- 1. Detailed Introduction to EN 10219 Structural Steel Pipes

- 2. Detailed Analysis of the Structural Advantages of EN 10219 Steel Pipes in Construction Projects

- 3. Aesthetic and Spatial Advantages of EN 10219 Steel Pipes in Architecture

- 4. Typical Application Scenarios and Success Cases of EN 10219 Steel Pipes

- 5. Comparative Advantages of EN 10219 Steel Pipes over Other Structural Steel Pipe Standards

- 6. Professional Guide for EN 10219 Steel Pipe Design Selection and Procurement

With the rapid acceleration of urbanization, the construction industry is undergoing unprecedented transformation and opportunity. Green buildings, prefabricated construction, and efficient structural design have become mainstream trends in modern architecture. In this wave of development, EN 10219 steel pipes are widely used in modern building steel structures, thanks to their outstanding performance and standardized manufacturing processes, making them a preferred choice for many structural engineers and designers. As a type of structural hollow section steel, EN 10219 steel pipes offer excellent dimensional control and demonstrate great flexibility during construction, significantly enhancing efficiency and adaptability on site. These multiple advantages have made them a key component in steel structure projects such as high-rise buildings, bridges, industrial plants, and large-scale venues…

Detailed Introduction to EN 10219 Structural Steel Pipes

1. What is EN 10219 Steel Pipe?

EN 10219 is a technical standard issued by the European Committee for Standardization (CEN) for cold-formed welded structural hollow sections, widely used in steel structure design for buildings, bridges, and mechanical engineering. The standard specifies requirements for material composition, dimensional tolerances, mechanical properties, manufacturing processes, and testing methods, ensuring excellent load-bearing capacity, weldability, and construction adaptability.

2. Main Classifications and Specifications

EN 10219 steel pipes are categorized into three types based on cross-sectional shape:

Circular Hollow Sections (CHS)

Square Hollow Sections (SHS)

Rectangular Hollow Sections (RHS)

Typical Size Ranges:

Outer diameter (for round pipes) or side length (for square/rectangular pipes): 20mm ~ 600mm

Wall thickness: 1.0mm ~ 40mm

Length: Typically 6m~12m (customizable)

3. Core Materials and Mechanical Properties

Common steel grades under EN 10219 (e.g., S235JR, S355J2H) must meet strict chemical composition and mechanical property requirements:

Tensile Strength: 340MPa ~ 550MPa (varies by material)

Yield Strength: 235MPa ~ 355MPa

Elongation: ≥22% (ensuring ductility)

Impact Toughness: Maintains good performance even at -20°C (suitable for construction in cold regions).

4. Advantages of Manufacturing Process

EN 10219 pipes are produced using cold-forming + high-frequency welding (HFW), offering key benefits over hot-rolled pipes:

High Dimensional Accuracy: Tight tolerances (e.g., wall thickness deviation ±10%), ideal for precision assembly.

Superior Surface Quality: Free of oxide scale, ready for direct painting or galvanizing.

Lightweight Design: Lighter than hot-rolled sections under equivalent load capacity, reducing structural weight.

5. Industry Applications

Thanks to their performance advantages, EN 10219 pipes are widely used in:

Building Structures: Stadiums, airport terminals, high-rise building frameworks (e.g., modular steel housing).

Bridge Engineering: Truss bridges, pedestrian bridge chords, and web members.

Machinery & Equipment: Crane booms, conveyor supports, etc.

Detailed Analysis of the Structural Advantages of EN 10219 Steel Pipes in Construction Projects

EN 10219 steel pipes, as a crucial material in modern steel structure construction projects, are being widely adopted in various building applications due to their unique structural performance advantages. The following provides a multidimensional analysis of their structural benefits:

1. Superior Mechanical Performance Advantages

High strength-to-weight ratio: Utilizes premium steel grades like S355J2H with yield strength up to 355MPa while maintaining lightweight properties

Uniform stress distribution: Cold-forming process ensures material isotropy, avoiding residual stress issues common in hot-rolling processes

Excellent bending and torsion resistance: Closed-section characteristics provide torsional stiffness over 100 times greater than open sections

2. Construction Convenience Advantages

Modular construction: Standardized dimensions and connection methods support prefabricated assembly

Simplified joint treatment: Allows direct welding, bolted connections, or specialized connectors

Flexible on-site processing: Easy cutting and drilling to accommodate complex joint design requirements

3. Economic Structural Advantages

High material utilization: Precise dimensional control reduces material waste (saving 5-8% steel consumption)

Lower transportation/installation costs: Lightweight properties reduce hoisting and transportation expenses

Superior life-cycle cost: Minimal maintenance requirements with service life exceeding 50 years

4. Seismic and Durability Advantages

Excellent seismic performance: High ductility (elongation ≥22%) effectively absorbs seismic energy

Enhanced fatigue resistance: Welded joint fatigue strength 20-30% higher than conventional steel

Corrosion-resistant design: Compatible with hot-dip galvanizing or special coatings

5. Design Flexibility Advantages

Strong architectural expression: Capable of creating curved and special-shaped structures for unique architectural forms

High space utilization: Hollow structure facilitates utility routing, optimizing usable space

Cross-section optimization: Choice of circular, square or rectangular sections based on load characteristics

6. Sustainable Structural Advantages

Green building certification: 100% recyclable, compliant with LEED and other green building standards

Carbon emission advantage: Reduces carbon footprint by over 40% compared to concrete structures

Low construction pollution: No wet works on site, minimizing construction waste

Aesthetic and Spatial Advantages of EN 10219 Steel Pipes in Architecture

In modern architecture, structures are expected not only to perform but also to look good. As architectural design increasingly emphasizes both structural aesthetics and space optimization, structural elements are no longer hidden behind cladding or walls—they actively shape the building’s visual identity and spatial atmosphere. EN 10219 structural steel pipes are an ideal material to embody this design philosophy, offering distinct advantages in both aesthetics and spatial efficiency due to their unique geometry and structural performance.

1. Clean Lines That Highlight Architectural Geometry

EN 10219 steel pipes are available in circular, square, and rectangular hollow sections. These sleek, well-defined geometric shapes carry a strong sense of modernity and align perfectly with minimalist architectural trends.

Their flexible arrangement—whether in parallel lines, diagonal intersections, or spatial grids—can provide both structural integrity and striking visual rhythm. As a result, EN 10219 pipes are increasingly used not just as functional supports but as aesthetic elements in façades, interior spaces, and even landscape structures.

2. Compact Sections That Maximize Space and Transparency

Compared to open-profile materials like I-beams or channels, EN 10219 hollow sections offer a higher strength-to-weight ratio, enabling the use of smaller sections for the same load-bearing requirements. This frees up usable space and reduces visual obstruction.

In high-rise buildings, commercial interiors, or exhibition spaces, where structural elements often intersect with circulation paths or functional zones, EN 10219 steel pipes create a lighter and more transparent feel, enhancing the sense of openness and improving spatial efficiency.

3. Refined Surface Finishes Enhance Overall Building Quality

With smooth surfaces and precise geometry, EN 10219 steel pipes are suitable for a variety of surface treatments such as painting, hot-dip galvanizing, or weather-resistant coatings. Architects can choose from a range of finishes—matte black, industrial gray, metallic silver, etc.—to either blend with or contrast the overall palette.

In many modern projects, exposed steel pipe structures are intentionally highlighted rather than concealed. Combined with glass, concrete, or timber, these steel elements express structural clarity and material authenticity, reinforcing the visual language of the building.

4. Versatility Across Building Types: Merging Structure with Aesthetics

From lightweight truss roofs in office towers to transparent atriums in commercial complexes and observation walkways in tourism architecture, EN 10219 steel pipes adapt seamlessly to a wide range of applications. Their design flexibility and compatibility with different connections empower architects to pursue bold, expressive forms without compromising structural integrity.

Whether used as primary supports or secondary accents, these pipes allow structural expression to become part of the architectural identity.

Typical Application Scenarios and Success Cases of EN 10219 Steel Pipes

I. Typical Application Scenarios

Long-span Spatial Structures

Stadiums and arenas: Space frames, dome structures

Convention centers: Column-free exhibition spaces

Transportation hubs: Airport terminals, high-speed railway station canopies

High-rise Buildings

Super high-rise exterior frame structures

Core tube support systems

Skybridge structures

Special-shaped Architectural Structures

Free-form curved buildings

Parametric facade support structures

Cantilever structural systems

Industrial and Commercial Buildings

Modern factory buildings

Logistics and warehousing centers

Commercial complexes

Bridge Engineering

Pedestrian bridges

Landscape bridges

Temporary construction bridges

II. Internationally Renowned Success Cases

London Olympic Stadium

Application: Lightweight roof structure using EN 10219 steel pipes

Advantage: Achieved significant weight reduction of 55,000 tons of steel

Result: Created the iconic bowl-shaped design

Tour First, Paris

Application: Exterior frame structure for super high-rise

Advantage: Improved seismic performance while optimizing usable space

Result: Became one of Europe’s tallest office towers

Allianz Arena, Munich

Application: ETFE cushion support structure

Advantage: Perfectly met curved design requirements

Result: Achieved stunning nighttime lighting effects

Comparative Advantages of EN 10219 Steel Pipes over Other Structural Steel Pipe Standards

In structural steel construction, selecting the right steel pipe standard is crucial to achieving optimal performance, cost efficiency, and construction quality. EN 10219 cold-formed welded structural hollow sections stand out for their precise dimensions, consistent performance, and wide applicability. Below is a detailed comparison between EN 10219 and other commonly used standards such as EN 10210, ASTM A500, and GB/T 6728, focusing on their technical and practical differences.

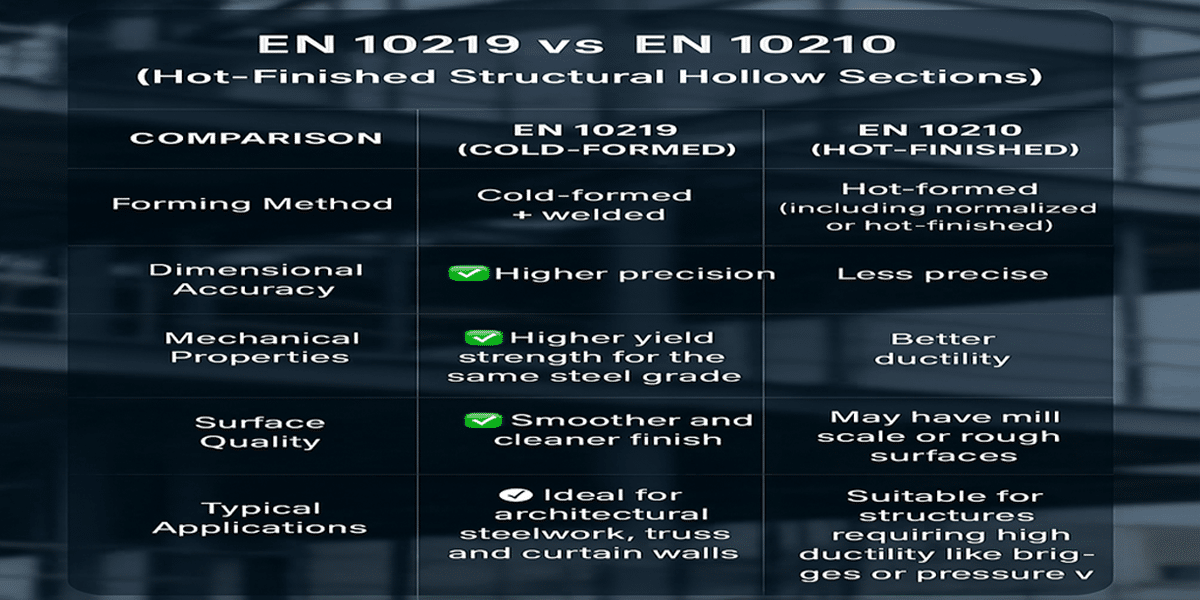

1. EN 10219 vs EN 10210 (Hot-Finished Structural Hollow Sections)

Key Advantage: EN 10219 offers better dimensional control and surface quality, making it highly suitable for visible architectural elements and prefabricated structures.

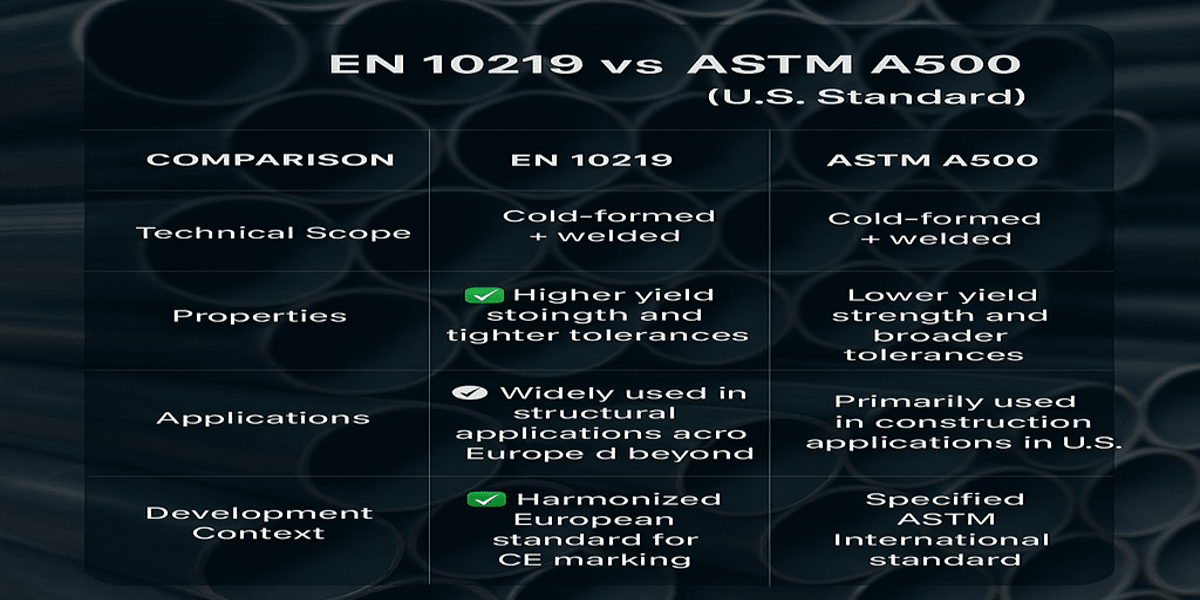

2. EN 10219 vs ASTM A500 (U.S. Standard)

Key Advantage: EN 10219 features more rigorous mechanical and impact performance requirements, especially at low temperatures, making it suitable for international projects and high-performance structures.

Additional Comparative Factors

Low-Temperature Performance: EN 10219 offers grades like S355J2H that remain ductile at –20°C, ideal for cold climates or high-altitude projects.

Sustainability Compatibility: EN 10219 products often meet CE marking and EN 1090-2 requirements, supporting green building certifications like BREEAM and DGNB.

Construction Efficiency: Thanks to its dimensional precision and clean surface, EN 10219 pipes are ideal for BIM modeling, robotic welding, and laser cutting, enabling more efficient prefabrication and digital construction workflows.

Professional Guide for EN 10219 Steel Pipe Design Selection and Procurement

1. Design Selection Recommendations

Select steel grades based on load-bearing requirements

Common grades include S235JRH, S275J0H, and S355J2H. S355J2H offers higher strength and is recommended for large spans, high-rise buildings, or seismic/wind-resistant structures.

For cold climates or high-altitude areas, it is advisable to use grades with certified impact toughness, such as J0H or J2H, to ensure safety at low temperatures.

Prefer structural hollow sections (SHS/RHS)

Compared to open sections, EN 10219 square and rectangular hollow sections offer better torsional resistance, compact size, and cleaner appearance, ideal for modern architectural integration.

Ensure compatibility with fabrication methods

EN 10219 steel pipes are known for excellent dimensional control and fabrication flexibility, making them suitable for precision welding, automated cutting, and modular construction, especially in projects using BIM + off-site prefabrication.

Consider corrosion protection and surface treatment

Plan for hot-dip galvanizing or coating systems during the design stage, especially for exposed components like façades, roofs, or bridges. EN 10219 pipes’ smooth surfaces and uniform thickness support better coating performance.

2. Key Procurement Tips

Ensure full compliance with the EN 10219 standard

Verify compliance with all technical aspects, including dimensional tolerances, mechanical properties, chemical composition, weld quality, non-destructive testing (NDT), and impact test results. For load-bearing structures, request a material certificate according to EN 10204 3.1.

Choose suppliers certified under EN 1090-2

For export projects or any application requiring CE marking, this certification is essential. It also ensures better quality control throughout production.

Verify batch consistency and traceability

Contracts should specify that steel pipes of the same batch must not mix materials from different heats or treatment processes. This ensures uniform performance and avoids installation issues caused by variation.

Evaluate total lifecycle cost—not just price per ton

While EN 10219 steel pipes may have a higher unit price than general welded pipes, their high precision, reduced wastage, and ease of installation can significantly lower overall construction costs—especially in large-scale, complex, or time-sensitive projects.

Additional Advice

Coordinate early with structural designers and contractors to ensure compatibility between design specifications and construction methods.

For visible applications such as curtain walls, skylights, or façade frameworks, prioritize pipes with smooth surfaces and minimal weld marks.

Refer to successful reference projects or case studies in the planning stage; some suppliers can recommend stock-ready specifications to optimize procurement and lead time.

EN 10219 steel pipes have become the material of choice for modern steel structures, thanks to their exceptional performance, precise manufacturing standards, and outstanding sustainability. Whether used in long-span stadiums, skyscrapers, industrial plants, or bridge engineering, they perfectly balance strength, aesthetics, and cost efficiency. For optimal design, match cross-sections to load requirements and enforce strict quality control during procurement. During construction, leverage their modular advantages to maximize efficiency. As digital and low-carbon technologies advance, EN 10219 pipes will unlock even greater potential.

Choose the right standard, apply the right methods—and let every steel pipe become a reliable backbone for architecture!