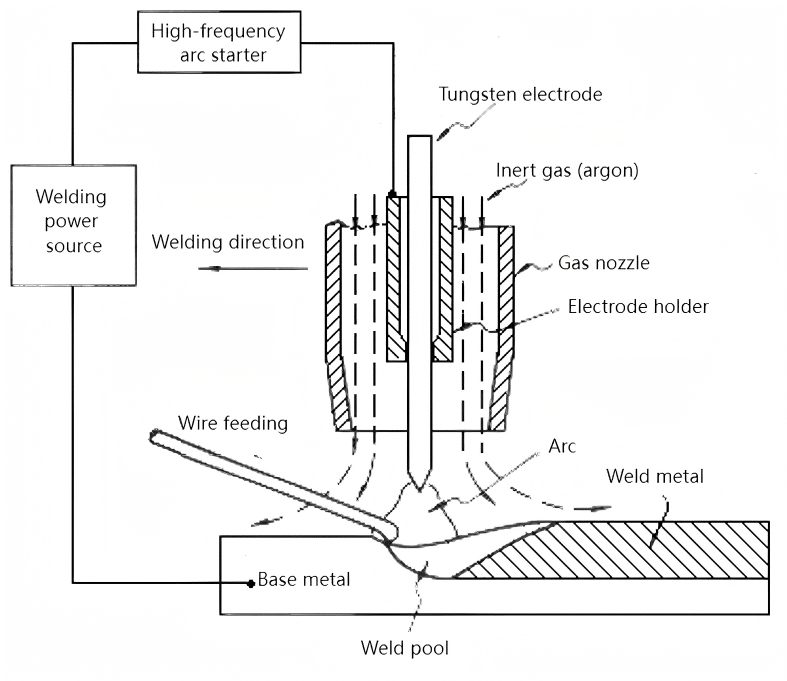

- 1. Advantages and Disadvantages of TIG Welding

- 2. TIG Welding Power Supply

- 3. Core Working Principle

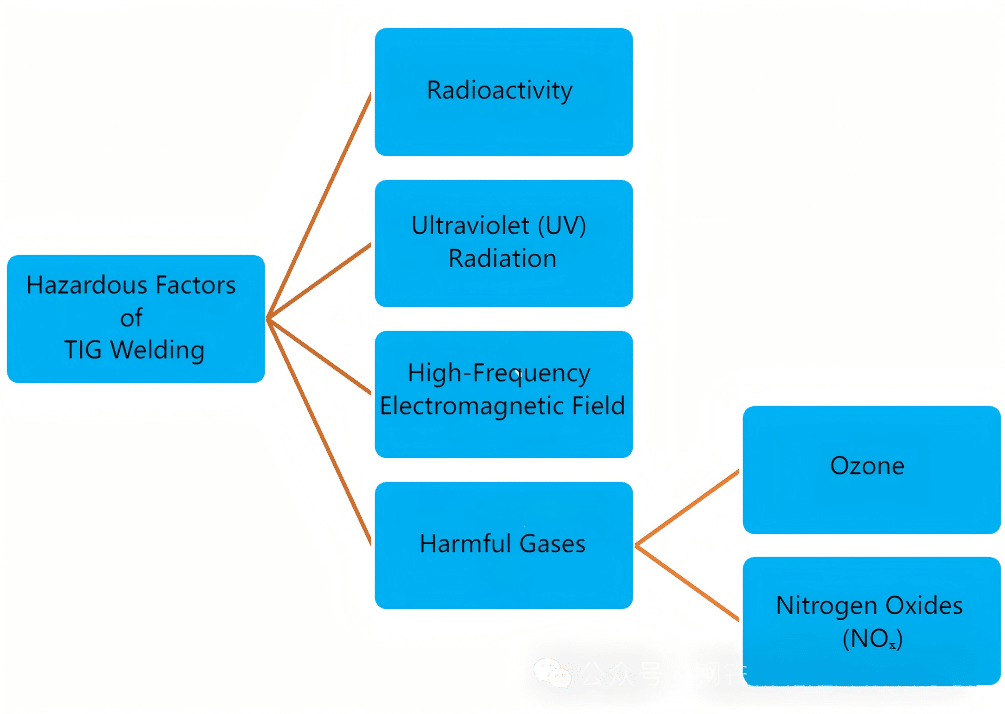

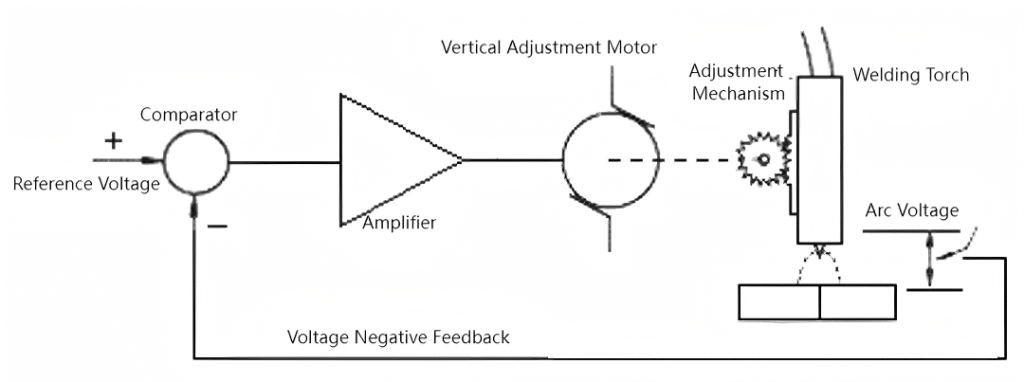

- 4. Arc Physical Process

- 5. Comparison of TIG Welding Modes

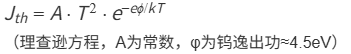

- 6. Key Process Control Points for TIG Welding

- 7. Typical Defects and Countermeasures in TIG Welding

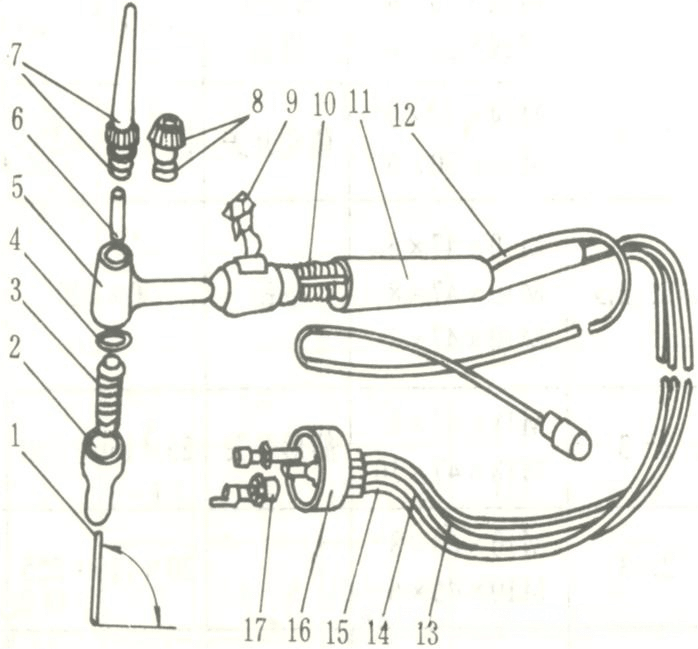

- 8. Key TIG Welding Operation Points

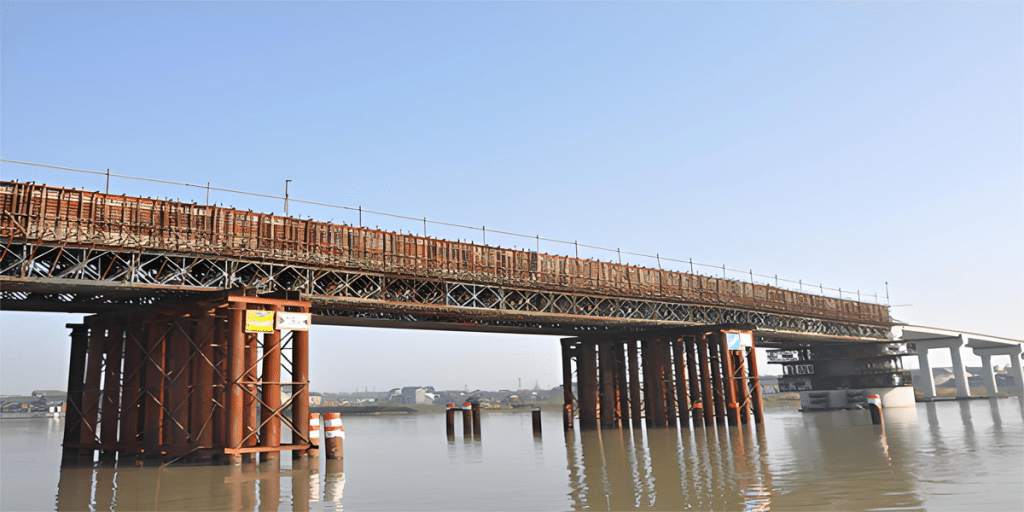

- 9. Typical Application Scenarios of TIG Welding

- 10. Summary of TIG Welding

Tungsten Inert Gas (TIG) Welding is an arc welding process that generates heat between a non-consumable electrode and the workpiece. The electrode rod, weld pool, arc, and the heated area adjacent to the workpiece are all shielded by a gaseous medium to prevent atmospheric contamination. This shielding is provided by a single gas or gas mixture, which must offer full protection—even minute air infiltration can contaminate the weld bead. As a non-consumable electrode inert gas shielded welding process, TIG/GTAW operates on the core principle of igniting and maintaining an arc via a tungsten electrode, melting the base metal or filler wire under argon shielding to achieve high-quality welds.

The following is a systematic analysis:

Advantages and Disadvantages of TIG Welding

1. Advantages

(1) Argon effectively isolates ambient air, does not dissolve in or react with metals, and automatically removes oxide films from the weld pool surface. Thus, it can successfully weld non-ferrous metals, stainless steels, and various alloys that are prone to oxidation and highly chemically reactive.

(2) The tungsten electrode arc is stable—even at very low welding currents (<10A), it can burn steadily. It is particularly suitable for welding thin and ultra-thin sheets. All-position welding is feasible; pulsed TIG welding can reduce heat input, enabling welding of 0.1mm-thick stainless steel.

(3) The heat source and filler wire can be controlled independently, making heat input easy to adjust. It supports welding in various positions and is an ideal method for single-sided welding with double-sided forming.

(4) Since filler wire droplets do not pass through the arc, no spatter is generated, resulting in an aesthetically pleasing weld bead.

2. Disadvantages

(1) Shallow weld penetration, low deposition rate, and relatively low productivity.

(2) Tungsten electrodes have limited current-carrying capacity. Excessively high currents can cause electrode melting and evaporation, with micro-particles potentially entering the weld pool and causing contamination (tungsten inclusion).

(3) Inert gases (argon, nitrogen) are relatively expensive, leading to higher production costs compared to other arc welding methods (e.g., AC manual arc welding, submerged arc welding, CO₂ gas shielded welding).

TIG Welding Power Supply

| Component | Function | Technical Points |

| Tungsten electrode | Ignites and maintains the arc (melting point 3422℃, non-consumable) | Cerium-tungsten (CeO₂) has low electron work function, reducing arc ignition voltage by 20% |

| Argon shielding system | Forms an inert gas barrier | Purity ≥99.99%, flow rate 8-15L/min |

| High-frequency oscillator | Breaks down air to ignite the arc (5-15kV high frequency) | Ionization distance ≤3mm; avoids workpiece damage from contact |

| Constant current power supply | Maintains stable current (fluctuation <±3%) | Controlled by a steeply dropping external characteristic curve |

1. Power Supply

To minimize and eliminate current fluctuations caused by arc length changes, TIG welding requires a power supply with a dropping external characteristic. The current types used in tungsten inert gas welding include: DC electrode negative (DCEN), DC electrode positive (DCEP), and alternating current (AC). Common DC TIG welding machines include models WS-250 and WS-400; AC TIG welding machines include WSJ-150 and WSJ-500; AC/DC TIG welding machines include WSE-150 and WSE-400. (W – Tungsten; S – Multi-purpose.)

DCEN means the workpiece is connected to the positive terminal and the tungsten electrode to the negative terminal. The tungsten electrode generates less heat, is less likely to overheat, and has strong thermionic emission capacity, resulting in a stable and concentrated arc. For the same electrode diameter, a larger current can be used. The workpiece absorbs significant heat, producing a deep, narrow weld pool with high productivity and minimal workpiece shrinkage and deformation. DCEP operates in the opposite manner. Therefore, DCEN is suitable for most metals. For welding aluminum, magnesium, their alloys, and oxidation-prone copper alloys (e.g., aluminum bronze), AC TIG welding is preferred.

2. Control Box

(1) Arc Ignition and Stabilization Devices

- Short-circuit Ignition

Touch the workpiece surface with the tungsten electrode at a nearly perpendicular angle, then quickly lift the electrode to start welding after ignition. Due to the short-circuit contact, large currents are generated, causing significant tungsten electrode wear—this method should be used sparingly.

- High-frequency Ignition

Uses high-frequency high voltage generated by a high-frequency oscillator to break down the gap (approximately 3mm) between the tungsten electrode and the workpiece for arc ignition. It is generally used for initial arc ignition. However, high-frequency oscillators are harmful to the human body and must not be left on continuously.

- High-voltage Pulse Ignition

Applies a high-voltage pulse between the tungsten electrode and the workpiece to ionize the gas medium and ignite the arc. During welding, high-voltage pulses can both ignite and stabilize the arc. After arc ignition, arc stabilization pulses are generated automatically, while ignition pulses cease. Thus, high-voltage pulse ignition is a preferred method.

(2) Welding Sequence Control Device

The welding sequence device must meet the following requirements:

Deliver shielding gas 1.5~4s in advance before welding to purge internal air;

Delay gas shutdown for 5~15s after welding to protect the still-cooling tungsten electrode and weld pool;

Automatically switch on/off the arc ignition and stabilization circuits;

Control the on/off of the power supply;

Automatically reduce current before welding completion to eliminate crater defects and prevent crater cracking—especially critical for circumferential welding and welding heat-sensitive materials.

3. Welding Torch

The welding torch functions to hold the tungsten electrode, conduct welding current, deliver argon flow, and start/stop the welding machine. Torches are classified as small, medium, or large, and by cooling method as air-cooled or water-cooled. Water-cooled torches are mandatory for welding currents exceeding 100A.

4. Gas Supply System and Water Cooling System

(1) Gas Supply System

Composed of an argon cylinder, argon flow regulator, and electromagnetic gas valve.

- Argon Cylinder: Externally painted gray with “Argon” marked in green paint. Maximum pressure: 15MPa; volume: 40L.

- Electromagnetic Gas Valve: Controls gas path on/off, regulated by a time-delay relay to enable pre-purge and post-flow functions.

- Argon Flow Regulator: Reduces and stabilizes pressure, and adjusts argon flow rate.

(2) Water Cooling System

Cools the welding cable, torch, and tungsten electrode. Water cooling is unnecessary for welding currents <100A. For currents >100A, water cooling is mandatory, controlled by a water pressure switch to ensure cooling water is supplied at the required pressure before starting the welding machine.

Core Working Principle

1. Welding Machine Operation Diagram

2. Automatic Arc Length Adjustment Device:

There is a good linear correlation between arc voltage and arc length. Arc voltage feedback PID closed-loop control achieves a precision of 0.3V. Welding Torch Oscillator:

Arc Physical Process

1. Arc Ignition

Arc Ignition Stage

High-frequency pulses ionize argon → electron avalanche effect → formation of a plasma channel (resistance <0.1Ω).

High-frequency high voltage or contact ignition breaks down argon (breakdown voltage ≈2000-5000V), ionizing neutral argon atoms:

e⁻+Ar→Ar⁺+2e⁻

forming an initial electron avalanche (Townsend discharge).

Electrons and ions move directionally under the electric field, forming a current path. The arc voltage drops to 10-20V to maintain combustion.

2. Cathode Region (Tungsten Electrode Tip): Core of Electron Emission

Thermionic Emission (Dominant Mechanism):

The tungsten electrode is heated by current to above 3000K (>2700℃), enabling electrons to gain thermal energy and escape. Current density reaches 10⁶-10⁷ A/m².

Field Emission:

When the electric field intensity near the cathode tip exceeds 10⁹ V/m, quantum tunneling effect enhances electron emission.

Cathode Voltage Drop:

A potential drop of approximately 3-15V forms on the cathode surface, accelerating ion bombardment of the cathode to sustain electron emission.

3. Arc Column Region: High-Temperature Plasma Energy Transfer

Electron Kinetic Energy → Thermal Energy: High-speed electrons collide with neutral atoms/ions, converting kinetic energy into thermal energy (primary heat generation method).

Radiative Heat Transfer: High-temperature plasma radiates ultraviolet and infrared rays.

Plasma Characteristics:

Ionization degree >70%, temperature 6000-8000K, intense particle thermal motion, and continuous impact ionization:

e⁻ + Ar ⇌ Ar⁺ + 2e⁻

Energy Transfer Mechanism:

Arc Constriction Effect:

Electromagnetic constriction force (F∝I²/r) and thermal constriction reduce the arc column diameter to only 2-5mm, with an energy density as high as 10⁴-10⁵ W/cm².

4. Anode Region (Workpiece Surface): Energy Absorption and Weld Pool Formation

Heat Generation from Electron Bombardment:

Electron flow carries kinetic energy (approximately 70% of total arc energy) and impacts the anode surface, converting into thermal energy for weld pool formation:

(Va is the anode voltage drop ≈0-2V, φ is the material work function, VT is the electron thermal kinetic energy))

Anode Spot:

A high-temperature zone (slightly lower than the arc column temperature) forms at the concentrated electron impact point, locally melting the base metal to create the weld pool.

Electron Kinetic Energy → Thermal Energy: High-speed electrons collide with neutral atoms/ions, converting kinetic energy into thermal energy (primary heat generation method).

Radiative Heat Transfer: High-temperature plasma radiates ultraviolet and infrared rays.

Plasma Characteristics:

Ionization degree >70%, temperature 6000-8000K, intense particle thermal motion, and continuous impact ionization:

e⁻ + Ar ⇌ Ar⁺ + 2e⁻ (Dynamic equilibrium) e+Ar⇌Ar+2e (Dynamic equilibrium)

Energy Transfer Mechanism:

Electromagnetic constriction force (F∝I²/r) and thermal constriction reduce the arc column diameter to only 2-5mm, with an energy density as high as 10⁴-10⁵ W/cm².

Comparison of TIG Welding Modes

| Mode | Current Type | Applicable Materials | Advantages |

| DC Electrode Negative (DCEN) | DCEN (Tungsten electrode negative) | Stainless steel/carbon steel/copper alloys | Deep weld penetration, low tungsten electrode heating (70% heat on workpiece) |

| DC Electrode Positive (DCEP) | DCEP (Tungsten electrode positive) | Aluminum-magnesium alloys (oxide film removal) | Cathodic cleaning effect, but severe tungsten electrode overheating |

| Alternating Current (AC) | AC | Aluminum/magnesium alloys (balanced heating) | Combines advantages of DCEN/DCEP; requires arc stabilization circuit |

Cathodic Cleaning Effect:

During DCEP or the negative half-cycle of AC, positive ions bombard and break down oxide films (e.g., Al₂O₃) on the workpiece surface, removing them.

Key Process Control Points for TIG Welding

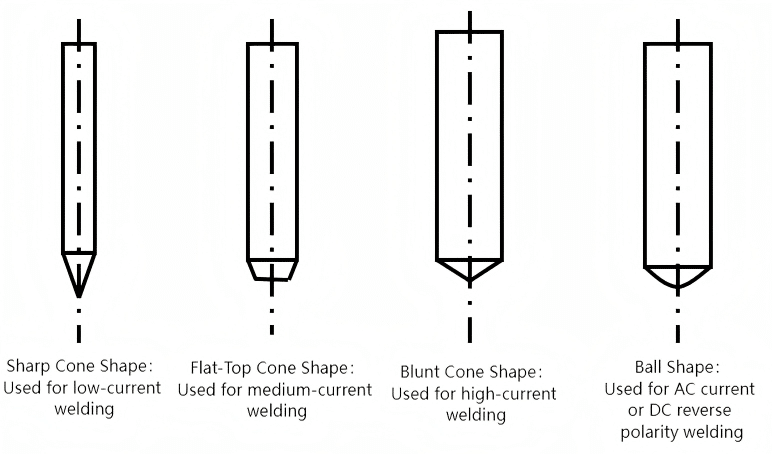

1. Tungsten Electrode Preparation

- Thin sheets (1-3mm): 30° cone angle → concentrated arc.

- Thick sheets (>6mm): 60-90° cone angle → diffused arc.

Tip Angles:

Grinding Requirement: Parallel to the electrode axis (radial grooves cause arc divergence).

2. Enhanced Gas Shielding

- Gas Lens: Multi-layer stainless steel mesh inside the torch laminarizes gas flow (reduces turbulence by 50%).

- Trailing Shield: For titanium alloy welding, an extended gas shield is added to cover high-temperature areas (>400℃) at the weld tail.

3. Heat Input Control:

Frequency 1-100Hz → reduces heat input by 30% and deformation by 60%.

4. Rightward vs. Leftward Welding Techniques

- Rightward Welding: Suitable for thick workpieces. The torch moves from left to right, with the arc pointing to the welded area, facilitating argon shielding of the weld surface from high-temperature oxidation.

- Leftward Welding: Suitable for thin workpieces. The torch moves from right to left, with the arc pointing to the unwelded area for preheating. It allows easy observation and control of weld pool temperature, resulting in good weld formation and easy operation. Leftward welding is generally preferred.

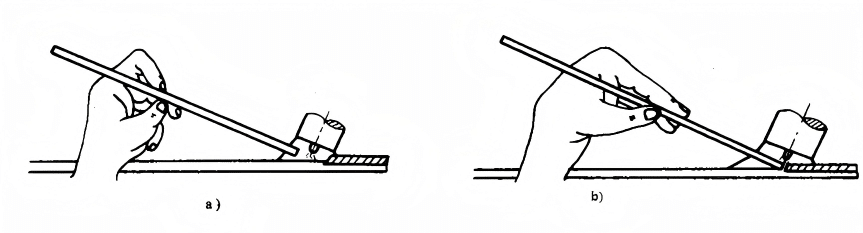

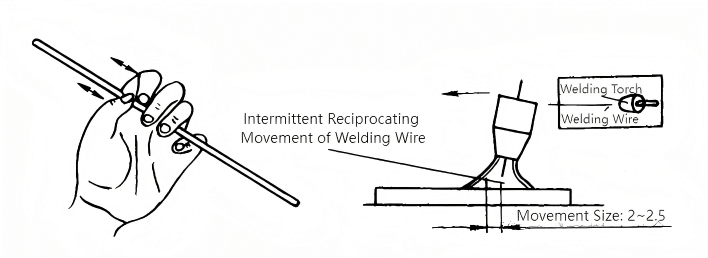

5. Welding Wire Feeding Methods

Method 1: Hold the wire with the thumb and index finger of the left hand, supporting it with the middle finger and tiger’s mouth for easy operation. To feed the wire, straighten the curved thumb and index finger (as shown in Figure b) to steadily feed the wire into the weld, then quickly bend them to reposition the grip (as shown in Figure a). Repeat to fill the weld.

Method 2: Hold the wire with the thumb, index, and middle fingers of the left hand for feeding, while using the ring and little fingers to control direction. Use arm and wrist movements to feed molten droplets at the wire tip into the weld pool. This method is commonly used for all-position welding.

6. TIG Welding Shielding Gases

Argon (Ar):

- Monatomic gas, colorless and odorless, 25% heavier than air—facilitates shielding.

- Accounts for ~1% of air, cost-effective.

- Welding purity requirement: 99.9~999%.

- Inert: Does not dissolve or react, preventing burnout of alloying elements in the weld (except evaporation).

- Low thermal conductivity, excellent combustion stability (voltage range: 8-15V).

Helium (He):

- Accounts for 0.0005% of air, lighter than air—poor shielding effect.

- High thermal conductivity, high arc temperature.

- Expensive.

- He+Ar: Used for welding thick plates, high thermal conductivity, and high melting point metals (double-layer shielding gas).

Argon-Helium (Ar+He):

- Adding He to Ar increases arc power and temperature.

Argon-Oxygen (Ar+O₂):

- Improves metal fluidity and arc stability. Low-oxygen mixtures for stainless steel welding; high-oxygen mixtures for carbon steel welding.

Argon-Hydrogen (Ar+H₂):

- 2-5% H₂ content results in smooth welds, prevents surface oxidation, increases arc temperature, and improves efficiency. Suitable for welding stainless steel, nickel-based alloys, and nickel-copper alloys.

Argon-Nitrogen (Ar+N₂):

Used for copper alloy welding. 2.5% N₂ is suitable for duplex stainless steel welding to maintain phase balance.

Typical Defects and Countermeasures in TIG Welding

| Defect Type | Causes | Solutions |

| Tungsten electrode contamination | Contact with weld pool or filler wire | Increase arc length (>3mm), replace the tungsten electrode |

| Porosity | Insufficient argon flow/air infiltration | Inspect gas pipe seals, increase flow rate by 20% |

| Tungsten inclusion | Excessive current or tungsten electrode melting | Use a thicker tungsten electrode, reduce current by 10-15% |

Key TIG Welding Operation Points

- Electrode Preparation: The tungsten electrode tip must be ground to a specific angle (e.g., 20° taper) to ensure arc concentration.

- Nozzle-to-Workpiece Distance: A larger distance degrades gas shielding, while an excessively small distance obstructs visibility and risks short-circuit between the tungsten electrode and weld pool (causing tungsten inclusion). The optimal distance is 8~14mm between the nozzle tip and the workpiece.

- Gas Pre-Purge/Post-Flow: Supply shielding gas 0.5~1s before ignition and delay shutdown for 2~5s after extinguishing the arc to protect high-temperature metals.

- Wire Feeding Technique: Feed the wire into the leading edge of the weld pool at a 15°~20° angle, avoiding contact with the tungsten electrode (to prevent contamination).

- Arc Voltage: TIG welding typically uses short arcs—an arc length less than 1.5 times the electrode diameter yields the best results.

Typical Application Scenarios of TIG Welding

- Aerospace: Welding of titanium alloy engine components and aluminum alloy housings (requires 100% non-destructive testing).

- Chemical Piping: Seal welding of stainless steel/nickel-based alloy pipes (high corrosion resistance requirements).

- Precision Manufacturing: Welding of thin sheets (0.5mm ultra-thin stainless steel) and nuclear reactor fuel tanks (zero defects required).

Summary of TIG Welding

TIG welding achieves precision welding through high-melting-point tungsten electrodes for arc heat transfer and argon gas for atmospheric isolation. Its core technologies include:

- High-frequency non-contact arc ignition to avoid contamination;

- DCEN/AC modes adapted to different materials;

- Pulse technology for precise heat input control.

It is suitable for scenarios requiring extremely high weld quality, such as aerospace pipelines and nuclear power plant seals.