- 1. Overview of the ASTM A672 Standard

- 2. Comparative Analysis: C60 vs. C65 vs. C70

- 3. In-House Testing and Quality Assurance

- 4. Manufacturing and Heat Treatment Differences

- 5. ASTM A671 vs. ASTM A672: Key Differences

- 6. LONGMA Brand Strength and Global Trust

- 7. Conclusion: Choose the Right Grade, Trust LONGMA

In modern power plants, petrochemical systems, and high-pressure steam pipelines, ASTM A672 steel pipes are widely used for their excellent mechanical strength, weld integrity, and reliability. Among these, Grades C60, C65, and C70 are the most common materials under the ASTM A672 standard, each offering distinct advantages in strength, temperature tolerance, and cost-efficiency.

This article explores the key performance differences between these grades, providing engineers and procurement professionals with data-driven insights for selecting the right material.

Overview of the ASTM A672 Standard

ASTM A672 is a specification developed by ASTM International for Electric Fusion Welded (EFW) carbon steel pipes, designed for moderate to high-temperature and pressure applications such as steam, water, oil, and gas transportation.

Common grades include ASTM A672 C60, ASTM A672 C65, and ASTM A672 C70, each manufactured and tested according to the ASTM A672 specification.

| Item | Description |

| Standard | ASTM A672 / ASME SA672 |

| Manufacturing Method | Electric Fusion Welding (EFW) |

| Common Grades | C60, C65, C70 |

| Common Classes | CL12, CL22, CL32 |

| Typical Applications | Power plants, chemical plants, boilers, heat exchangers, high-pressure water lines |

Comparative Analysis: C60 vs. C65 vs. C70

The main differences among ASTM A672 pipe grades lie in their tensile strength, heat treatment method, and service temperature range.

| Property | ASTM A672 C60 | ASTM A672 C65 | ASTM A672 C70 |

| Yield Strength (MPa) | ≥240 | ≥260 | ≥275 |

| Tensile Strength (MPa) | 415–550 | 450–600 | 485–620 |

| Recommended Service Temp | ≤450°C | ≤500°C | ≤530°C |

| Heat Treatment | Normalized | Normalized + Tempered | High-Temp Normalized |

| Impact Toughness | Good | High | Excellent |

| Typical Application | Medium-pressure water lines | High-pressure steam pipelines | Superheated steam & heat exchangers |

As shown above, ASTM A672 C70 delivers the highest temperature and pressure tolerance, while C60 offers an economical balance of strength and weldability — making it the most popular choice for general engineering projects.

In-House Testing and Quality Assurance

LONGMA operates a fully equipped in-house testing laboratory to ensure consistent quality control across every production batch. Every ASTM A672 material undergoes a series of inspections according to ASTM standards before delivery.

| Test Item | Standard Reference | Objective |

| Chemical Composition | ASTM E415 | Verify elemental composition |

| Tensile & Yield Strength | ASTM A370 | Confirm mechanical performance |

| Impact (Charpy) Test | ASTM E23 | Evaluate low-temperature toughness |

| Ultrasonic Test (UT) | ASTM E213 | Detect internal welding defects |

| Radiographic Test (RT) | ASTM E94 | Examine weld uniformity |

| Hydrostatic Test | ASTM A999 | Ensure sealing and pressure resistance |

Each ASTM A672 C65 CL22 or ASTM A672 C70 pipe is delivered with a Mill Test Certificate (MTC), guaranteeing traceability and compliance with international standards.

Manufacturing and Heat Treatment Differences

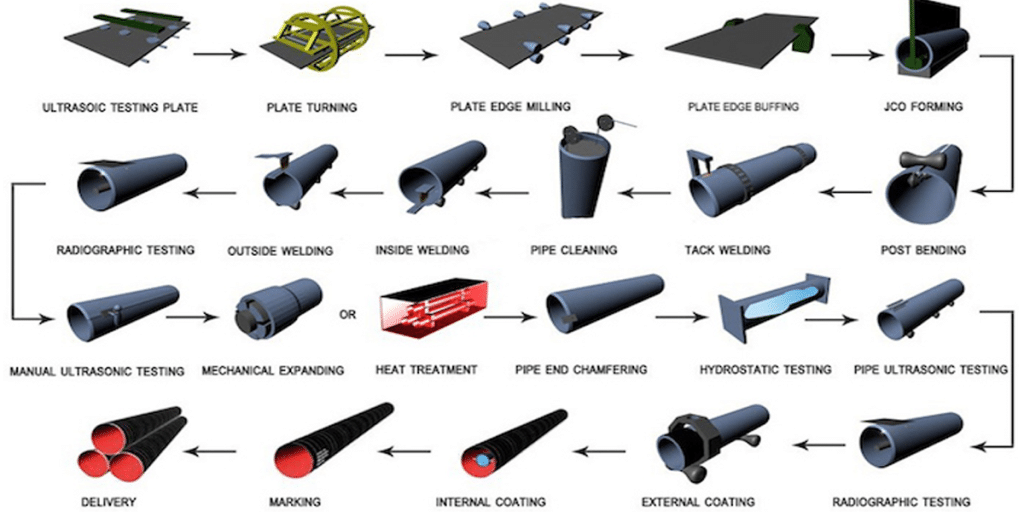

- EFW Welding Technology

All ASTM A672 pipes are manufactured using the Electric Fusion Welding process. LONGMA’s automated welding line continuously monitors current, voltage, and temperature to ensure weld consistency equivalent to base metal strength. - Heat Treatment Variations

- C60: Normalized to refine grain structure.

- C65 CL22: Normalized and tempered to enhance ductility.

- C70 CL32: High-temperature normalization for superior strength and creep resistance.

- Dimensional and Surface Accuracy

Automatic ultrasonic thickness gauges are used to guarantee wall thickness uniformity as required by the ASTM A672 specification.

ASTM A671 vs. ASTM A672: Key Differences

| Comparison Item | ASTM A671 | ASTM A672 |

| Material Type | Carbon or low-alloy steel | Carbon steel |

| Welding Method | EFW or SAW | EFW only |

| Heat Treatment | Optional | Mandatory |

| Typical Application | Pressure vessels | Steam, water, and oil pipelines |

| Weld Consistency | High | Higher (tighter process control) |

Conclusion: ASTM A672 provides better weld quality and structural stability for high-temperature and high-pressure service compared to ASTM A671, making it ideal for steam and hot water systems.

LONGMA Brand Strength and Global Trust

With over 20 years of experience, LONGMA has become a leading China ASTM A672 exporter, supplying ASTM A672 C60, C65, and C70 steel pipes to more than 30 countries worldwide.

LONGMA’s Competitive Advantages:

- End-to-End Traceable Quality System– From raw material to finished pipe.

- International Certifications– ISO 9001, PED, and API 5L approved.

- Custom Production Capability– Flexible production for ASTM A672 C60 CL22, C65 CL22, C70 CL32, etc.

- Reliable Delivery & Fast Response– Trusted by EPC contractors globally.

Conclusion: Choose the Right Grade, Trust LONGMA

Selecting the proper grade of ASTM A672 pipe is essential to ensure safety, efficiency, and long-term reliability in demanding systems.

Whether C60 for cost-effective pipelines, C65 for high-pressure systems, or C70 for extreme conditions, LONGMA guarantees excellence through strict testing, precision manufacturing, and global standard compliance.