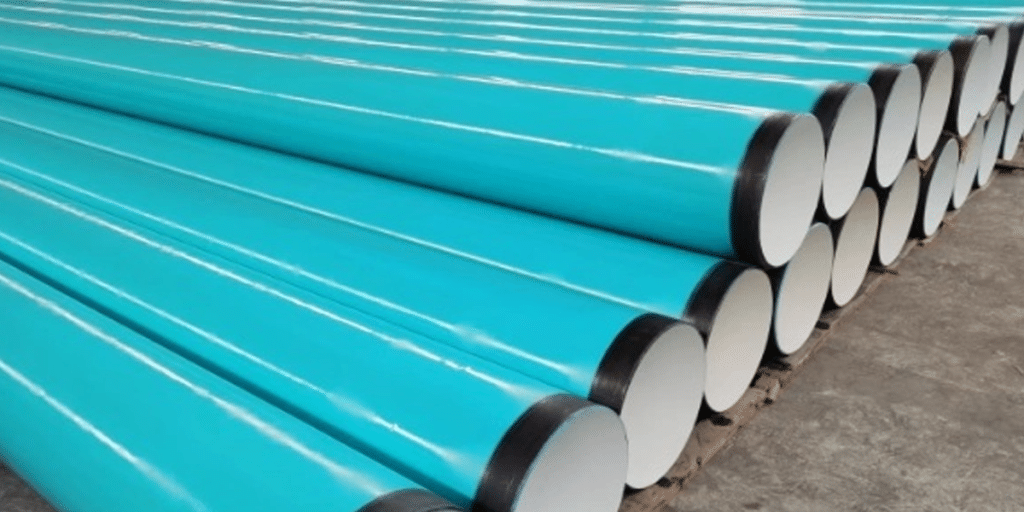

As one of the most widely used electric fusion welded (EFW) carbon steel pipes, ASTM A672 pipe is essential for high-pressure applications in oil, gas, and power generation industries. However, during manufacturing, improper control of welding parameters, raw material quality, or heat treatment can lead to defects that affect the pipe’s strength, reliability, and compliance with the ASTM A672 specification.

This article provides an in-depth analysis of the common defects found in ASTM A672, their causes, testing standards, and preventive measures — helping buyers understand quality assurance processes and build confidence in choosing reliable suppliers such as LONGMA Steel Pipe, a leading China ASTM A672 exporter with over 20 years of production experience.

Overview of ASTM A672 Standard

The ASTM A672 specification covers EFW carbon steel pipes produced from pressure vessel-quality plate. These pipes are typically used for moderate to high-temperature services, such as in steam lines, pressure systems, and power plants.

Basic Overview of ASTM A672 Grades

| Grade Type | Typical Class | Key Property | Common Application |

| ASTM A672 C60 | CL22 | High toughness and weld integrity | Steam pipelines |

| ASTM A672 C65 | CL22 | Enhanced mechanical strength | Oil and gas transport |

| ASTM A672 C70 | CL32 | Excellent impact resistance | Power plant systems |

Each grade (e.g., ASTM A672 C60, ASTM A672 C65 CL22, ASTM A672 C70) differs mainly in its tensile properties, chemical composition, and heat treatment class, influencing performance in different temperature and pressure environments.

Common Defects in ASTM A672 Pipe Manufacturing

Even with strict process controls, some defects may occur during ASTM A672 pipe production. Understanding these helps both manufacturers and buyers ensure product quality and compliance.

| Defect Type | Description | Main Causes | Detection Methods |

| Weld Porosity | Tiny gas holes in weld metal | Contaminated surface, improper gas shielding | Radiographic Testing (RT), Ultrasonic Testing (UT) |

| Lack of Fusion | Incomplete bonding between weld and base metal | Low heat input or improper alignment | UT, Visual Examination |

| Slag Inclusion | Non-metallic inclusions trapped in weld | Improper slag removal or electrode angle | RT, Magnetic Particle Testing (MT) |

| Cracks (Longitudinal/Transverse) | Cracks due to stress concentration | Improper cooling, high residual stress | MT, Dye Penetrant Testing (PT) |

| Lamination | Layer separation in steel plate | Defective base material or improper rolling | UT during plate inspection |

Non-Destructive Testing (NDT) in Quality Assurance

The ASTM A672 specification mandates several non-destructive testing (NDT) methods to detect internal or surface discontinuities without damaging the product. These tests play a key role in preventing defects from reaching customers.

Common NDT Methods for ASTM A672 Pipes

| NDT Method | Standard Reference | Test Objective | Frequency |

| Ultrasonic Testing (UT) | ASTM E213 | Detect internal flaws or laminations | 100% on weld seam |

| Radiographic Testing (RT) | ASTM E94 | Examine weld integrity | On specified number of joints per lot |

| Magnetic Particle Testing (MT) | ASTM E709 | Identify surface/subsurface cracks | After welding and machining |

| Dye Penetrant Testing (PT) | ASTM E165 | Detect fine surface cracks | On weld surfaces |

| Visual Inspection (VT) | ASTM A672 Sec. 12 | Confirm surface condition and weld quality | All pipes before dispatch |

At LONGMA’s internal laboratory, all ASTM A672 carbon steel pipes undergo multi-stage testing — including UT, MT, and hydraulic pressure tests — ensuring compliance with ASTM A672 C60 CL22, ASTM A672 C65 CL22, and ASTM A672 C70 requirements.

Preventive Measures for Common Defects

To minimize defects and ensure mechanical integrity, manufacturers like LONGMA Steel Pipe implement comprehensive quality control systems across each production stage.

| Process Stage | Preventive Measure | Expected Outcome |

| Plate Inspection | Verify chemical composition and lamination using UT | Prevent internal separation and inclusions |

| Edge Preparation | Use automatic beveling machines | Achieve uniform weld groove |

| Welding Control | Maintain optimal temperature, current, and electrode quality | Reduce porosity and lack of fusion |

| Heat Treatment | Follow controlled furnace cycles | Relieve residual stress and enhance ductility |

| Final Inspection | Apply 100% visual and dimensional checks | Guarantee ASTM A672 specification compliance |

These measures ensure that every ASTM A672 pipe meets customer expectations for durability, safety, and long service life under harsh operating conditions.

Why Choose LONGMA for ASTM A672 Pipe Supply

- 20+ Years of Manufacturing Expertise: Specializing in ASTM A672 EFW pipes, LSAW pipes, and related grades.

- Comprehensive Testing Capability: In-house laboratory equipped for UT, RT, MT, and chemical analysis.

- Global Export Certification: Products meet ASME, API 5L, ASTM, and international project standards.

- Strong After-Sales Support: Technical documentation and third-party inspection available.

With its commitment to excellence, LONGMA continues to be a trusted ASTM A672 exporter for international infrastructure and energy projects.

Conclusion

Understanding the common manufacturing defects and their prevention in ASTM A672 pipes helps ensure quality, reduce procurement risks, and improve system reliability. Through rigorous testing and quality assurance — from plate inspection to final NDT — LONGMA Steel Pipe guarantees products that meet or exceed international standards.

For reliable sourcing of ASTM A672 C60, ASTM A672 C65 CL22, or ASTM A672 C70 pipes, choose LONGMA, your trusted partner for high-performance steel piping solutions.