In critical infrastructure projects like wind turbine towers and cross-sea bridges, conventional steel pipes often face construction delays due to insufficient strength or low-temperature brittleness. However, EN 10219-compliant S355J2H high-strength structural pipes are emerging as the industry’s new favorite – boasting not only an exceptional 355MPa yield strength but also remarkable -20°C impact resistance. Their superior weldability can reduce construction time by over 30%. With the rapid development of renewable energy infrastructure, these high-strength, high-toughness pipes are redefining industry standards… This article provides an in-depth analysis of EN 10219 S355J2H steel pipes’ performance advantages and explores how they’re driving innovation and industrial advancement in high-strength structural tubing technology.

Definition and Standard Origin of S355J2H Steel Pipes

1. Basic Definition

S355J2H is a high-strength fine-grained structural steel compliant with European standards, specifically designed for cold-formed welded hollow sections (such as round, square, and rectangular tubes). Its naming convention is interpreted as follows:

“S355”: Indicates a minimum yield strength of 355 MPa, classifying it as medium-high-strength structural steel.

“J2”: Represents the material’s impact toughness grade, requiring Charpy V-notch impact energy ≥27J at -20°C (longitudinal test) to ensure resistance to brittle fracture in low-temperature environments.

“H”: Stands for “Hollow Section,” denoting that the steel is specifically used for manufacturing cold-formed welded steel pipes or hollow structural components.

This type of steel pipe combines high strength, excellent weldability, and low-temperature toughness, making it widely applicable in construction, bridges, mechanical engineering, and other fields—particularly for projects demanding lightweight design and structural stability.

2. Standard Origin: EN 10219

The material and manufacturing specifications for S355J2H are strictly defined by the European Standard EN 10219, with the full title:

EN 10219-1:2006

“Cold-formed welded structural hollow sections of non-alloy and fine grain steels – Part 1: Technical delivery conditions”

Key requirements include:

Material properties: Chemical composition (content of C, Si, Mn, etc.), mechanical properties (yield strength, tensile strength, elongation, etc.).

Process specifications: Cold-forming and high-frequency welding (HFW) techniques.

Testing standards: Non-destructive testing (e.g., ultrasonic), impact tests, bending tests, etc.

3. Relationship with Other Standards

Comparison with EN 10210: EN 10219 applies to cold-formed welded tubes, while EN 10210 covers hot-finished seamless or welded tubes, resulting in differences in processes and performance.

International equivalents: Such as China’s GB/T 6728 (cold-formed hollow structural sections) and the U.S. ASTM A500. However, S355J2H offers superior performance due to its strict fine-grained structure and low-temperature toughness requirements.

4. Core Advantages in Industrial Applications

Lightweight design: High strength allows for reduced material usage and lower structural weight.

Ease of welding: Low carbon equivalent (CEV) minimizes welding crack risks.

Environmental adaptability: -20°C impact toughness ensures safety in cold-region engineering.

Chemical Composition and Mechanical Properties of S355J2H Steel Pipe

1. Chemical Composition of S355J2H

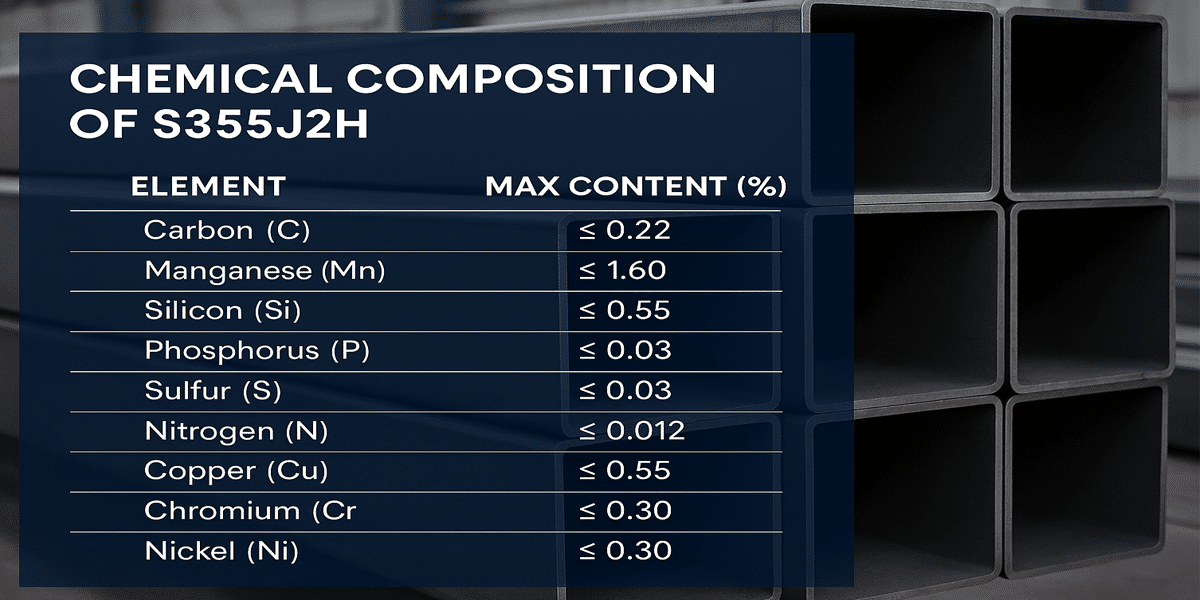

According to the EN 10219-1 standard, S355J2H is a non-alloy structural steel designed for hollow section applications. Its chemical composition is carefully balanced to provide excellent weldability, strength, and toughness. Below is the typical range (in % by weight):

Note: The low carbon content enhances the weldability of S355J2H, making it ideal for large-scale welded structures without compromising strength or toughness.

2. Mechanical Properties of S355J2H

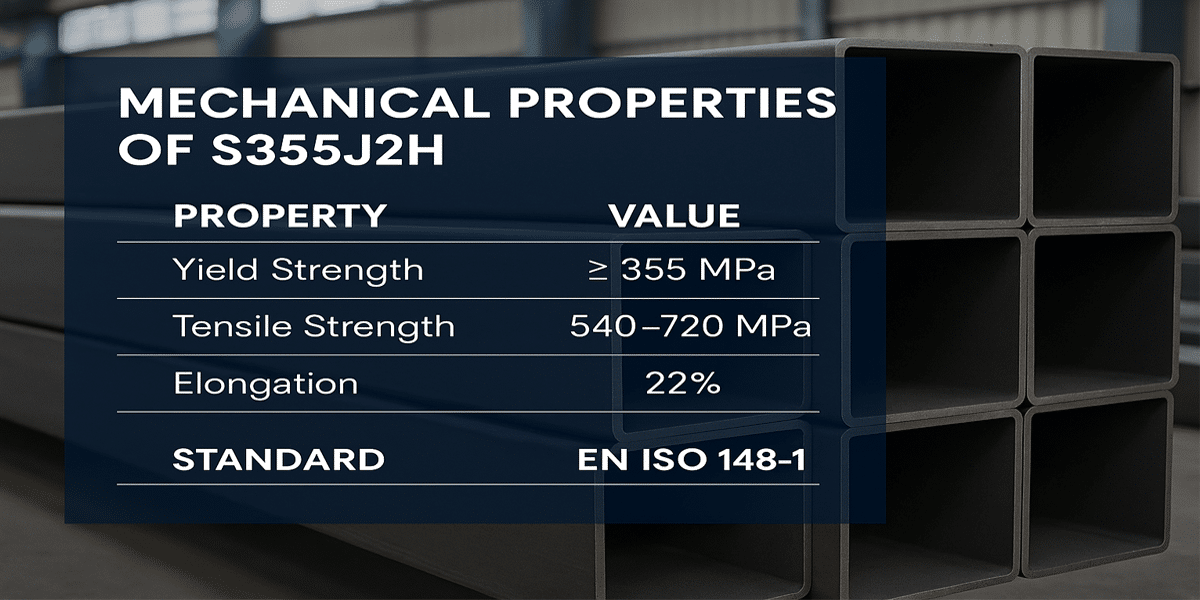

As a typical high-strength structural tube, EN 10219 S355J2H exhibits excellent mechanical performance. Its properties make it suitable for demanding structural and engineering applications:

The J2 designation guarantees excellent impact toughness at -20°C, which is critical for structural applications in cold climates or safety-critical environments.

3. Performance Advantages

High Strength-to-Weight Ratio: Enables lighter structures without compromising stability.

Excellent Weldability: Thanks to low carbon and well-balanced alloying elements.

Reliable Toughness: Ensures structural integrity under low-temperature conditions.

Fully Compliant with EN 10219: Offers quality assurance for structural engineers and fabricators.

Comparison of S355J2H and S235JRH Steel Grades

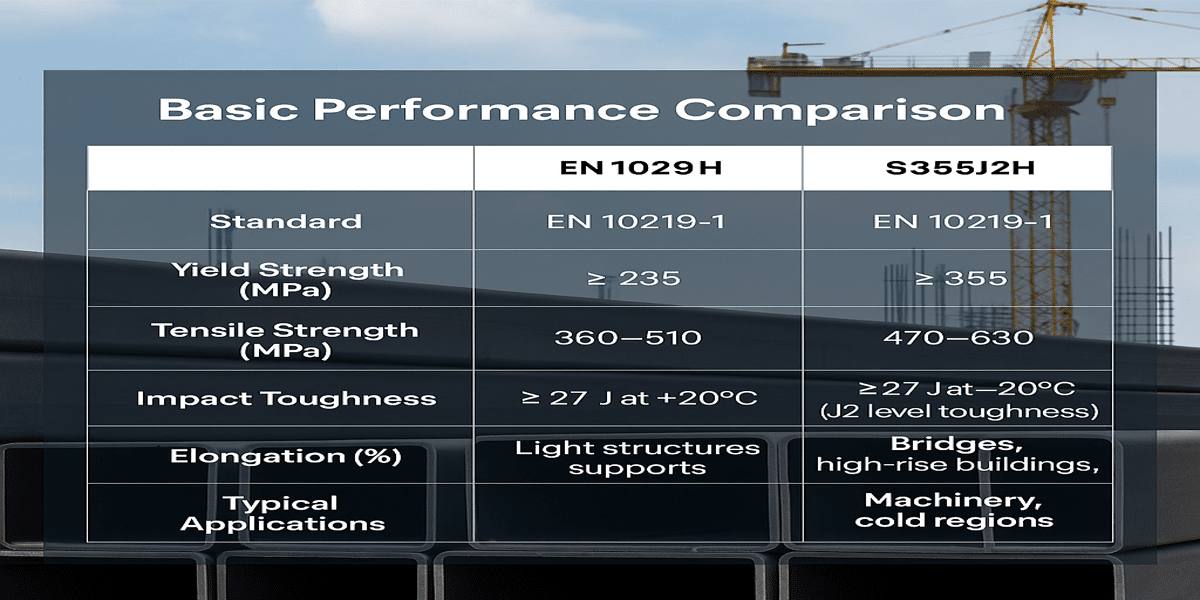

When selecting structural hollow sections for construction or engineering applications, designers often choose between several steel grades defined under the EN 10219 standard. Two commonly used grades are S235JRH and S355J2H. While both are non-alloy structural steels, they differ significantly in strength, toughness, and application suitability.

Key Advantages of S355J2H

✅ 1. Higher Strength

S355J2H offers around 50% higher yield strength compared to S235JRH, making it ideal for load-bearing structures.

This increased strength allows engineers to reduce section size and weight without sacrificing performance, improving both cost-efficiency and structural design.

✅ 2. Superior Low-Temperature Toughness

While S235JRH only guarantees impact energy at room temperature (20°C), S355J2H is tested at –20°C, offering enhanced safety for cold climates, bridges, and offshore structures.

✅ 3. Wider Application Range

As a high-strength structural tube, EN 10219 S355J2H is widely used in high-rise buildings, cranes, wind towers, and mechanical structures.

In contrast, S235JRH is more commonly used in lighter-duty applications like secondary supports or low-load structures.

✅ 4. Design Flexibility

With its higher strength-to-weight ratio, S355J2H enables more compact and efficient designs, ideal for modern architecture and industrial applications.

Typical Applications of S355J2H Steel Pip

As a non-alloy structural steel conforming to EN 10219, S355J2H is widely recognized for its high strength, excellent toughness, superior weldability, and low-temperature performance. These characteristics make it a preferred material in many industries requiring safe, durable, and high-load-bearing steel components.

1. Building Structures & High-Rise Steel Frames

Applications: Columns, beams, bracing systems, trusses, and structural frames.

Advantages:

High yield strength (≥355 MPa) ensures structural reliability.

Enables slimmer structural members, increasing usable space.

Ideal for sustainable and material-efficient design.

In modern high-rise construction, S355J2H high-strength structural tube offers excellent performance with reduced steel weight and enhanced structural integrity.

2. Bridge Engineering & Civil Infrastructure

Applications: Bridge piers, cross beams, tension members, guardrail supports.

Advantages:

Superior low-temperature toughness (tested at –20°C) fits cold-weather projects.

High strength allows for long spans and reduced structural mass.

Many modern steel bridges utilize EN 10219 S355J2H tubes for critical load-bearing components due to their combination of strength and ductility.

3. Heavy Machinery & Equipment Fabrication

Applications: Crane arms, mechanical frames, container chassis, industrial supports.

Advantages:

High mechanical strength for dynamic loads.

Excellent weldability for complex fabrication requirements.

In equipment like cranes and excavators, S355J2H tubes help ensure both structural safety and long service life under heavy use.

4. Wind Energy & Renewable Power Systems

Applications: Wind turbine towers, internal support structures, solar panel frames.

Advantages:

Great fatigue resistance under cyclic loading.

Durable even in offshore or high-wind environments.

In the renewable energy sector, S355J2H high-strength structural tubes are key to supporting tall, slender, and highly durable wind towers.

5. Petrochemical & Industrial Piping Systems

Applications: Pipe racks, structural platforms, equipment support frames.

Advantages:

Compatible with protective coatings like galvanizing or painting.

Maintains integrity in outdoor, corrosive, or high-temperature settings.

6. Transportation Hubs & Public Facilities

Applications: Subway stations, airport terminals, pedestrian bridges, canopy structures.

Advantages:

Aesthetic profiles with customizable cross-sections.

Easy to weld and fabricate for complex architectural needs.

Technical Recommendations for Using S355J2H Steel Pipes

S355J2H, defined under the EN 10219 standard, is a high-strength structural steel pipe widely used in demanding applications such as building construction, bridges, wind energy, and heavy machinery. To fully utilize the advantages of this material, engineers should follow specific technical best practices during selection, design, and processing stages.

1. Material Specification & Certification

Applicable Standard: EN 10219-1/2 for cold-formed hollow structural sections.

Designation Meaning: S355: Minimum yield strength of 355 MPa. J2: Impact tested at –20°C. H: Hollow section intended for structural applications.

Checklist Before Use:

Verify material test certificate (MTC): EN 10204 3.1 or 3.2.

Ensure compliance with chemical composition and mechanical properties.

Confirm J2-level impact toughness for cold climate applications.

Always perform a material compliance check before installation to ensure that the EN 10219 S355J2H steel pipe batch meets design and regulatory requirements.

2. Structural Design Considerations

Design Strength: Use ≥355 MPa yield strength in structural calculations to optimize load-bearing capacity.

Cross-Section Selection: Choose round, square, or rectangular profiles based on structural efficiency and design aesthetics.

Wall Thickness Selection:

Thicker walls are recommended for fatigue-prone or dynamically loaded structures.

Connection Type:

Welding is preferred for structural integrity; bolting or sleeve joints may be used where appropriate.

S355J2H high-strength structural tube enables efficient, lightweight designs in modern construction and industrial structures.

3. Welding Recommendations

Weldability: S355J2H offers excellent weldability due to its low carbon equivalent.

Best Practices:

Preheating is usually not required for thicknesses under 40mm, unless ambient temperature is very low.

Use low-hydrogen electrodes to prevent cold cracking.

Apply multi-pass welding for thicker walls, ensuring proper inter-pass temperature control.

Post-Weld Treatment: Not typically required, but stress-relief heat treatment may be applied for high-stress or fatigue-critical structures.

4. Forming & Cutting Techniques

Cold Bending:

S355J2H can be cold-formed, but higher forming forces and larger bend radii are required compared to lower-grade steels.

Cutting Recommendations:

Use plasma or laser cutting for precise and clean edges.

Always grind and deburr cut edges, especially before welding, to avoid crack initiation.

Trial cuts or bend tests are advised before large-scale fabrication to optimize parameters.

5. Corrosion Protection & Surface Treatment

Corrosion Resistance: S355J2H is not inherently corrosion-resistant.

For outdoor use, apply hot-dip galvanizing, epoxy coatings, or polyurethane paint systems.

In marine or aggressive environments, use multi-layer protective coatings.

Surface Preparation: Ensure Sa2.5 blasting or equivalent before painting for proper adhesion.

6. Environmental Application Guidelines

Cold climates: Use J2-rated pipes to ensure safe impact performance at –20°C

Humid or marine areas: Apply advanced corrosion protection (e.g., zinc + epoxy system)

High dynamic loading: Choose thicker walls and perform fatigue analysis

Precision welding zones: Use positioning jigs and proper welding sequences to maintain dimensional accuracy

In summary, S355J2H steel pipe, manufactured under the EN 10219 standard, offers an ideal combination of strength, toughness, and weldability, making it a trusted high-strength structural tube across a wide range of industries. Its excellent performance in both structural and environmental conditions allows engineers and builders to design safer, lighter, and more efficient systems. By selecting certified S355J2H materials and applying proper technical practices, projects can achieve long-term durability and cost-effective results in demanding applications such as buildings, bridges, renewable energy, and heavy equipment!