In the modern energy industry, the safe and efficient transportation of oil and natural gas is a critical link in ensuring global energy supply. As a vital bridge connecting oil and gas fields to end users, the quality of steel pipes used in oil pipelines directly affects the safety and stability of the transportation system. In recent years, with increasing demands for low-temperature environments and high-pressure transportation conditions, ASTM A671 standard welded steel pipes have become the preferred material for mid-to-low temperature oil and gas pipeline selection due to their excellent mechanical properties and low-temperature performance.

Especially in the recommended natural gas transmission steel pipes, ASTM A671 steel pipes have gained wide recognition for their reliable low-temperature welding performance and corrosion resistance, ensuring the long-term safe operation of gas transmission pipelines. So, what makes ASTM A671 steel pipes stand out among various steel pipes used in oil pipelines and become a key material in the oil and gas industry? Next, we will take an in-depth look at their technical advantages and application value!

Overview of ASTM A671 Steel Pipes

1. Standard Introduction

ASTM A671 is a steel pipe standard issued by ASTM International, specifically designed for welded steel pipes used in oil and gas transportation, ensuring stable performance under high pressure, low temperature, and other complex working conditions.

2. Scope of Application and Temperature Characteristics

ASTM A671 steel pipes are suitable for medium to low temperature environments, typically operating within a temperature range of -50°C to +100°C. They are especially ideal for mid-to-low temperature oil and gas pipeline selection and are widely used in natural gas transmission steel pipes and gas transportation pipelines.

3. Key Performance Requirements

ASTM A671 steel pipes have strict requirements on chemical composition, mechanical properties, low-temperature impact toughness, and welding processes to ensure excellent low-temperature weldability and corrosion resistance, guaranteeing safe operation in harsh environments.

4. Technical Advantages

Outstanding low-temperature toughness effectively prevents brittle fracture in cold environments.

Advanced welding technology ensures pipe strength and sealing performance.

Excellent corrosion resistance adapts to various complex oil and gas transportation environments.

5. Industry Applications

ASTM A671 standard welded steel pipes are widely applied in the oil and gas industry, particularly excelling in gas transportation pipelines under medium to low temperature conditions, serving as a critical material for ensuring pipeline safety.

Key Performance Advantages of ASTM A671 for the Oil and Gas Industry

1. Excellent Low-Temperature Toughness

ASTM A671 steel pipes maintain good impact toughness even at temperatures as low as -50°C, significantly reducing the risk of brittle fracture in cold conditions. This makes them especially suitable for mid-to-low temperature oil and gas pipeline selection, ensuring safe operation in extreme climates.

2. High Strength and Pressure Resistance

The standard requires the steel pipes to have high tensile and yield strength, meeting the safety demands of oil pipeline steel pipes under high-pressure transportation, ensuring the stability and durability of gas transmission pipelines.

3. Reliable Welding Performance

ASTM A671 standard welded steel pipes have strict controls on welding processes, ensuring strong and sealed joints for low-temperature welded steel pipes, minimizing leakage risks, and fitting complex oil and gas transportation systems.

4. Outstanding Corrosion Resistance

The steel material offers excellent corrosion resistance, effectively resisting corrosion from transported media and external environments, extending pipeline service life and reducing maintenance costs, making it an ideal choice for recommended natural gas transmission steel pipes.

5. Good Workability and Diverse Specifications

ASTM A671 steel pipes come in a wide range of specifications to meet various pipeline design requirements. They also have good machinability and formability, facilitating installation and on-site construction.

6. Compliance with International Standards Ensuring Quality

As an internationally recognized ASTM standard, A671 steel pipes are widely used in the global oil and gas industry, ensuring stable material quality and meeting strict safety and performance requirements.

Typical Application Scenarios of ASTM A671

1. Natural Gas Transmission Pipelines

ASTM A671 steel pipes are widely used in natural gas transmission due to their excellent low-temperature toughness and corrosion resistance. They ensure safe and stable operation of pipelines in medium to low temperature environments, meeting the stringent strength and sealing requirements of gas transmission pipelines.

2. Oil Transportation Pipelines

In oil pipeline steel pipes, ASTM A671 standard pipes are extensively applied in long-distance, high-pressure oil transportation systems due to their high strength and pressure resistance, ensuring safety and smooth flow during oil transport.

3. Low-Temperature Storage and Transportation Facilities

ASTM A671 steel pipes suitable for low-temperature welding meet the demanding conditions of low-temperature storage and transportation facilities, preventing material brittleness caused by low temperatures and ensuring long-term reliable operation.

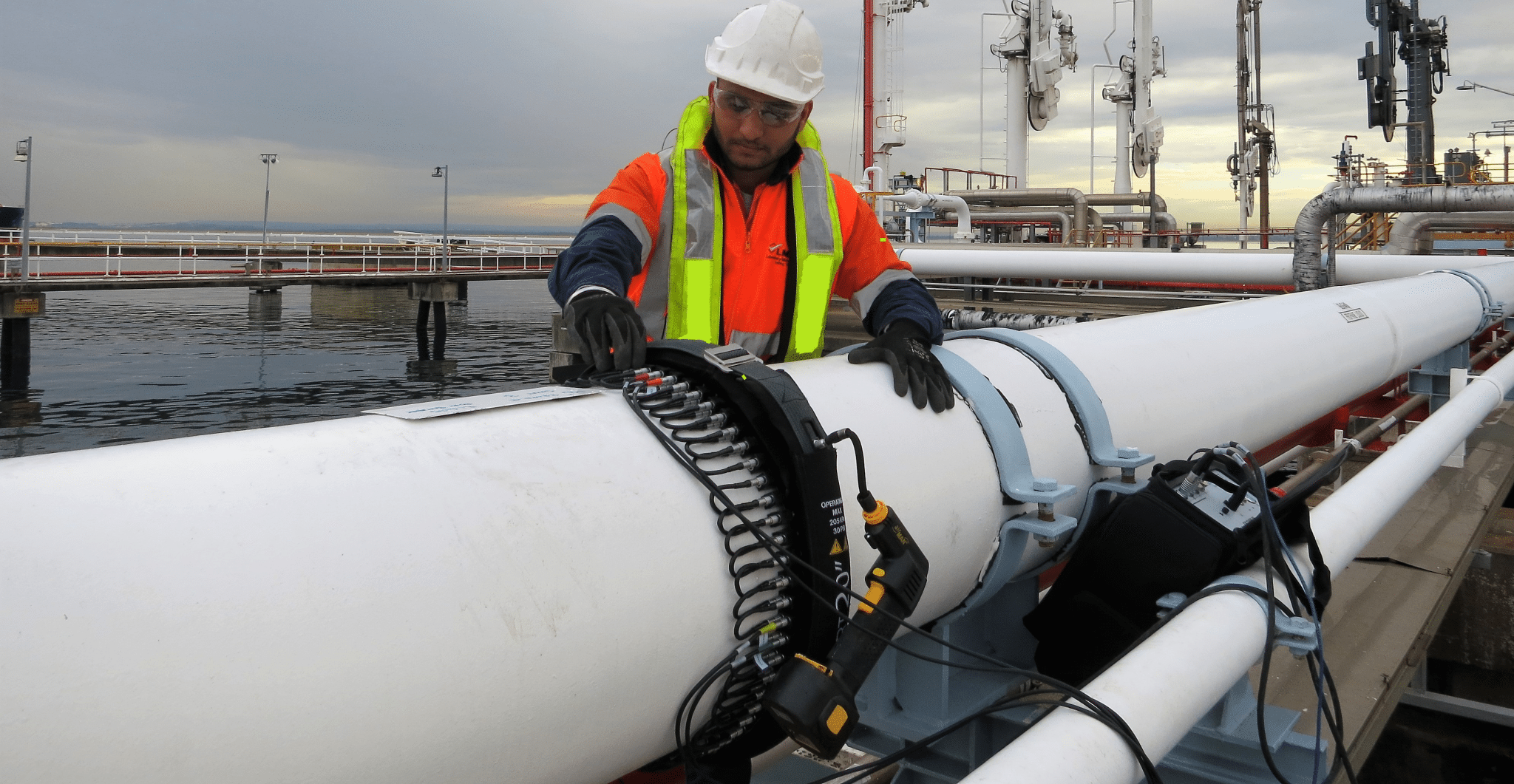

4. Offshore Oil and Gas Platform Pipelines

Offshore environments impose high demands on steel pipes for corrosion resistance and mechanical performance. ASTM A671 steel pipes, with their excellent corrosion resistance and weldability, have become a key material for offshore oil and gas platform pipelines.

5. Petrochemical Industry Auxiliary Pipelines

In the petrochemical industry, ASTM A671 standard steel pipes are also used in auxiliary pipeline construction, supporting the transportation of gases and liquids during production, ensuring the safety and stability of pipeline systems.

Comparison of ASTM A671 with API 5L, ASTM A106, and ASTM A672

1. Standard Scope and Primary Applications

ASTM A671: Specifically designed for welded steel pipes used in mid-to-low temperature oil and gas transmission, focusing on gas transmission pipelines and low-temperature weldability with excellent toughness.

API 5L: The primary global standard for oil and gas transmission pipelines, covering high-strength pipes for oil and natural gas, emphasizing high pressure and high strength applications.

ASTM A106: Mainly for seamless high-temperature service pipes, suitable for steam, oil, and gas transmission at elevated temperatures with excellent high-temperature performance.

ASTM A672: Targets thick-walled and large-diameter welded pipes, widely used in oil, natural gas, and structural applications, emphasizing corrosion resistance and mechanical properties.

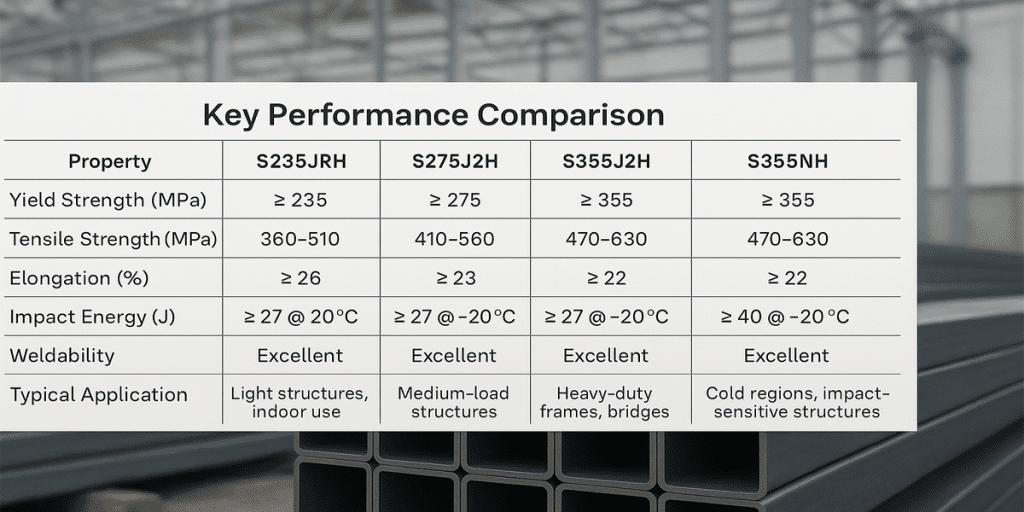

2. Material Performance Comparison

ASTM A671: Excellent low-temperature impact toughness, suitable for pipelines operating at temperatures as low as -50°C and above in mid-to-low temperature conditions.

API 5L: Offers multiple strength grades (e.g., X42 to X80) to meet high pressure and high strength requirements.

ASTM A106: Superior high-temperature performance but generally lower low-temperature toughness compared to A671.

ASTM A672: Emphasizes corrosion resistance and mechanical strength, suitable for thick-walled pipeline needs with strong pressure resistance.

3. Weldability

ASTM A671: Strict welding process requirements ensuring low-temperature weld toughness, suitable for low-temperature welded steel pipes.

API 5L: Good weldability, compatible with various welding methods for pipeline fabrication.

ASTM A106: Seamless pipes with minimal welding, mostly used in high-temperature and high-pressure applications.

ASTM A672: Welded pipes designed for large pipeline projects with stringent weld quality control.

4. Temperature Range

ASTM A671: -50°C to +100°C, designed for mid-to-low temperature oil and gas transmission.

API 5L: Wide temperature range, suitable for extreme temperatures and high-pressure conditions.

ASTM A106: Suitable for high-temperature service up to approximately 427°C (800°F).

ASTM A672: Suitable for ambient to moderate temperature environments, depending on material grade.

5. Industry Applications and Recommendations

ASTM A671: Recommended for natural gas transmission pipelines, especially in low-temperature environments.

API 5L: The preferred standard for oil and gas transmission pipelines, suitable for high-pressure, long-distance transport.

ASTM A106: Used mainly for high-temperature steam and oil pipelines, particularly in refining and elevated temperature service.

ASTM A672: Used in large structural and oil & gas pipelines, emphasizing corrosion resistance and mechanical strength.

How to Ensure Quality and Standard Compliance of ASTM A671 Steel Pipes?

1. Select Qualified Suppliers

Prioritize purchasing from steel pipe manufacturers or suppliers with valid certifications and a good industry reputation.

Suppliers should have ISO quality management system certification and relevant pipe manufacturing certifications such as API and ASTM.

2. Strict Material Inspection and Acceptance

Incoming materials must be accompanied by complete Mill Test Reports (MTR), clearly stating chemical composition, mechanical properties, dimensional tolerances, etc., in accordance with ASTM A671 standards.

Perform chemical composition analysis, tensile tests, impact tests (especially low-temperature impact toughness), and other physical performance inspections.

3. Conduct Non-Destructive Testing (NDT)

Use Ultrasonic Testing (UT), Radiographic Testing (RT), Magnetic Particle Testing (MT), and other NDT methods to detect weld and internal defects, ensuring weld quality and pipe integrity.

Regularly conduct in-process quality control tests during manufacturing to prevent defects.

4. Verify Dimensions and Appearance

Check pipe wall thickness, outer diameter, and length to ensure compliance with standards and design requirements.

Inspect the pipe surface for cracks, dents, corrosion, and other defects to ensure surface quality.

5. Control Welding Process and Weld Quality

Ensure welding procedures meet ASTM A671 requirements, especially for low-temperature welded steel pipes, including preheating, welding parameters, and weld inspection.

Conduct mechanical and impact toughness testing of weld joints to guarantee weld performance at low temperatures.

6. Third-Party Testing and Certification

Engage authoritative third-party inspection agencies for sampling inspection and certification of materials and products.

Third-party reports enhance confidence during procurement and project acceptance.

7. Strict Storage and Transportation Management

Prevent mechanical damage and corrosion during storage and transportation to ensure pipes meet standards upon delivery.

Use proper stacking methods and protective measures to avoid deformation or contamination.

As the oil and gas industry’s requirements for pipe performance continue to rise, ASTM A671 steel pipes stand out as an essential material thanks to their excellent low-temperature toughness and weldability. Only through strict quality control and adherence to standards can we ensure the safe and stable operation of pipeline systems and promote efficient energy transportation!

If you found this article helpful, please give it a thumbs up and share it with your colleagues and friends. The more people understand the importance of ASTM A671 steel pipes and how to ensure their quality compliance, the better the industry can develop. Your support is our greatest motivation to keep delivering valuable content!