the innovative stainless steel long tube packaging machine—also known as a fully automatic single-tube film packaging system. This modern solution transforms the way long steel tubes are packed, ensuring efficiency, safety, and consistency. Designed for compatibility with various packaging materials like polyethylene and plastic films, this machine significantly reduces labor demands by operating automatically. It protects the quality of the tubes throughout the entire packaging process. Let’s explore how this cutting-edge machine works.…

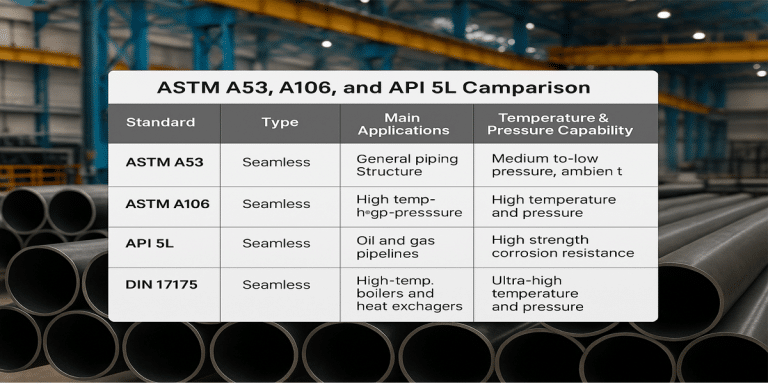

Tired of slow, outdated packaging equipment? Discover the innovative stainless steel long tube packaging machine—also known as a fully automatic single-tube film packaging system. This modern solution transforms the way long steel tubes are packed, ensuring efficiency, safety, and consistency. Designed for compatibility with various packaging materials like polyethylene and plastic films, this machine significantly reduces labor demands by operating automatically. It protects the quality of the tubes throughout the entire packaging process. Let’s explore how this cutting-edge machine works.… In the wave of continuous global industrial upgrades, steel pipe standards and selection have become a focal point for many companies. Whether in oil and gas pipeline projects or high-temperature, high-pressure boiler applications, how to choose the right steel pipe standard directly affects project safety, costs, and the convenience of later maintenance. Faced with a wide variety of specifications on the market—such as ASTM A53, ASTM A106, and API 5L—many engineering professionals are seeking a practical steel pipe selection guide…

In the wave of continuous global industrial upgrades, steel pipe standards and selection have become a focal point for many companies. Whether in oil and gas pipeline projects or high-temperature, high-pressure boiler applications, how to choose the right steel pipe standard directly affects project safety, costs, and the convenience of later maintenance. Faced with a wide variety of specifications on the market—such as ASTM A53, ASTM A106, and API 5L—many engineering professionals are seeking a practical steel pipe selection guide… With the rapid development of modern industry and infrastructure, steel pipes have become indispensable structural materials. Whether in construction projects or pipeline systems in the oil and gas industry, steel pipes play a crucial role. Faced with a wide variety of steel pipe types on the market, choosing the right steel pipe type has become a critical issue for engineers and procurement professionals. Welded steel pipes and seamless steel pipes, as two major mainstream products, each have unique advantages and…

With the rapid development of modern industry and infrastructure, steel pipes have become indispensable structural materials. Whether in construction projects or pipeline systems in the oil and gas industry, steel pipes play a crucial role. Faced with a wide variety of steel pipe types on the market, choosing the right steel pipe type has become a critical issue for engineers and procurement professionals. Welded steel pipes and seamless steel pipes, as two major mainstream products, each have unique advantages and… As the energy, chemical, and power industries continue to evolve rapidly, the selection of steel pipe standards for industrial applications has become increasingly critical. With growing attention to material performance and cost-effectiveness, choosing the right specification that fits specific working conditions is a common challenge for engineers and procurement professionals alike. Standards such as ASTM A671, API 5L, and ASTM A106 represent some of the most widely used options, each catering to different pressure levels, temperature environments, and structural demands.…

As the energy, chemical, and power industries continue to evolve rapidly, the selection of steel pipe standards for industrial applications has become increasingly critical. With growing attention to material performance and cost-effectiveness, choosing the right specification that fits specific working conditions is a common challenge for engineers and procurement professionals alike. Standards such as ASTM A671, API 5L, and ASTM A106 represent some of the most widely used options, each catering to different pressure levels, temperature environments, and structural demands.… Against the backdrop of a global shift in energy structures, multinational infrastructure projects are advancing at an unprecedented pace, particularly in sectors like natural gas, oil, and power. As a critical material in pressure-bearing transportation systems, ASTM A671 steel pipes have gained increasing prominence in the material lists of international energy projects due to their excellent mechanical properties and reliable weldability. Whether in Middle Eastern LNG terminals or energy corridors between Central and South Asia, ASTM A671 has proven itself…

Against the backdrop of a global shift in energy structures, multinational infrastructure projects are advancing at an unprecedented pace, particularly in sectors like natural gas, oil, and power. As a critical material in pressure-bearing transportation systems, ASTM A671 steel pipes have gained increasing prominence in the material lists of international energy projects due to their excellent mechanical properties and reliable weldability. Whether in Middle Eastern LNG terminals or energy corridors between Central and South Asia, ASTM A671 has proven itself… With the growing global demand for clean energy, natural gas—as an efficient and environmentally friendly fuel—is increasingly used in power plants and thermal energy stations. In the face of complex and variable operating conditions, selecting steel pipe materials with excellent performance and industry-standard compliance is especially important. As a welded steel pipe specifically designed for high strength and corrosion resistance, ASTM A672 is gradually becoming the preferred choice for natural gas pipeline projects and thermal station pipe selection. This article…

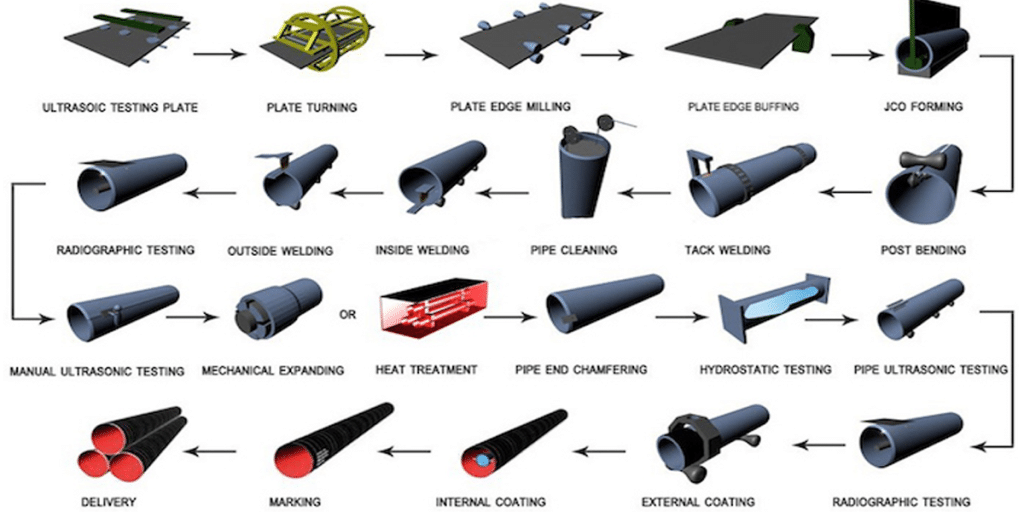

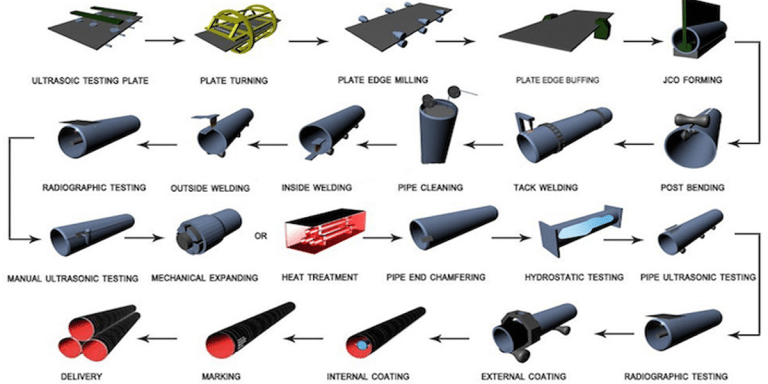

With the growing global demand for clean energy, natural gas—as an efficient and environmentally friendly fuel—is increasingly used in power plants and thermal energy stations. In the face of complex and variable operating conditions, selecting steel pipe materials with excellent performance and industry-standard compliance is especially important. As a welded steel pipe specifically designed for high strength and corrosion resistance, ASTM A672 is gradually becoming the preferred choice for natural gas pipeline projects and thermal station pipe selection. This article… With the rapid expansion of global energy infrastructure and high-pressure transmission systems, the optimization and standardization of pressure pipe steel manufacturing steps have become a focal point in the industry. As a critical material widely used in oil, gas, power, and chemical sectors, ASTM A672 steel pipes are increasingly favored by manufacturers and engineering firms for their excellent pressure resistance and structural reliability. In high-demand applications where safety and reliability are paramount, ensuring that each pipe complies with the ASTM…

With the rapid expansion of global energy infrastructure and high-pressure transmission systems, the optimization and standardization of pressure pipe steel manufacturing steps have become a focal point in the industry. As a critical material widely used in oil, gas, power, and chemical sectors, ASTM A672 steel pipes are increasingly favored by manufacturers and engineering firms for their excellent pressure resistance and structural reliability. In high-demand applications where safety and reliability are paramount, ensuring that each pipe complies with the ASTM… With the rapid development of industrial manufacturing and infrastructure construction, steel pipes have become essential materials with increasingly stringent performance and quality requirements. Especially in the field of welded pipes, selecting products that meet standards and ensure reliability is crucial for guaranteeing both safety and economic efficiency. This article focuses on the ASTM A672 selection guide, delving into common knowledge about welded pipe usage and answering frequently asked questions in steel pipe procurement, helping you fully grasp the key points…

With the rapid development of industrial manufacturing and infrastructure construction, steel pipes have become essential materials with increasingly stringent performance and quality requirements. Especially in the field of welded pipes, selecting products that meet standards and ensure reliability is crucial for guaranteeing both safety and economic efficiency. This article focuses on the ASTM A672 selection guide, delving into common knowledge about welded pipe usage and answering frequently asked questions in steel pipe procurement, helping you fully grasp the key points… With the growing demand for high-performance transmission pipelines in industries such as energy, petrochemicals, and infrastructure, ASTM A672 steel pipes have gradually become an essential material in engineering projects. Especially under complex working conditions involving medium to high pressure, low temperatures, or welded structures, choosing the right pipe for the application environment has become a major concern for designers and procurement specialists. As one of the most representative welded steel pipes, ASTM A672 not only offers good mechanical properties and…

With the growing demand for high-performance transmission pipelines in industries such as energy, petrochemicals, and infrastructure, ASTM A672 steel pipes have gradually become an essential material in engineering projects. Especially under complex working conditions involving medium to high pressure, low temperatures, or welded structures, choosing the right pipe for the application environment has become a major concern for designers and procurement specialists. As one of the most representative welded steel pipes, ASTM A672 not only offers good mechanical properties and… With the rapid development of high-demand industries such as petrochemicals, power generation, and energy transmission, the selection of engineering pipeline materials has become a critical factor in ensuring both project safety and cost-effectiveness. As a widely adopted standard for electric-fusion-welded steel pipes used in medium to low temperature environments, ASTM A671 is commonly applied in boilers, heat exchangers, and pressure pipeline systems. Due to its excellent weldability and high strength, different grades under this specification—such as CA grade pipes, CB…

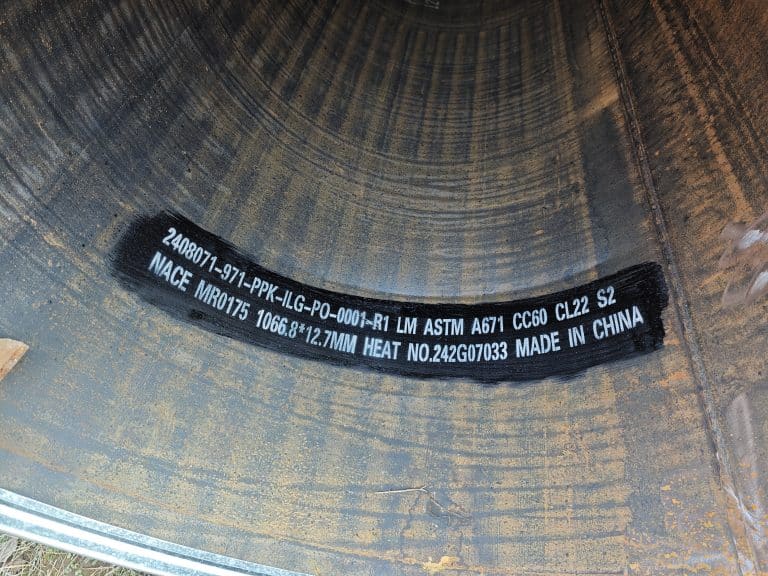

With the rapid development of high-demand industries such as petrochemicals, power generation, and energy transmission, the selection of engineering pipeline materials has become a critical factor in ensuring both project safety and cost-effectiveness. As a widely adopted standard for electric-fusion-welded steel pipes used in medium to low temperature environments, ASTM A671 is commonly applied in boilers, heat exchangers, and pressure pipeline systems. Due to its excellent weldability and high strength, different grades under this specification—such as CA grade pipes, CB… As global engineering projects increasingly demand higher standards of material quality and safety, the ASTM A671 compliance standard has become a critical benchmark in the steel pipe industry. As a typical representative of welded steel pipes, ASTM A671 pipes must not only meet stringent manufacturing specifications but also undergo third-party testing to ensure consistent and reliable product quality. The ASTM A671 MTC (Material Test Certificate) requirements in project delivery documents serve as a key basis for confirming material compliance between…

As global engineering projects increasingly demand higher standards of material quality and safety, the ASTM A671 compliance standard has become a critical benchmark in the steel pipe industry. As a typical representative of welded steel pipes, ASTM A671 pipes must not only meet stringent manufacturing specifications but also undergo third-party testing to ensure consistent and reliable product quality. The ASTM A671 MTC (Material Test Certificate) requirements in project delivery documents serve as a key basis for confirming material compliance between…