ASTM A671 VS ASTM A672: Raw materials, Performances, Applications

(Comparison of ASTM A671 and ASTM A672 Standards and Material Properties)

In the steel industry, ASTM A671 VS ASTM A672 are important standards developed by the American Society for Testing and Materials (ASTM). They are primarily used to regulate the production and application of electric fusion-welded steel pipes. Understanding the material properties specified in these two standards is crucial for selecting industrial pipelines. This article will conduct a detailed comparative analysis of these two standards in terms of their scope of application, steel grade classification, raw material sheet standards, differences in performance characteristics, application fields, and recent key projects.

Scope of Application of the Standards(ASTM A671 VS ASTM A672)

- ASTM A671 Standard

The ASTM A671 standard applies to electric fusion-welded steel pipes for use in atmospheric and cryogenic conditions. A671 pipes, manufactured from high-quality pressure vessel sheets with various strength classes and compositions, are suitable for high-pressure applications at both atmospheric and cryogenic temperatures. Nominally, the standard applies to pipes with an outer diameter of 16 inches (400 mm) and larger, and a wall thickness of 1/4 inch (6 mm) and larger. However, other sizes are available provided all other requirements are met. ASTM A671 pipes are resistant to low temperatures and high pressure, making them particularly useful in conditions requiring resistance to extremely low or humid environments.

- ASTM A672 Standard

The ASTM A672 standard is mainly intended for electric fusion-welded steel pipes used in medium-temperature and high-pressure conditions. A672 pipes are made from high-quality sheet metal and are designed for transporting fluids at high temperatures and pressures. They are suitable for use in medium-temperature (200–350 °C) and high-pressure environments and meet the strict performance requirements for pipelines operating under such conditions. A672 pipes are widely used in high-temperature and high-pressure fluid transportation systems, such as steam pipelines in power plants.

Steel Classification and Standards (ASTM A671 VS ASTM A672) for Raw Material Steel Sheets

| ASTM A671 EFW Pipes Plate Specification | |||

| Pipe Grade | Type of Steel | ASTM Specification | |

| No. | Grade | ||

| ASTM A671 CA 55 Pipe | plain carbon | A285 / A285M | C |

| ASTM A671 CB 60 Pipe | plain carbon, killed | A515 / A515M | 60 |

| ASTM A671 CB 65 Pipe | plain carbon, killed | A515 / A515M | 65 |

| ASTM A671 CB 70 Pipe | plain carbon, killed | A515 / A515M | 70 |

| ASTM A671 CC 60 Pipe | plain carbon, killed, fine grain | A516 / A516M | 60 |

| ASTM A671 CC 65 Pipe | plain carbon, killed, fine grain | A516 / A516M | 65 |

| ASTM A671 CC 70 Pipe | plain carbon, killed, fine grain | A516 / A516M | 70 |

| ASTM A671 CD 70 Pipe | manganese-silicon, normalized | A537 / A537M | 1 |

| ASTM A671 CD 80 Pipe | manganese-silicon, quenced and tempered | A537 / A537M | 2 |

| ASTM A671 CE 55 Pipe | plain carbon | A442 / A442M | 55 |

| ASTM A671 CE 60 Pipe | plain carbon | A442 / A442M | 60 |

| ASTM A671 CF 65 Pipe | nickel steel | A203 / A203M | A |

| ASTM A671 CF 70 Pipe | nickel steel | A203 / A203M | B |

| ASTM A671 CF 66 Pipe | nickel steel | A203 / A203M | D |

| ASTM A671 CF 71 Pipe | nickel steel | A203 / A203M | E |

| ASTM A671 CG 100 Pipe | 9% nickel | A353 / A353M | |

| ASTM A671 CH 100 Pipe | 9% nickel | A553 / A53M | 1 |

| ASTM A671 CJ 101 Pipe | Alloy Steel , quenced and tempered | A517 / A517M | A |

| ASTM A671 CJ 102 Pipe | Alloy Steel , quenced and tempered | A517 / A517M | B |

| ASTM A671 CJ 103 Pipe | Alloy Steel , quenced and tempered | A517 / A517M | C |

| ASTM A671 CJ 104 Pipe | Alloy Steel , quenced and tempered | A517 / A517M | D |

| ASTM A671 CJ 105 Pipe | Alloy Steel , quenced and tempered | A517 / A517M | E |

| ASTM A671 CJ 106 Pipe | Alloy Steel , quenced and tempered | A517 / A517M | F |

| ASTM A671 CJ 107 Pipe | Alloy Steel , quenced and tempered | A517 / A517M | G |

| ASTM A671 CJ 108 Pipe | Alloy Steel , quenced and tempered | A517 / A517M | H |

| ASTM A671 CJ 109 Pipe | Alloy Steel , quenced and tempered | A517 / A517M | J |

| ASTM A671 CJ 110 Pipe | Alloy Steel , quenced and tempered | A517 / A517M | K |

| ASTM A671 CJ 111 Pipe | Alloy Steel , quenced and tempered | A517 / A517M | L |

| ASTM A671 CJ 112 Pipe | Alloy Steel , quenced and tempered | A517 / A517M | M |

| ASTM A671 CJ 113 Pipe | Alloy Steel , quenced and tempered | A517 / A517M | P |

| ASTM A671 CK 75 Pipe | carbon-manganese-silicon | A299 / A299M | |

| ASTM A671 CP 65 Pipe | Alloy Steel , age hardening, normalized and preciotation heat treated | A736 / A736M | 2 |

| ASTM A671 CP 75 Pipe | Alloy Steel , age hardening, quenched and preciotation heat treated | A736 / A736 | 3 |

| ASTM A672 EFW Pipes Plate Specification | |||

| Pipe Grade | Type of Steel | ASTM Specification | |

| No | Grade | ||

| ASTM A672 Grade A45 Pipe | plain carbon | A285 / A285M | A |

| ASTM A672 Grade A50 Pipe | plain carbon | A285 / A285M | B |

| ASTM A672 Grade A55 Pipe | plain carbon | A285 / A285M | C |

| ASTM A672 Grade B55 Pipe | plain carbon, killed | A515 / A515M | 55 |

| ASTM A672 Grade B60 Pipe | plain carbon, killed | A515 / A515M | 60 |

| ASTM A672 Grade B65 Pipe | plain carbon, killed | A515 / A515M | 65 |

| ASTM A672 Grade B70 Pipe | plain carbon, killed | A515 / A515M | 70 |

| ASTM A672 Grade C55 Pipe | plain carbon, killed, fine grain | A516 / A516M | 55 |

| ASTM A672 Grade C60 Pipe | plain carbon, killed, fine grain | A516 / A516M | 60 |

| ASTM A672 Grade C65 Pipe | plain carbon, killed, fine grain | A516 / A516M | 65 |

| ASTM A672 Grade C70 Pipe | plain carbon, killed, fine grain | A516 / A516M | 70 |

| ASTM A672 Grade D70 Pipe | manganese-silicon-normalized | A537 / A537M | 1 |

| ASTM A672 Grade D80 Pipe | manganese-silicon-Q&T | A537 / A537M | 2 |

| ASTM A672 Grade E55 Pipe | plain carbon | A442 / A442M | 55 |

| ASTM A672 Grade E60 Pipe | plain carbon | A442 / A442M | 60 |

| ASTM A672 Grade H75 Pipe | manganese-molybdenum-normalized | A302 / A302M | A |

| ASTM A672 Grade H80 Pipe | manganese-molybdenum-normalized | A302 / A302M | B, C or D |

| ASTM A672 Grade J80 Pipe | manganese-molybdenum-Q&T | A533 / A533M | CI-1 |

| ASTM A672 Grade J90 Pipe | manganese-molybdenum-Q&T | A533 / A533M | CI-2 |

| ASTM A672 Grade J100 Pipe | manganese-molybdenum-Q&T | A533 / A533M | CI-3 |

| ASTM A672 Grade K75 Pipe | chromium-manganese-silicon | A202 / A202M | A |

| ASTM A672 Grade K85 Pipe | chromium-manganese-silicon | A202 / A202M | B |

| ASTM A672 Grade L65 Pipe | molybdenum | A204 / A204M | A |

| ASTM A672 Grade L70 Pipe | molybdenum | A204 / A204M | B |

| ASTM A672 Grade L75 Pipe | molybdenum | A204 / A204M | C |

| ASTM A672 Grade N75 Pipe | manganese-silicon | A299 / A299M | .. |

- ASTM A671 Steel Grade System and Raw Materials

Steel grades conforming to the ASTM A671 standard are represented by a combination of grade and class. The grade indicates the type of sheet, while the class reflects the heat treatment, weld inspection, and pressure testing during the pipeline production process. The raw material sheets mainly used are ASTM A516 (carbon steel sheets for pressure vessels), ASTM A285 (low and medium strength carbon steel sheets for pressure vessels), ASTM A299 (high-strength carbon-manganese-silicon steel sheets for pressure vessels), and ASTM A537 (heat-treated carbon-manganese steel sheets for pressure vessels):

- Low-temperature basic steel grades such as A671CC60, A671GRCC60, and ASTM A671CC60 are manufactured based on A285GR.C steel sheets with a carbon content of ≤0.25%. Low-temperature toughness is enhanced by adding trace nickel elements (0.3–0.6%), making them suitable for low-temperature and high-pressure environments around -30 °C.

- High-toughness steels such as ASTM A671 CC65, A671 CC65 Cl22, and ASTM A671 CC65 Cl22 are produced from A537 Cl.2 steel sheets after normalization. They have a phosphorus and sulfur content of ≤0.03%, with 100% radiographic inspection of welds. The impact energy at a low temperature of -45 ℃ is ≥34 J, making them suitable for ultra-low-temperature conditions (e.g., for LNG transportation).

- The high-strength steel grade A671CC70, manufactured based on A299 steel sheets, has a yield strength of over 480 MPa and good low-temperature toughness. It is suitable for situations requiring resistance to extremely high external pressure at low temperatures (e.g., pipelines for cryogenic equipment).

- Ordinary low-temperature steel grades also include derivative models based on A516 Gr.60 steel, which are suitable for ordinary low-temperature high-pressure pipelines at -29 °C and have better economic efficiency than nickel-containing steel grades.

- ASTM A672 Steel Grade System and Raw Materials

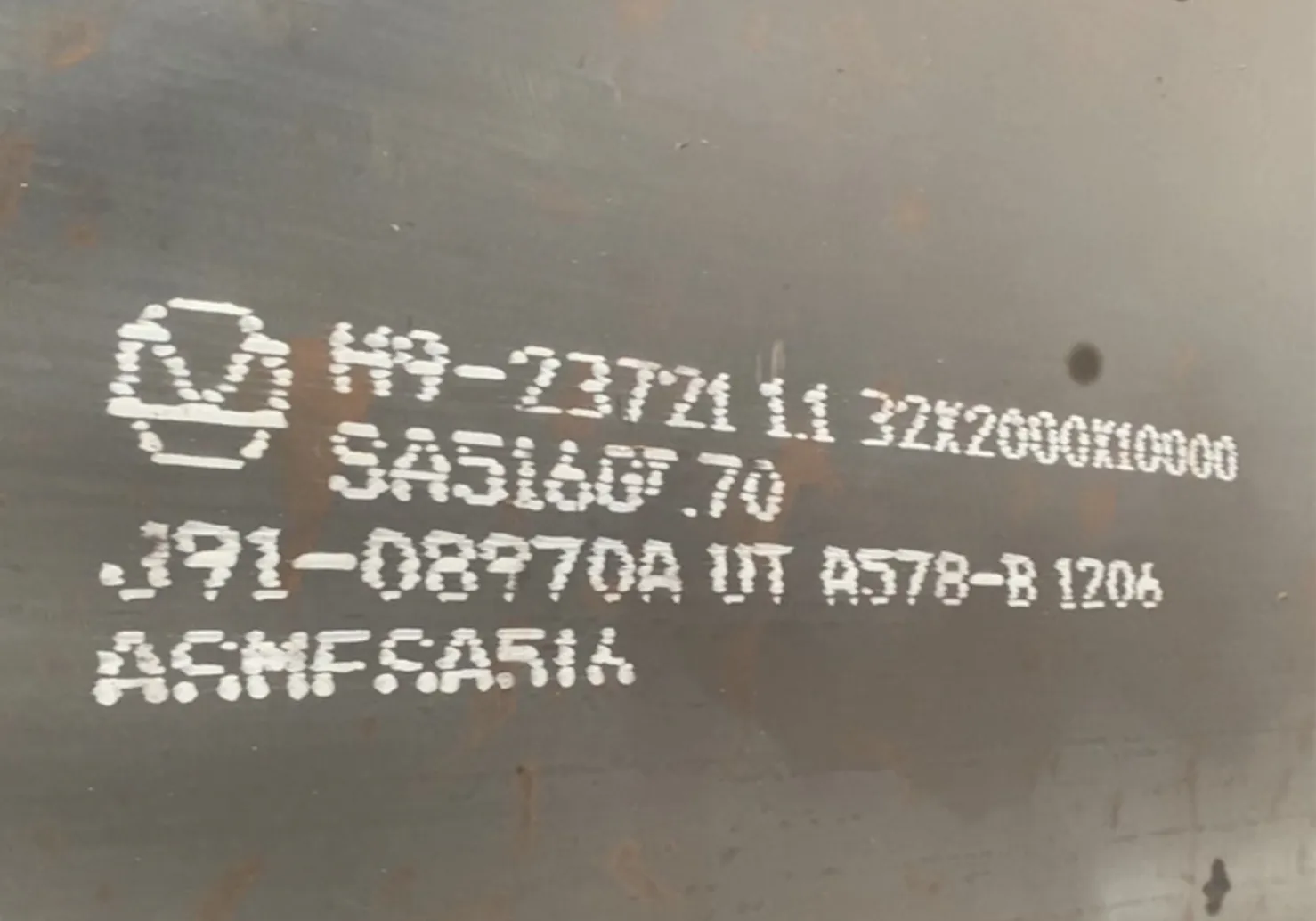

Steel grades under the ASTM A672 standard are designated as “material + grade”. The raw materials mainly used are ASTM A285 (low and medium strength carbon steel sheets for pressure vessels), ASTM A515 (carbon steel sheets for medium-temperature pressure vessels), ASTM A516 (carbon steel sheets for pressure vessels), and ASTM A537 (heat-treated carbon-manganese steel sheets for pressure vessels):

- Basic steel grades such as A672 B60, A672 GRB60, and ASTM A672 GRB60 are made from A515 Gr.60 steel sheets with a carbon content of ≤0.27%, a manganese content of 1.0%-1.3%, and a tensile strength of 485-620 MPa. They are suitable for medium-temperature and high-pressure pipelines at 200-300 ℃.

- Heat-resistant steels such as A672 C60 CL22, ASTM A672 C65 CL22, and A672 C65 CL22 are manufactured from A516 Gr.70 steel sheets after normalization (CL22). Their heat resistance is improved by optimizing the manganese-silicon ratio, making them suitable for high-temperature and high-pressure environments above 300 °C (e.g., for steam pipelines in power plants).

- Ultra-high-pressure steels such as A672C70 and ASTM A672GRC60 are produced based on A537Cl.1 steel sheets. After quenching and tempering, their yield strength reaches over 450 MPa, and the strength retention at 400 °C exceeds 80%. They are suitable for ultra-high-pressure pipeline systems.

- A285 Gr.B steel sheets are used as an economical steel grade, suitable for medium-temperature (≤250 ℃) and low-pressure conditions, with a cost 10–15% lower than that of the A515 serie

Comparison of Performance Differences (ASTM A671 VS ASTM A672)

Essentially, the differences in performance between them are due to differences in alloy composition and heat treatment processes, specifically:

- Weldability and Mechanical Properties

- ASTM A671: Tensile strength is approximately 485–620 MPa, and yield strength is approximately 345–415 MPa. All steel types (e.g., A671 Gr CC60 and A671 CBD60) require good weldability and can be welded by arc welding, gas shielded welding, and other methods. No complex heat treatment is required after welding to maintain low-temperature toughness.

- ASTM A672: The tensile strength (550–700 MPa) and yield strength (380–480 MPa) of A672 grade pipes (e.g., A672 B60 and ASTM A672) are significantly higher than those of A671. Preheating (150–200 °C) and post-weld stress relief treatment are required to prevent cracking and adapt to mechanical loads under high pressure and temperature.

- High Temperature Resistance and Corrosion Resistance

- ASTM A671: Models such as ASTM A671 CC60 and A671 CC65 Cl22 control phosphorus and sulfur content (≤0.03%) and add nickel. The Charpy impact energy at -45 ℃ is ≥27 J, with excellent weather resistance. They can be used for a long time in harsh cold and humid conditions (e.g., pipelines in northern oil fields).

- ASTM A672 models: A672 C60 Cl22, ASTM A672 Gr C60, and others improve high-temperature stability through alloying with chromium and molybdenum. The strength retention rate at 350 ℃ is more than 85%, but the resistance to low-temperature corrosion is relatively weak, making them suitable for dry high-temperature environments (e.g., high-temperature steam pipelines in chemical plants).

Application Fields and Recent Key Projects

- ASTM A671 Standard: Steel Applications and Projects

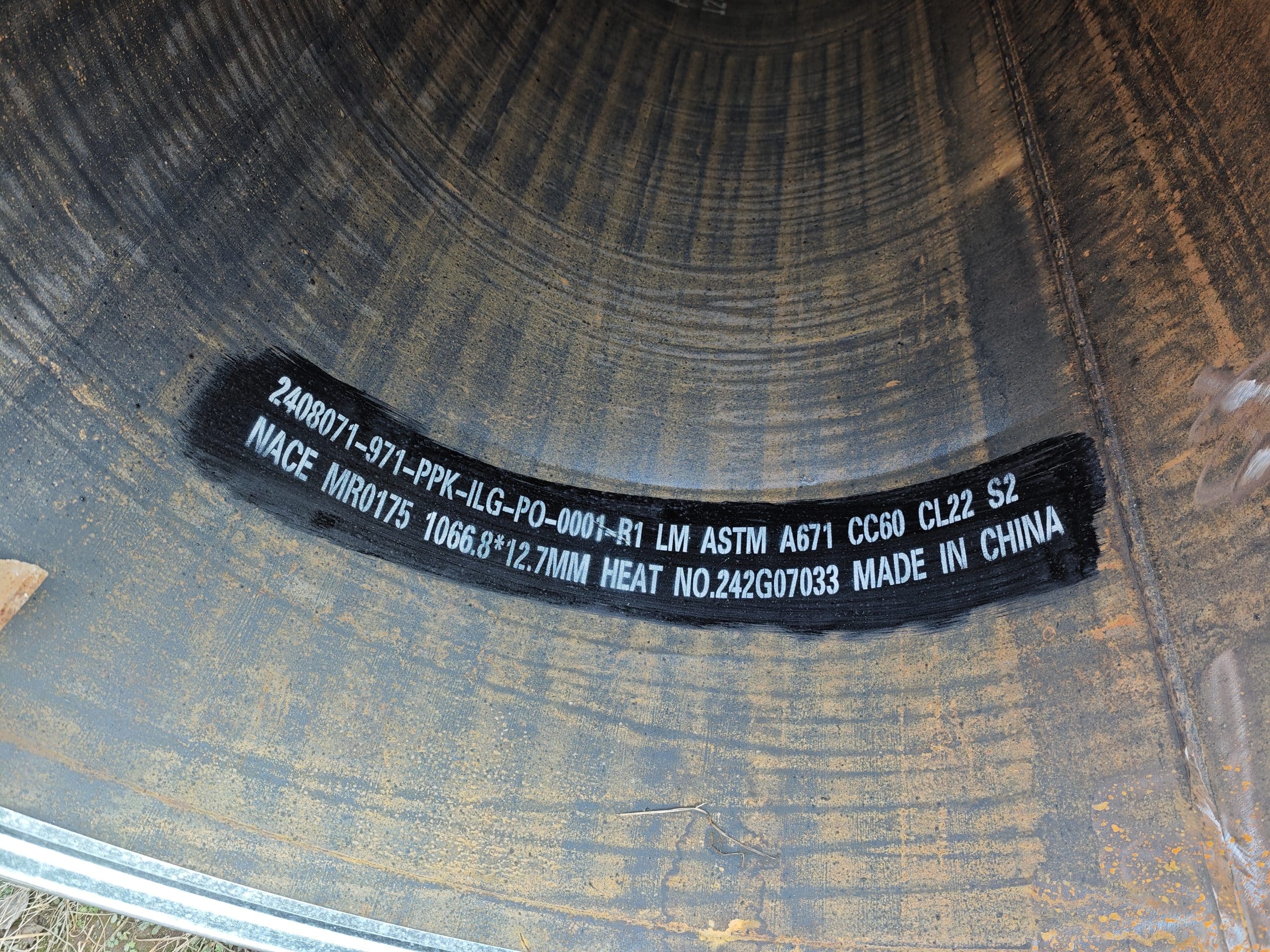

- Energy sector: The northern section of the China-Russia Eastern Route Gas Pipeline (scheduled for commissioning in 2023) uses ASTM A671 pipes (e.g., A671 CC60). This section passes through cold regions such as Heilongjiang and Inner Mongolia, where the minimum temperature reaches -40 °C. The pipeline uses A671 CC65 Cl22 steel grade, which ensures the safety of natural gas transportation in winter due to its excellent low-temperature toughness.

- Chemical industry: The LNG storage tank project in Xinjiang (scheduled for completion in 2024) uses A671CC65CL22 as the connecting pipeline between the storage tank and the transfer pump, enabling operation at ultra-low temperatures with zero leakage at -162 °C.

- Municipal engineering: The heating pipes used in the Beijing Winter Olympics (commissioned in 2022) are made of A671GRCC60 material, which did not crack in extreme weather conditions at -25 °C, ensuring stable heating in the venues.

- ASTM A672 Standard: Steel Applications and Projects

- Energy sector: At the Thar Coal Power Plant in Pakistan (power generation in 2023), ASTM A672 GR B60 steel is used as the high-temperature steam pipeline (380 °C, 12 MPa) of the boiler, which has withstood long-term testing in high-temperature desert conditions.

- Chemical industry: The 40 million tons/year refining and chemical integration project of Zhejiang Petrochemical (scheduled for commissioning in 2024) uses A672C65CL22 steel as the high-pressure reaction feed pipeline (320 °C, 18 MPa) of the hydrocracking unit to meet the corrosion resistance requirements under high temperature and pressure conditions.

- Oil and gas extraction: The pipeline of the Jubail gas field in Saudi Arabia (scheduled for completion in 2023) uses ASTM A672 C70 oil pipeline for deep-water laying (260 °C, 22 MPa), which can adapt to extremely high temperature and pressure conditions in the desert.

The ASTM A671 series (e.g., A671 CC60, ASTM A671 CC65) is characterized by low-temperature strength and corrosion resistance. The sheet steel used as raw material is designed for low-temperature operation and is suitable for high-pressure pipelines in low-temperature and high-humidity conditions. The ASTM A672 series (e.g., A672 B60, ASTM A672 GRC60) is characterized by high-temperature resistance and strength. The raw material used is heat-resistant alloy sheet steel, suitable for operation in medium, high-temperature, and high-pressure conditions.

The choice should be made according to the actual operating conditions: ASTM A671 is preferred for low-temperature and humid conditions, while ASTM A672 is preferred for high-temperature, high-pressure, and dry conditions. From the perspective of recent key projects, both materials play an irreplaceable role in key projects in the energy, chemical industry, etc., and their differences in performance also determine the scope of their application.

LONGMA produces and stocks a full range of ASTM A671 & ASTM A672 EFW steel pipes. It can be welded or seamless heavy wall steel pipes for machine work. We export tens of thousands of tons of such steel pipes every year to EU, UK, Thailand, Singapore, Austrilia, New Zealand, Iran, Peru, Chile. If you want to import high quality ASTM A671 CC60 CC65 CC70, ASTM A672 C60 C65 C70 EFW/LSAW steel pipes, come to LONGMA.

- Grade: CA55, CB60, CB65, CB70, CC60, CC65, CC70

- Class: 10, 11, 12, 20, 22, 50, 60, 70

- Out Diameter: 406.4-1422mm(16″-56″)

- Wall Thickness: 7.92-50.8mm(0.312″ – 2″)

- Length: 3-12.5 meters

Email: info@ilongma.com

Reference:

Artical:

Standard: