- 1. Overview of ASTM A672 Standard and Material Characteristics

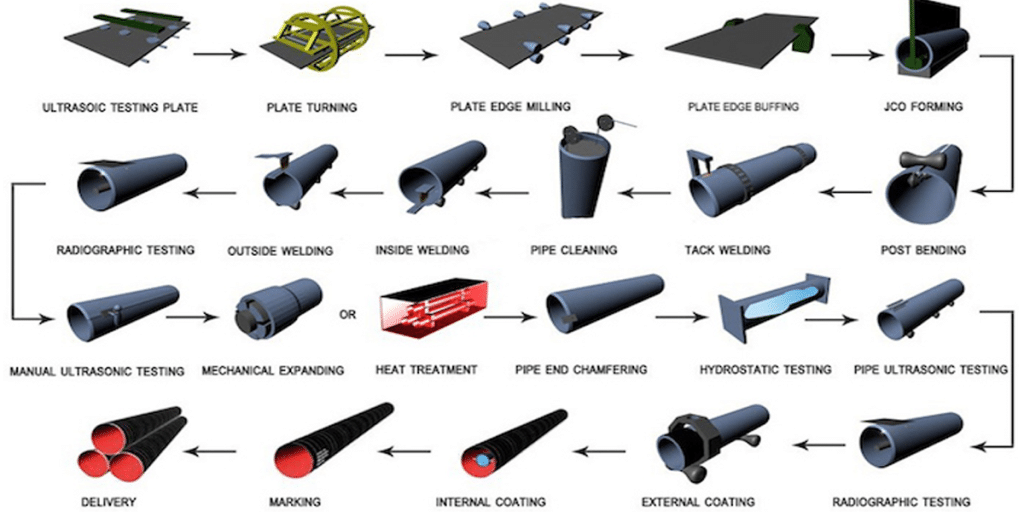

- 2. From Raw Steel to Pipe: The Manufacturing Process of ASTM A672 Pipes

- 3. Quality Control and Non-Destructive Testing

- 4. Comparison: ASTM A672 vs. ASTM A671

- 5. LONGMA’s Manufacturing Advantages

- 6. Conclusion: Quality That Builds Global Trust

In today’s era of rapid infrastructure and energy development, ASTM A672 welded steel pipes have become a key component in oil, gas, chemical, and power projects due to their exceptional strength, weldability, and pressure resistance. As a manufacturer with over 20 years of experience, LONGMA strictly adheres to international standards and employs advanced manufacturing and testing technologies to ensure that every ASTM A672 pipe meets or exceeds performance requirements in strength, toughness, and corrosion resistance.

Overview of ASTM A672 Standard and Material Characteristics

The ASTM A672 standard, established by ASTM International, covers Electric Fusion Welded (EFW) Carbon Steel Pipes used for high-pressure and moderate-temperature service. These pipes are ideal for critical piping systems in refineries, power stations, and industrial plants.

| Item | Technical Requirement | Description |

| Standard | ASTM A672 / ASME SA672 | For pressure vessels and high-temperature pipelines |

| Manufacturing Method | EFW (Electric Fusion Welded) | Electric arc welding for seam formation |

| Common Grades | C60, C65, C70 | Classified by mechanical strength |

| Common Classes | Class 12, Class 22, Class 32 | Defined by heat treatment and testing requirements |

| Key Features | Excellent ductility and toughness | Suitable for high-pressure and low-temperature use |

Among these, ASTM A672 C65 CL22 is the most commonly used grade in industrial projects, offering an excellent balance between strength and cost.

From Raw Steel to Pipe: The Manufacturing Process of ASTM A672 Pipes

LONGMA’s production line is fully digitalized, ensuring complete traceability and process control from raw steel to finished product.

- Raw Material Inspection

Steel plates conforming to ASTM A516 or A204 are analyzed using spectrometers to ensure the ASTM A672 materialmeets the chemical composition limits for C, Mn, and Si. - Forming and Welding

Steel plates are rolled into cylindrical shapes using advanced plate bending equipment. Through the Electric Fusion Welding (EFW)process, the seam is fused using multiple passes to ensure dense, defect-free welds. - Heat Treatment Process

-

- Class 12:Local post-weld heat treatment

- Class 22:Full-body normalization and tempering

- Class 32:High-temperature normalization for enhanced toughness

For ASTM A672 C65 CL22, LONGMA applies full-pipe normalization followed by controlled cooling to ensure uniform microstructure and reduced residual stress.

- Mechanical Testing

Each pipe undergoes comprehensive mechanical tests, including: -

- Tensile and yield strength

- Impact toughness (Charpy Test)

- Flattening and bending tests

All tests are performed in LONGMA’s in-house laboratory, ensuring real-time data recording and quality traceability.

Quality Control and Non-Destructive Testing

LONGMA’s in-house non-destructive testing (NDT) lab is equipped with Ultrasonic Testing (UT), Radiographic Testing (RT), Magnetic Particle (MT), and Dye Penetrant (PT) equipment. Every ASTM A672 pipe must pass the following tests before delivery:

| Test Type | Method | ASTM Standard Reference |

| Ultrasonic Test | ASTM E213 | Detects internal weld defects |

| Radiographic Test | ASTM E94 | Identifies porosity and slag inclusions |

| Hydrostatic Test | ASTM A999 | Ensures pressure resistance |

| Chemical Analysis | ASTM E415 | Verifies chemical composition accuracy |

These rigorous tests guarantee the mechanical reliability and integrity of every LONGMA-manufactured pipe.

Comparison: ASTM A672 vs. ASTM A671

| Feature | ASTM A671 | ASTM A672 |

| Material Type | Low alloy or carbon steel | Carbon steel |

| Welding Method | EFW or SAW | Primarily EFW |

| Temperature Range | High temperature | Medium to high temperature |

| Heat Treatment | Optional | Normalization or controlled cooling |

| Common Grades | CC60, CC65, CC70 | C60, C65, C70 |

While both standards are widely used, ASTM A672 focuses more on pressure containment and weld quality, making it a preferred choice for power plants, chemical pipelines, and cross-border energy systems.

LONGMA’s Manufacturing Advantages

- 20+ Years of Expertise— Extensive experience in welded steel pipe production and global engineering projects.

- In-House Laboratory— Complete quality testing from raw materials to final inspection.

- Global Certifications— ISO 9001, PED, and API 5L certified production system.

- Custom Production Capability— Tailored manufacturing for different grades, such as ASTM A672 C65 CL22, with adjustable wall thickness and class requirements.

Conclusion: Quality That Builds Global Trust

From steel plate to finished pipe, LONGMA upholds the highest production and inspection standards to ensure the superior quality of every ASTM A672 welded steel pipe. Through continuous innovation and precision control, LONGMA has become one of the most trusted ASTM A672 pipe suppliers worldwide.

Whether for power plant pipelines, chemical processing lines, or large-scale infrastructure projects, choosing LONGMA means choosing reliability, safety, and long-term performance.