Your ASTM A691 EFW Steel Pipe manufacturer in China

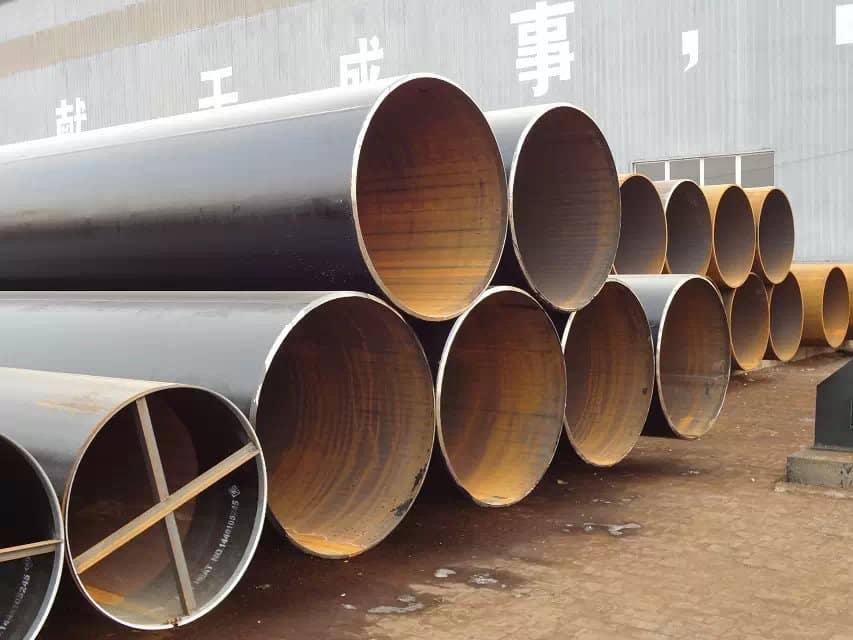

LONGMA as China leading ASTM A691 Chrome Moly EFW steel pipe manufacturer since 2003, supply tens of thousands of tons of ASTM A691 steel pipe to the world every year. These pipes are manufactured in Electric-Fusion-Welded process, and fabricated with Chrome Moly Steel Plate in ASTM A387. ASTM A691 specification covers carbon and alloy steel pipe, electric-fusion-welded with filler metal added, fabricated from pressure-vessel-quality plate of several analyses and strength levels and suitable for high-pressure service at high temperatures.

- Grade: 1Cr, 1-1/4Cr, 2-1/4Cr, 3Cr, 5Cr

- Class: 12, 20, 21, 22, 30, 32, 40, 50

- Out Diameter: 406.4-1422.2mm(16″-56″)

- Wall Thickness: 7.92-75mm

- Length: 3-18 meters

Our Certifications

Our ASTM A691 EFW Steel Pipe Product List

Longma is one of the leading ASTM A691 1Cr, 1-1/4Cr, 2-1/4Cr CL22 EFW pipes manufacturer since 2003

ASTM A691 GR 1-1/4 Cr Cl22 EFW Steel Pipe

ASTM A691 2-1/4 Cr Class 22 Pipe

ASTM A691 Grade 1.25Cr Alloy Steel Pipe

ASTM A691 Chrome Moly EFW Steel Pipe

ASTM A691 EFW Carbon And Alloy Steel Pipe

ASTM A691 High Quality Steel Pipe

Longma is one of the leading ASTM A691 1Cr, 1 1/4Cr, 2 1/4Cr CL22 EFW pipes manufacturer since 2003

- Foundin 2003, specialized in produce ERW, LSAW, DSAW steel pipes with an annual output of 300,000 tons.

- Two factories, 200,000 square meters of plant.

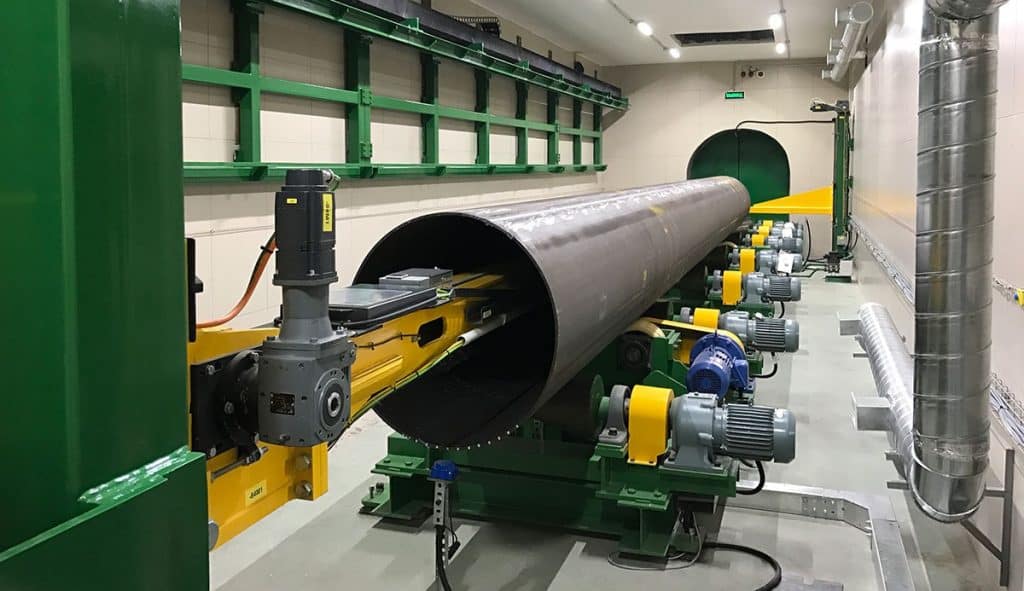

- Advanced production equipment imported from Germany, 16 JCO production lines.

- More than 300 employees and more than 60 technicians provide efficient production operations and technical services.

- API 5L(No. 5L-0685, Expiration date: 16th,Nov,2024), ISO9001, ISO14001, ISO18001, FPC certificates.

- Exports high quality steel pipes to more than 60 countries around the world.

ASTM A691 EFW Steel Pipe Production Line

Annual output of 300,000 tons of LSAW steel pipes, with out diameter Φ406mm- 1626mm (16″ – 64″), wall thickness 6.0mm- 75mm (1/4″ – 3″), length 18 meters max.

X-Ray Testing

Ultrasonic Testing

Tack Welding

Plate Ultrasonic Testing

Pipe Forming

Pipe End Bevelling

Mechanical Expansion

Hydrostatic Pipe Testing

Our Advantages For ASTM A691 EFW Steel Pipe

Complete Specifications

Good Quality

Fast Delivery

Quick Quotation

Accept Small Quantity Order

Complete Certificate

Technical Data For STM A691 EFW Steel Pipe

| Class | Heat Treatment on Pipe | Radiography, see Section | Pressure Test, see Section | |

|---|---|---|---|---|

| 10 | none | none | none | |

| 11 | none | 9 | none | |

| 12 | none | 9 | 8.3 | |

| 13 | none | none | 8.3 | |

| 20 | stress relieved, see 5.3.1 | none | none | |

| 21 | stress relieved, see 5.3.1 | 9 | none | |

| 22 | stress relieved, see 5.3.1 | 9 | 8.3 | |

| 23 | stress relieved, see 5.3.1 | none | 8.3 | |

| 30 | normalized, see 5.3.2 | none | none | |

| 31 | normalized, see 5.3.2 | 9 | none | |

| 32 | normalized, see 5.3.2 | 9 | 8.3 | |

| 33 | normalized, see 5.3.2 | none | 8.3 | |

| 40 | normalized and tempered, see 5.3.3 | none | none | |

| 41 | normalized and tempered, see 5.3.3 | 9 | none | |

| 42 | normalized and tempered, see 5.3.3 | 9 | 8.3 | |

| 43 | normalized and tempered, see 5.3.3 | none | 8.3 | |

| 50 | quenched and tempered, see 5.3.4 | none | none | |

| 51 | quenched and tempered, see 5.3.4 | 9 | none | |

| 52 | quenched and tempered, see 5.3.4 | 9 | 8.3 | |

| 53 | quenched and tempered, see 5.3.4 | none | 8.3 |

| Pipe Grade | Type of Steel | ASTM Specification | HB, max A | |

|---|---|---|---|---|

| Number | Grade | |||

| CM-65 | carbon-molybdenum steel | A204/A204M | A | 201 |

| CM-70 | carbon-molybdenum steel | A204/A204M | B | 201 |

| CM-75 | carbon-molybdenum steel | A204/A204M | C | 201 |

| CMSH-70 | carbon-manganese-silicon steel, normalized | A537/A537M | 1 | |

| CMS-75 | carbon-manganese-silicon steel | A299/A299M | … | … |

| CMSH-80 | carbon-manganese-silicon steel, quenched and tempered | A537/A537M | 2 | |

| ½ CR | ½% chromium, ½% molybdenum steel | A387/A387M | 2 | 201 |

| 1CR | 1% chromium, ½% molybdenum steel | A387/A387M | 12 | 201 |

| 1 ¼CR | 1 ¼% chromium, ½% molybdenum steel | A387/A387M | 11 | 201 |

| 2 ¼CR | 2 ¼% chromium, 1% molybdenum steel | A387/A387M | 22 | 201 |

| 3CR | 3% chromium, 1% molybdenum steel | A387/A387M | 21 | 201 |

| 5CR | 5% chromium,½% molybdenum steel | A387/A387M | 5 | 225 |

| 9CR | 9% chromium, 1% molybdenum steel | A387/A387M | 9 | 241 |

| 91 | 9% chromium, 1% molybdenum, vanadium, columbium | A387/A387M | 91 | 241 |

| A Hardness values listed are applicable to S3. | ||||

| Pipe Grade | ASTM |

|---|---|

| Specification | Post-Weld Heat-Treat |

| Temperature Range (Stress | carbon-molybdenum steel |

| Relieving), °F (°C) | Normalizing |

| Temperature, | carbon-molybdenum steel |

| max unless | carbon-manganese-silicon steel, normalized |

| otherwise noted, | carbon-manganese-silicon steel |

| °F (°C) | Quenching |

| Temperature, | ½% chromium, ½% molybdenum steel |

| max unless | 1% chromium, ½% molybdenum steel |

| otherwise noted, | 1 ¼% chromium, ½% molybdenum steel |

| °F (°C) | Tempering Temperature, |

| min, °F (°C) | 3% chromium, 1% molybdenum steel |

| CM-65 | A204/A204M |

| CM-70 | A204/A204M |

| CM-75 | A204/A204M |

| CMSH-70 | A537/A537M |

| CMS-75 | A299/A299M |

| CMSH-80 | A537/A537M |

| ½ CR | A387/A387M |

| 1 CR | A387/A387M |

| 1 ¼CR | A387/A387M |

| 2 ¼CR | A387/A387M |

| 3CR | A387/A387M |

| 5CR | A387/A387M |

| 9CR | A387/A387M |

| 91 | A387/A387M |

| min] | 1350 to 1440 [730 to 780] |

| % | 1CR | 1-1/4CR | 2-1/4 CR | 5 CR | 9 CR | 91 |

|---|---|---|---|---|---|---|

| C | 0.05-0.17 | 0.05-0.17 | 0.05-0.15 | 0.15 | 0.15 | 0.08-0.12 |

| Mn | 0.40-0.65 | 0.40-0.65 | 0.30-0.60 | 0.30-0.60 | 0.30-0.60 | 0.30-0.60 |

| P | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.020 |

| S | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.010 |

| Si | 0.15-0.40 | 0.50-0.80 | 0.50 | 0.50 | 1.00 | 0.20-0.50 |

| Cr | 0.80-1.15 | 1.00-1.50 | 2.00-2.50 | 4.00-6.00 | 8.00-10.00 | 8.00-9.50 |

| Mo | 0.45-0.60 | 0.45-0.65 | 0.90-1.10 | 0.45-0.65 | 0.90-1.10 | 0.85-1.05 |

| V | – | – | – | – | 0.04 | 0.18-0.25 |

*Grade 91 also includes restrictions on Nickel 0.40 max, Columbium 0.06-0.10, Nitrogen 0.030-0.070, Aluminum 0.02 max, titanium 0.01 max, Zirconium 0.01 max.

Class 1 Plates

| Grade | Tensile (MPa) | Yield (MPa) | Elong. (50mm) | Reduc’n of Area* |

|---|---|---|---|---|

| 1CR | 380 – 550 | 230 min | 22% min | – |

| 1-1/4CR | 415 – 585 | 240 min | 22% min | – |

| 2-1/4CR, 5CR, 9CR | 415 – 585 | 205 min | 18% min | 40% min |

| 91 | 415 – 585 | 205 min | 18% min | 40% min |

* Measured on a flat specimen

Class 2 Plates

| Grade | Tensile (MPa) | Yield (MPa) | Elong. (50 mm) | Reduc’n of Area* |

|---|---|---|---|---|

| 2 | 485 – 620 | 310 min | 22% min | – |

| 1-1/4CR | 515 – 690 | 310 min | 22% min | – |

| 1CR | 450 – 585 | 275 min | 22% min | – |

| 2-1/4CR, 5CR, 9CR | 515 – 690 | 310 min | 18% min | 40% min |

| 91 | 585 – 760 | 415 min | 18% min | – |

* Measured on a flat specimen

| Outside diameter | +/- 0.5% |

|---|---|

| Out of roundness | The difference between major and minor outside diameters 1%. |

| Alignment | Using a 10-ft 3m straightedge placed so that both ends are in contact with the pipe, 1/8in. 3mm. |

| Thickness | Minimum wall thickness at any point in the pipe shall not be more than 0.01 in 0.3mm under the specified nominal thickness. |

| Lengths | Lengths with unmachined ends shall be within -0, +1/2 inch, 0 +13mm of that specified. Lengths with machined ends shall be as agreed between manufacturer and purchaser. |

Frequently Asked Questions

Here are some common questions and answers. If you still have questions, don’t hesitate to contact us.

1. What is ASTM A691?

ASTM A691 specification covers carbon and alloy steel pipe, electric-fusion-welded with filler metal added, fabricated from pressure-vessel-quality plate of several analyses and strength levels and suitable for high-pressure service at high temperatures.

2. What is ASTM A691 1-1/4 CR CL 22?

ASTM A691 Grade 1-1/4 CR Class 22 Pipe comes under the A691 specification. This specification covers alloy steel pipes and carbon steel pipes that are fusion welded with filler materials. The pipes can also be fabricated from pressure vessel quality sheets.

3. What grades are included in the A691 standard?

The standard ASTM A691 is included grade CM-65, CM-70, CM-75, CMSH-70,CMS-75, CMSH-80, 1/2 CR, 1 CR, 1 1/4 CR, 2 1/4 CR, 3CR, 5CR, 9CR, 91.

4. What is the composition of ASTM A691?

The ASTM A691 Pipe is made with a composition of chromium, molybdenum, carbon, manganese, phosphorous, silicon, and sulfur. These pipes possess excellent corrosion and oxidation resistance properties. The ASTM A691 Gr 11 Welded Pipe is formed after welding steel with the help of a filler.

5. What areas can ASTM A691 steel pipe be used for?

ASTM A691 Alloy Steel Seamless Pipe is intended for high temperature administration use and they are utilized in different applications like HVAC and Firefighting, Hydro Carbon Processes, Plumbing, Sewage and Waterwell, Oil and Gas, and so forth.

6. What is ASTM A691 2-1/4CR pipe?

ASTM A691 2-1/4CR pipe refers Chrome Moly Welded Pipe used for high temperature and high pressure services. These pipes are manufactured in Electric-Fusion-Welded process, and fabricated with Chrome Moly Steel Plate in ASTM A387 Grade 22. ASTM A691 2-1/4CR pipes has Chrome content 2% to 2.5%, Moly 0.9% to 1.1%. This material equivalent to seamless pipe in ASTM A335 P22 pipe, and also could be made to fittings like elbws, bends, tees, reducers etc.

Featured Case For ASTM A691 EFW Steel Pipe

API 5L PSL2 X70M LSAW Pipe

- Size: 914.4*22.23*12000MM

- Country: Agentina

- Client say: This is not our first cooperation, Longma’s product quality and service has always been very good, which is the reason why we continue......

APL 5L PSL1 B LSAW Pipe

- Size: 813*10mm

- Country: Georgia

- Client say: The delivery time I asked for was very short, but they always finished on time. They have very strong organizational and coordination skills. ......

EN10210 S355J2H Hollow Section

- Size: 815mm*100mm

- Country: Poland

- Client say: The steel pipes I purchased are used for equipment manufacturing and special engineering, which have extremely strict requirements for product quality. The production......

ASTM A691 1-1/4Cr Cl22 EFW Steel Pipe

- Size: 508*20.62mm

- Country: Singapore

- Client say: Although our order quantity is not large, Longma has been very diligent to help us complete the production and provide relevant documents.

Request Free Quote

Get In Touch

How Can We Help?

Longma experienced engineers are here to guide you through every critical step in your project.

Please do not hesitate to contact us.