- 1. What is EN 10219 Steel Pipe?

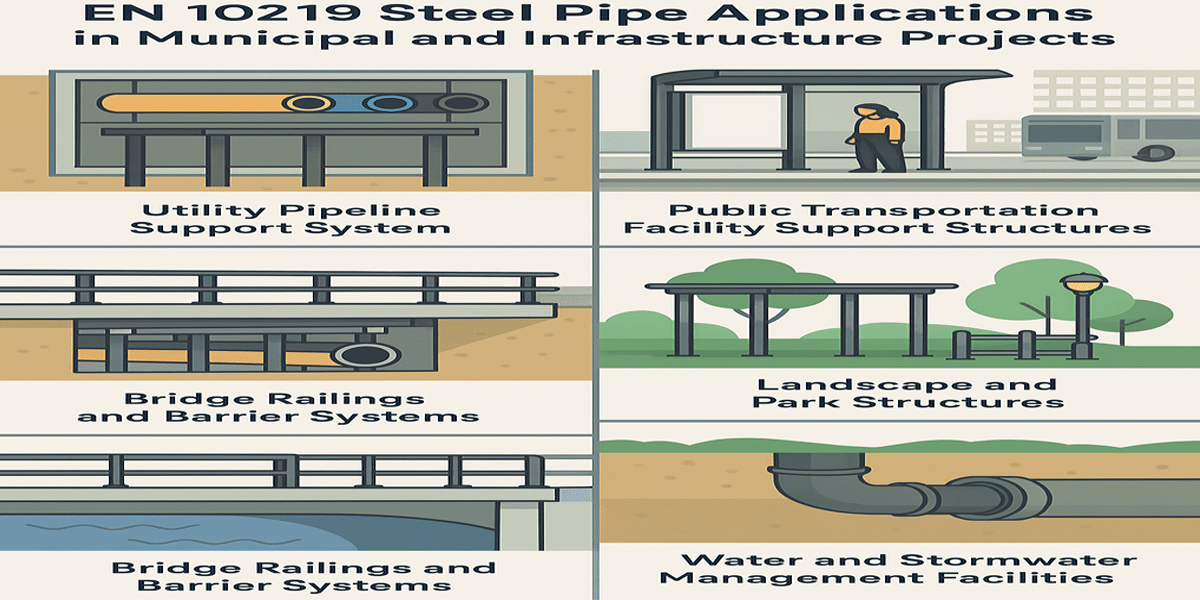

- 2. Application of EN 10219 Steel Pipes in Municipal Pipelines

- 3. Application of EN 10219 Steel Pipes in Transportation Infrastructure

- 4. Application of EN 10219 Steel Pipes in Urban Bridges

- 5. Other Municipal and Infrastructure Applications of EN 10219 Steel Pipes

With the rapid advancement of urbanization, the reliability and safety of municipal pipelines and various infrastructure structural tubes have become critical to ensuring efficient city operations and quality of life for residents. As one of the key standards for structural steel tubes, EN 10219 steel pipes stand out for their excellent mechanical properties, corrosion resistance, and cost-effectiveness, making them widely adopted across numerous engineering sectors. This article explores several EN 10219 engineering cases, offering in-depth insights into their practical value in municipal and infrastructure construction. From urban drainage systems to bridge support structures, and from gas pipelines to rail transit projects, EN 10219 standard steel pipes are increasingly becoming the preferred choice for engineers and construction professionals!

What is EN 10219 Steel Pipe?

EN 10219 is a European standard that specifies requirements for cold-formed welded structural hollow sections of non-alloy and fine grain steels. Issued by the European Committee for Standardization (CEN), it is widely used in building structures, bridges, municipal pipelines, transport infrastructure, and more.

EN 10219 is divided into two parts:

EN 10219-1: Technical delivery conditions

EN 10219-2: Tolerances, dimensions, and sectional properties

Key Features of EN 10219 Steel Pipes

Material Grades

Common grades include S235JRH, S275J2H, and S355J2H, offering various levels of yield strength and impact resistance suitable for a range of structural applications.

Manufacturing Process

EN 10219 pipes are produced using cold forming processes and are typically welded through high-frequency electric resistance welding (ERW). This ensures high dimensional accuracy and uniform wall thickness without the need for heat treatment.

Cross-Section Shapes

Available in circular (CHS), square (SHS), and rectangular (RHS) shapes, these hollow sections are ideal for diverse engineering designs—particularly in infrastructure structural tube applications.

Mechanical Properties

With excellent strength-to-weight ratios, EN 10219 pipes offer strong resistance to bending and compression. They are a key material in many EN 10219 engineering cases, especially where structural load-bearing capacity is critical.

Sustainability and Environmental Benefits

The production of EN 10219 steel pipes involves lower energy consumption and high recyclability, aligning with modern sustainable construction practices.

Typical Applications

EN 10219 steel pipes are widely applied in:

Municipal Projects: Urban drainage, water supply systems, gas pipelines, and other municipal pipeline infrastructures

Infrastructure Construction: Bridge piles, tunnel supports, rail transit systems, utility corridors, and other infrastructure structural tube uses

Building Structures: Industrial buildings, high-rise steel structures, support frameworks

Transportation Facilities: Road barriers, sign poles, and structural components of urban furnishings

Application of EN 10219 Steel Pipes in Municipal Pipelines

With the rapid expansion of urban development, municipal pipeline systems have grown increasingly complex and critical. These systems include water supply, drainage, gas, heating, and cable protection pipelines. To meet the requirements of high strength, corrosion resistance, long service life, and installation efficiency, more and more municipal projects are turning to EN 10219 steel pipes as structural supports or protective casings, playing a vital role in ensuring the safety and stability of urban infrastructure.

1. As Casing and Protective Pipes — Structural Integrity & Construction Efficiency

In water supply, sewer, and utility conduit systems that cross roads, rivers, or other obstacles, EN 10219 steel pipes are often used as external casing pipes to protect the internal pipelines from mechanical damage. Their high strength and standardized dimensions make them especially suitable for trenchless methods like jacking, HDD (horizontal directional drilling), and micro-tunneling. In load-bearing zones, they function as infrastructure structural tubes, capable of withstanding ground pressure and traffic loads.

2. Pipe Supports and Structural Frameworks

Square (SHS) and rectangular (RHS) EN 10219 steel sections are widely used in supports, bracing frames, chamber reinforcements, and related components. These appear frequently in combined sewer systems, gas pressure-regulating stations, pumping stations, and valve chambers. These structures not only bear the load of pipelines and accessories, but also need to resist wind, vibration, and environmental corrosion. The cold-formed precision and uniform performance of EN 10219 steel pipes make them well suited for such demands.

3. Superior Corrosion Resistance and Weatherability

EN 10219 pipes can be treated with internal and external coatings such as hot-dip galvanizing or epoxy powder coating to enhance durability in damp, buried, or chemically aggressive environments. Compared to conventional non-structural steel pipes, they offer extended service life and reduced maintenance, as demonstrated in numerous EN 10219 engineering cases within municipal pipeline systems.

Application of EN 10219 Steel Pipes in Transportation Infrastructure

Transportation infrastructure—such as bridges, elevated highways, tunnels, subways, urban rail systems, and associated structures—forms the backbone of urban development and regional connectivity. These projects demand materials with high strength, fatigue resistance, and structural reliability. EN 10219 steel pipes have become essential in numerous transportation infrastructure projects due to their excellent performance and adaptability.

1. Bridge Structures and Guardrail Systems

In bridge engineering, EN 10219 square (SHS) and rectangular (RHS) hollow sections are commonly used for:

Bridge guardrail posts and rails: Providing strong support to meet anti-collision and wind load requirements

Architectural railings and safety barriers: Offering clean lines, aesthetic appeal, and ease of fabrication

Structural reinforcement and load-bearing frames: Used in pedestrian bridges and lightweight overpasses

Thanks to their standardized cross-sections and dimensional accuracy, EN 10219 pipes are ideal infrastructure structural tubes, and their performance has been verified in numerous EN 10219 engineering cases.

2. Subway and Light Rail Support Systems

In metro and urban transit systems, EN 10219 steel pipes serve various roles:

Tunnel reinforcement structures: Used in sprayed concrete mesh frameworks and anchor systems

Equipment platforms and station-level frameworks: Easy to install with good seismic performance

Cable tray supports in utility corridors: Providing support for municipal pipelines like water, electrical, or communication lines

Cold-formed EN 10219 pipes are highly weldable and easy to assemble with other structural elements, ensuring fast installation and long-term durability.

3. Urban Roadway Fixtures and Traffic Poles

Circular (CHS) EN 10219 pipes are widely used in roadside and traffic-related components:

Traffic signal poles, CCTV posts, and street lighting masts: Aesthetic, strong, and wind-resistant

Guardrails and noise barrier supports: Used along highways and expressways

Signage frames and directional signs: Structurally reliable and customizable

These applications benefit from the material’s long lifespan and ease of maintenance, contributing to reduced lifecycle costs—an important factor in modern transportation planning.

Application of EN 10219 Steel Pipes in Urban Bridges

Urban bridges are a vital component of a city’s transportation network. They handle high volumes of pedestrian and vehicular traffic while also serving as key elements of urban aesthetics and landscape design. To meet these structural and visual demands, EN 10219 steel pipes have become widely used in modern bridge construction, especially as versatile and reliable infrastructure structural tubes.

1. Used in Guardrails and Barrier Systems

Square (SHS), rectangular (RHS), and circular (CHS) EN 10219 steel sections are commonly applied in bridge railing systems, offering the following advantages:

High safety performance: Able to withstand vehicular or pedestrian impact and meet crash-resistance standards

Modern and aesthetic design: Clean, geometric profiles ideal for urban architectural styling

Efficient fabrication and installation: Manufactured to standardized sizes, easy to weld and assemble

Excellent corrosion resistance: Suitable for outdoor environments with optional hot-dip galvanizing or powder coating

In many EN 10219 engineering cases, steel pipe railings are used in urban viaducts, pedestrian overpasses, and expressway bridges, combining functionality with modern appearance.

2. Structural Support for Lightweight Bridges

Beyond railings, EN 10219 steel pipes are also used in:

Main and secondary support structures: Ideal for pedestrian bridges and bike bridges requiring lighter load-bearing materials

Architectural and landscape bridge frameworks: Supporting truss, arch, or spatial designs in long-span or decorative bridges

Temporary or permanent shoring and support systems: Used in retrofitting, reinforcement, or new bridge construction

As infrastructure structural tubes, EN 10219 pipes offer high strength with reduced weight and can replace traditional beams or channels, enabling more flexible and efficient bridge designs.

3. Integration with Utility Functions (Municipal Pipelines)

Urban bridges often serve dual roles by supporting utility crossings. EN 10219 steel pipes are frequently used for:

Protective casing for municipal pipelines: Carrying water, gas, electricity, and telecom lines across bridges

Pipe support frames under the bridge deck: For drainage, cabling, and multi-utility conduits

Poles and fixtures: Supporting lighting, surveillance, or signaling equipment installed on the bridge

This multifunctional use not only increases space utilization but also showcases EN 10219’s adaptability in combining structural and service functions.

Other Municipal and Infrastructure Applications of EN 10219 Steel Pipes

Beyond their vital roles in municipal pipelines and urban bridges, EN 10219 steel pipes are widely used in various other municipal and infrastructure fields. Thanks to their high strength, excellent machinability, and corrosion resistance, they serve as versatile infrastructure structural tubes solutions.

1. Utility Tunnels and Underground Pipeline Support Systems

With increasing complexity of urban utility networks, utility tunnels have become key infrastructure. EN 10219 steel pipes are commonly used as:

Pipe supports and racks inside utility tunnels, supporting water, drainage, gas, power, and communication municipal pipelines;

Structural frameworks and enclosures, enhancing overall tunnel stability and seismic resistance;

Temporary construction supports, ensuring safety and efficiency during installation.

Numerous EN 10219 engineering cases confirm the excellent load-bearing capacity and durability of these steel pipes, making them indispensable for utility tunnel construction.

2. Public Transportation Facilities

EN 10219 steel pipes play roles in bus shelters, subway stations, and rail transit equipment supports:

Bus shelter frames: Lightweight, strong, and easy to assemble and maintain;

Support for rail transit equipment, such as signaling and surveillance installations;

Safety railings and protective barriers around rail tracks, enhancing operational safety.

These applications showcase EN 10219 steel pipes’ flexibility and reliability in diverse municipal constructions.

3. Municipal Landscaping and Urban Furniture

In urban landscaping projects, EN 10219 steel pipes are used for:

Pergolas and pavilion structures: Durable and visually appealing for long-term outdoor use;

Lamp posts and decorative poles, complementing bridge and road lighting systems;

Fencing and barriers in parks and municipal squares for safety and access control.

Surface treatments like hot-dip galvanizing and coating ensure excellent corrosion resistance, suitable for harsh urban environments.

4. Water Supply, Drainage, and Stormwater Management Facilities

In water management, EN 10219 steel pipes serve as:

Protective casings for stormwater and drainage pipes, offering mechanical protection when pipes cross roads or other obstacles;

Inspection chamber support frames, reinforcing chamber integrity to prevent settlement and deformation;

Support structures for stormwater pump stations, ensuring stable operation of equipment.

These applications ensure stability and durability of municipal water systems, reducing maintenance costs.

5. Representative EN 10219 Engineering Cases

Large-scale utility tunnel project: EN 10219 rectangular pipes formed multi-layer pipe support frameworks, enabling efficient spatial arrangement of various municipal pipelines;

Rail transit station equipment racks: EN 10219 square tubes used for mounting signaling and communication equipment, meeting seismic and anti-corrosion requirements;

Urban park pergola: EN 10219 circular pipes created stable and elegant structures, enhancing urban landscape quality.

In summary, EN 10219 steel pipes stand out for their excellent strength and processing performance, making them the ideal choice in construction, machinery manufacturing, and many other industries. Whether you’re an engineer or a buyer, understanding their application advantages can help you make smarter decisions. Stay tuned for more steel pipe insights and take your expertise to the next level!