- 1. Chemical Composition and Mechanical Properties of S235JR

- 2. Table 1: Chemical Composition (Cast Analysis, Mass Fraction %)

- 3. Table 2: Mechanical Properties (Thickness ≤ 40mm)

- 4. Meaning of S235JRH Characters

- 5. Applications of S235JRH Steel Pipes

- 6. Specifications of EN 10219 S235JRH Steel Pipes

- 7. Countries and Regions Where This Standard and Steel Grade Are Commonly Used

- 8. Why choose LONGMA as the supplier of EN 10219 S235JRH LSAW steel pipes?

In the field of steel structures, S235JRH longitudinal submerged arc welded (LSAW) steel pipes under the EN10219 standard are widely used cold-formed welded hollow sections. As a typical representative of non-alloy structural steels, they have become the preferred material for many projects due to their stable performance and strict production standards.

Chemical Composition and Mechanical Properties of S235JR

According to the EN10219 standard, the chemical composition and mechanical properties of S235JR hollow sections are as follows:

Table 1: Chemical Composition (Cast Analysis, Mass Fraction %)

| Element | Maximum Content (%) |

| Carbon (C) | 0.17 |

| Manganese (Mn) | 1.40 |

| Silicon (Si) | 0.35 |

| Sulfur (S) | 0.035 |

| Phosphorus (P) | 0.035 |

| Oxygen (O) | 0.010 |

Table 2: Mechanical Properties (Thickness ≤ 40mm)

| Performance Index | Value |

| Yield Strength (ReH) | ≤16mm: 235MPa; >16-40mm: 225MPa |

| Tensile Strength (Rm) | 360-510MPa |

| Elongation (A) | ≥24% (thickness > 3mm); ≥17% (thickness ≤ 3mm) |

| Impact Energy (KV) | 27J (room temperature 20℃) |

Meaning of S235JRH Characters

S235JRH is the standardized designation for this section in the EN10219 standard, where each character has a specific meaning:

- S stands for Structural Steel;

- 235 indicates that the yield strength of the steel is 235 MPa;

- J means the steel has undergone impact testing and the impact energy meets the requirement of 27J (at +20°C);

- R indicates that the steel pipe has undergone cold bending treatment and has good plasticity;

- H represents that the steel pipe is a welded pipe (Hollow).

Therefore, S235JRH longitudinal submerged arc welded steel pipe is a cold-formed welded structural steel pipe with excellent plasticity and toughness, widely used in multiple engineering fields.

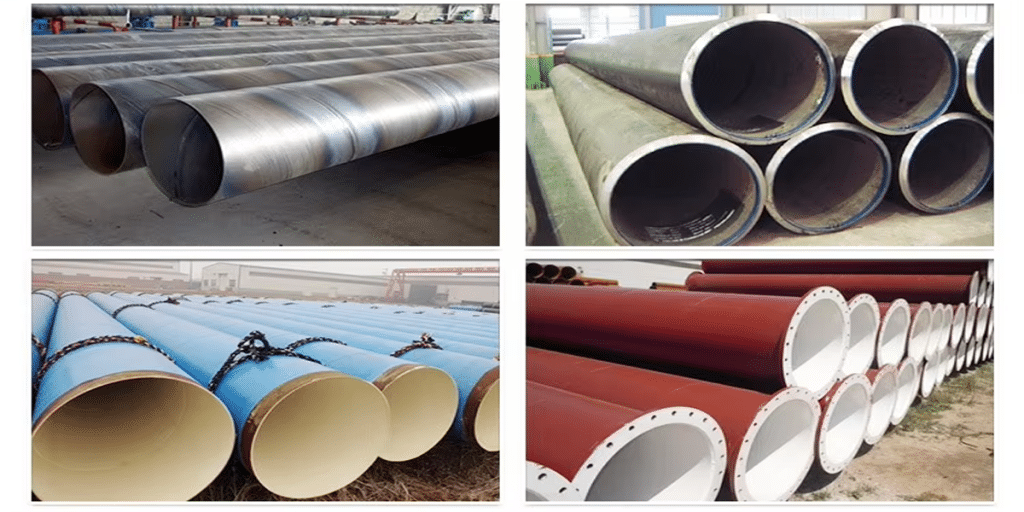

Applications of S235JRH Steel Pipes

S235JRH steel pipes are mainly used for structural purposes, such as building frames, bridge structures, mechanical equipment supports, etc. Due to their excellent mechanical properties and good processing performance, S235JRH steel pipes are particularly suitable for the following fields:

- Construction industry: used for supporting pipes, columns, etc. in building structures;

- Transportation field: used for manufacturing supports and connectors of vehicles such as automobiles, ships, and railways;

- Machinery industry: used for equipment supports, mechanical frames, conveying pipes, etc.;

- Municipal engineering: such as supporting structures of infrastructure like bridges and tunnels.

Specifications of EN 10219 S235JRH Steel Pipes

According to the EN10219-2:2006 standard, the specifications of S235JRH longitudinal submerged arc welded steel pipes cover:

- Outer diameter (circular): up to 2500mm;

- Side length (square/rectangular): maximum 500×500mm for square, maximum 500×300mm for rectangular;

- Wall thickness: maximum 40mm;

- Length: common lengths are 6m and 12m, which can be customized according to order requirements (random length, fixed length, etc., with tolerances meeting the standard).

During the production process, the welds need to pass non-destructive testing such as ultrasonic and eddy current testing to ensure welding quality.

Countries and Regions Where This Standard and Steel Grade Are Commonly Used

The EN10219 standard is widely used in Europe and many regions around the world, especially in markets that require compliance with high-quality standards. S235JRH steel pipes are commonly used in the following countries and regions:

- Europe: EN10219 is the main standard in various European countries, widely used in construction, machinery, automobile and other industries;

- China: In the domestic market, EN10219 is gradually being used in welded steel pipes for construction and municipal engineering;

- United States: Although the United States has its own standards (such as ASTM A500), S235JRH steel pipes have also begun to be used in some specific projects;

- Japan: It also has certain applications in the construction industry, especially in some large-scale infrastructure projects.

Why choose LONGMA as the supplier of EN 10219 S235JRH LSAW steel pipes?

LONGMA, as a professional manufacturer of round ERW/LSAW steel pipes, has rich production experience and high-precision manufacturing technology. Choosing LONGMA as the supplier of EN 10219 S235JRH LSAW steel pipes has the following advantages:

- Strict quality control: LONGMA conducts strict quality control over the production process of steel pipes to ensure that each steel pipe meets the requirements of the EN10219 standard;

- Customized services: Provide steel pipes of various specifications according to different customer needs, including customized length, wall thickness and outer diameter;

- Efficient delivery capability: LONGMA has strong production capacity and an efficient logistics system to ensure on-time delivery;

- Competitive prices: By optimizing production processes and purchasing raw materials, LONGMA can provide customers with competitive prices.

EN10219 S235JRH longitudinal submerged arc welded steel pipe is a high-quality structural steel pipe suitable for various engineering projects. With its excellent mechanical properties and wide application fields, it has significant market demand worldwide. Choosing a reliable supplier like LONGMA will ensure the smooth progress of the project and obtain steel pipes that meet high-standard requirements.