- 1. Differences in Standards and Definitions

- 2. Key Parameter Comparison

- 3. Why They Are Often Considered “Equivalent”

- 4. Recommended Testing Methods (to Reduce Procurement Risk)

- 5. LONGMA’s Testing & Quality Control Strength

- 6. Practical Procurement Recommendations

- 7. Conclusion — Equivalent in Practice, But Data Matters

In engineering procurement and structural design, one of the most frequently asked questions is:Can the European standard steel S235JR (EN 10025-2) be interchanged with the American standard ASTM A36?

The short answer: They are similar in most general structural applications, but not strictly identical. There are key differences in mechanical properties, delivery conditions, and impact toughness requirements, which must be verified through testing and certification to minimize procurement risk.

Differences in Standards and Definitions

S235JR (EN 10025-2)

- Non-alloy structural steel with a minimum yield strength of 235 MPa.

- The “JR” designation indicates an impact energy of ≥27 J at +20°C, provided when required by the contract.

- The standard defines delivery conditions, chemical composition limits, and mandatory tests.

ASTM A36 / A36M

- Carbon structural steel used for plates, bars, and structural shapes.

- Specifies chemical composition and mechanical properties such as tensile and yield strength.

- Does not require impact toughness testingby default; it depends on purchase order or contractual agreement.

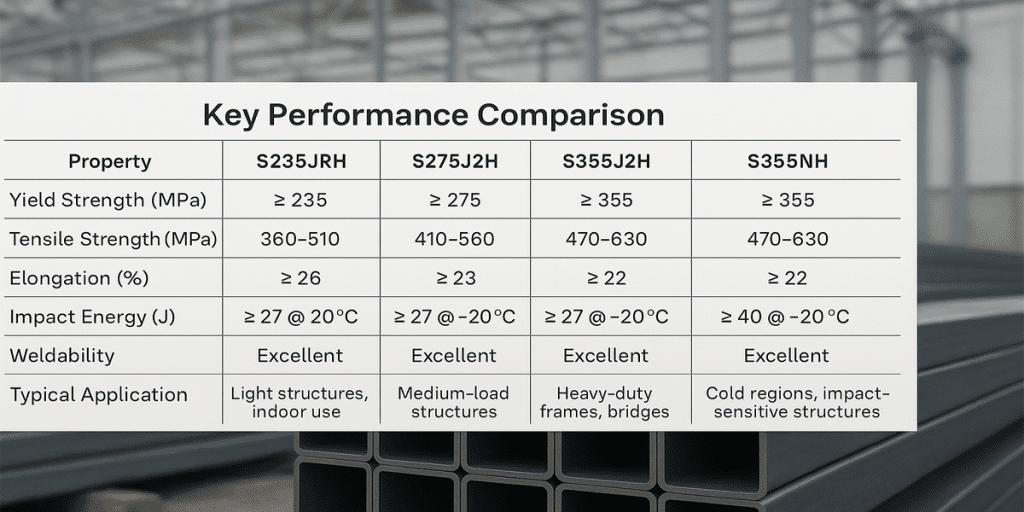

Key Parameter Comparison

| Property | S235JR (EN 10025) | ASTM A36 |

| Nominal Yield Strength | ≥235 MPa (varies with thickness) | ~250 MPa (size dependent) |

| Tensile Strength | ~360–510 MPa | 400–550 MPa |

| Max. Carbon Content | ≤0.17–0.21 (depending on thickness) | ≤0.26 |

| Impact Toughness | “JR” = ≥27 J @ +20°C (when required) | Not mandatory unless specified |

| Typical Application | European structural projects requiring impact verification | U.S. structural projects and general applications |

Data sourced from EN and ASTM specifications and industrial databases.

Note: Actual mechanical and chemical values depend on plate thickness, delivery condition (AR, N), and production batch. True equivalence must always be verified using Mill Test Certificates (MTCs) and laboratory test data.

Why They Are Often Considered “Equivalent”

Both steels are low-carbon structural steels with similar weldability and formability. In many general applications without extreme temperature or corrosion exposure, they perform comparably—hence the assumption of equivalence.

However, S235JR explicitly includes an impact energy requirement (JR), while A36 does not unless contractually required. For safety-critical or low-temperature applications, this difference can present a serious risk if overlooked.

Recommended Testing Methods (to Reduce Procurement Risk)

Before confirming interchangeability, it is essential to perform standardized laboratory tests and define testing requirements clearly in contracts.

LONGMA’s in-house laboratory can perform all required inspections under international standards.

| Test Item | Purpose | Standard Reference | Main Procedure | Evaluation & Reporting |

| Chemical Composition Analysis | Verify compliance with chemical limits and ensure welding & mechanical reliability | EN 10025-2 / ASTM A36; methods per ISO 14284 / ASTM E415 | OES spectrometry or wet analysis, samples from representative sections | Each element must meet specified limits; full report attached to MTC |

| Tensile Test | Determine yield strength, tensile strength, elongation | ISO 6892-1 / ASTM A370 (or E8) | Longitudinal or transverse specimen pulled to fracture at room temp. | Results must meet standard values; raw data and curve attached |

| Charpy V-Notch Impact Test | Evaluate toughness at room/low temperature | EN ISO 148-1 / ASTM E23 | 10×10×55 mm specimens, test at +20°C or contract-specified temp. | S235JR-JR ≥27 J @ +20°C; A36 only if requested |

| Hardness Test | Assess strength consistency and heat treatment control | ASTM A370 / ISO 6506 (Brinell) / ISO 6508 (Rockwell) | Apply standard load on polished surface | Values within standard tolerance |

| Bend & Visual Inspection | Assess ductility and surface quality | ASTM A370 / EN 10025 Annex | 180° bend test + surface inspection | No cracks, delamination, or inclusions |

Note:

- All test data must be recorded in the Mill Test Certificate (MTC).

- Tests must be carried out in an accredited lab (LONGMA internal lab or CNAS-certified third party).

- For special projects (bridges, low-temperature vessels), specify additional impact temperatures and sampling frequency in the contract.

LONGMA’s Testing & Quality Control Strength

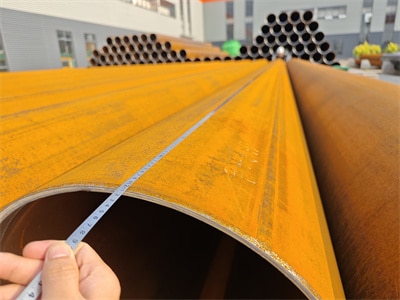

With over 20 years of manufacturing experience, LONGMA operates a fully equipped in-house quality inspection laboratory, covering the entire production process — from raw material to final delivery.

Laboratory Capabilities:

- Optical Emission Spectrometer (OES) for chemical analysis

- 100-ton Universal Tensile Testing Machine (ISO 6892-1 / ASTM A370)

- Charpy Impact Testing Machine (temperature range down to -40°C)

- Brinell and Rockwell Hardness Testers

- Ultrasonic and Magnetic Particle Inspection Systems

All tests follow EN, ASTM, and ISO standards, ensuring reliable, traceable data for every batch of S235JR and A36 steel.

LONGMA’s quality management system meets the requirements of global projects across Europe, the Middle East, and North America, and provides third-party inspection options (BV, SGS, TÜV) for total client assurance.

Practical Procurement Recommendations

- Specify standards and testing in contracts– clearly list EN 10025-2 or ASTM A36, delivery condition (AR/N), required tests (chemical, tensile, impact), and acceptance criteria.

- Always verify and retain the MTC– including OES chemical report, tensile curves, and impact energy results.

- For low-temperature or critical structures, select materials with certified impact data, such as S235JR-JR with verified +20°C toughness.

Conclusion — Equivalent in Practice, But Data Matters

While S235JR and ASTM A36 are similar and often interchangeable for general structural use, calling them “identical” is inaccurate. Differences in impact toughness, composition limits, and delivery conditions mean each must be verified before substitution.

The best practice is to require complete MTC documentation and, if needed, third-party verification.

With its comprehensive testing facilities and strict quality system, LONGMA ensures you receive certified, data-backed steel products — reducing risk and protecting your project’s integrity.