With the rapid development of modern industry and infrastructure, steel pipes have become indispensable structural materials. Whether in construction projects or pipeline systems in the oil and gas industry, steel pipes play a crucial role. Faced with a wide variety of steel pipe types on the market, choosing the right steel pipe type has become a critical issue for engineers and procurement professionals. Welded steel pipes and seamless steel pipes, as two major mainstream products, each have unique advantages and application scenarios.

For example, spiral steel pipe applications are extensive, especially showing excellent performance in large-diameter pipeline transportation. With technological advances and diverse demands, the applications of steel pipes in construction continue to expand, covering more and more fields from foundational support to decorative structures. This article will provide an in-depth analysis of the basic types of steel pipes, combined with practical cases, and will detail the selection guidelines for steel pipes in the oil and gas industry, as well as the advantages and suitability of different types of steel pipes across industries, helping you make more informed and scientific choices!

Basic Classification of Steel Pipes

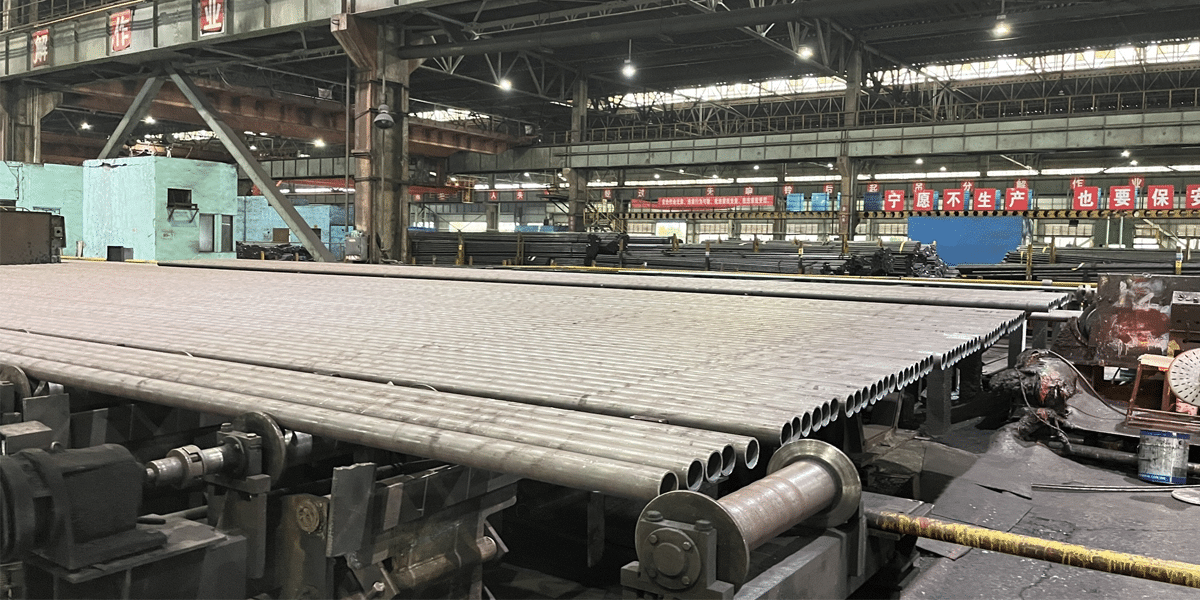

1. Seamless Steel Pipe — Detailed Introduction

Seamless steel pipe is one of the earliest and most widely used steel pipe types in industrial applications.

(1) Manufacturing Process

Seamless pipes are produced mainly through:

✅ Piercing: Heating a solid round billet to high temperature and piercing it with a piercing machine;

✅ Rolling: Reducing wall thickness and adjusting the outer diameter through multiple rolling steps;

✅ Sizing/Reducing: Ensuring dimensional accuracy via sizing mills;

✅ Cold Drawing/Cold Rolling (optional): Further improving surface finish and precision.

This process gives seamless pipes excellent mechanical performance and sealing properties.

(2) Performance Characteristics

Compared to other steel pipe types, seamless pipes offer significant advantages:

High strength and pressure resistance: Outstanding tensile and compressive properties;

High-temperature resistance: Suitable for high-temperature, high-pressure conditions;

Excellent sealing performance: No risk of leakage through weld seams;

High dimensional precision: Especially in cold-drawn products.

(3) Typical Applications

✅ Selection Guide in the Oil and Gas Industry:

Seamless pipes are widely used for high-pressure pipelines, oil casing, and drill pipes.

✅ Steel Pipes in Construction Applications:

Structural supports and load-bearing members in high-rise buildings.

✅ High-pressure boilers and heat exchangers.

✅ Precision mechanical manufacturing.

(4) Common Standards

GB/T 8163 (Seamless pipes for fluid transportation)

API 5L (Pipelines for oil and gas)

GB/T 5310 (Seamless pipes for high-pressure boilers)

2. Welded Steel Pipe — Detailed Introduction

Welded steel pipe is another crucial steel pipe type with high production efficiency and relatively low cost, widely used in construction, energy, and other industries.

(1) Manufacturing Process

Welded pipes are produced by forming steel plates or strips into a cylindrical shape and welding the seams.

According to the weld seam form, they are mainly divided into:

✅ Straight Seam Welded Pipe:

The weld seam runs longitudinally along the pipe;

Simple process and high production efficiency;

Common in small- and medium-diameter pipes.

✅ Spiral Welded Pipe (Spiral Pipe):

The steel strip is spirally wound to form the pipe;

Suitable for large-diameter pipes;

Good uniformity and excellent pressure-bearing capacity.

(2) Performance Characteristics

Outstanding cost-effectiveness: Lower production cost;

Wide range of dimensions: Spiral welded pipes are especially suitable for large diameters;

Weld inspection requirements: Non-destructive testing is necessary to ensure weld quality;

Reliable structural integrity: Modern welding processes meet most engineering needs.

(3) Typical Applications

✅ Spiral Steel Pipe Applications:

Long-distance pipelines for oil and gas transmission;

Large-scale water supply and drainage projects;

Port and bridge foundation piling.

✅ Straight Seam Welded Pipes:

Municipal water supply and heating pipelines;

Structural supports in construction;

General fluid transportation.

(4) Common Standards

GB/T 9711 (Pipelines for the petroleum and natural gas industries)

API 5L (Line pipes)

GB/T 3091 (Welded pipes for low-pressure fluid transport)

(5) Selection Tips

✅ For projects with moderate pressure requirements and large diameters, welded steel pipes are preferred;

✅ In scenarios demanding cost efficiency and convenient installation, welded pipes are an ideal choice;

✅ For long-distance or buried pipelines, spiral steel pipe applications are particularly suitable.

3. Galvanized Steel Pipe — Brief Introduction

✅ Surface coated with zinc layer for enhanced corrosion resistance;

✅ Common in building water supply, HVAC systems, scaffolding;

✅ Can be produced from welded or seamless base pipes.

4. Special-Purpose Steel Pipes — Brief Introduction

✅ Stainless Steel Pipe: Excellent corrosion and high-temperature resistance; used in chemical and food industries.

✅ Alloy Steel Pipe: Superior performance in high-temperature, high-pressure environments (e.g., boilers, power plants).

✅ Precision Steel Pipe: For high-precision mechanical parts.

Applications of Steel Pipes in Various Industries

Thanks to the diversity of steel pipe types, wide range of specifications, and excellent performance, steel pipes are widely used across multiple industries. Each application has different requirements for pipe performance, standards, and specifications, making how to choose the appropriate steel pipe type a key factor for project success.

1. Construction Industry (Steel Pipes in Construction Applications)

(1) Application Scenarios

✅ Structural pipes:

Steel frames for high-rise buildings (beams, columns, trusses)

Roof structures of stadiums and large venues

✅ Water supply and drainage pipelines:

Indoor and outdoor water supply systems

Firefighting pipelines

✅ HVAC piping systems:

Chilled/hot water pipes in central air conditioning

Steam and heating pipelines

✅ Scaffolding and support systems:

Temporary construction platforms

Formwork supports

(2) Selection Features

Structural use: primarily welded steel pipes (straight seam pipes) and large-diameter spiral welded pipes

Pressure-bearing fluid systems: certified welded or seamless steel pipes

Corrosive environments: galvanized steel pipes or anti-corrosion coated pipes

2. Oil and Gas Industry (Steel Pipes in the Oil and Gas Industry Selection Guide)

(1) Application Scenarios

✅ Transmission pipelines:

Long-distance pipelines for crude oil, refined oil, and natural gas

Gathering systems within stations

✅ Drilling equipment:

Drill pipes, oil casing pipes, screen pipes

✅ Offshore platforms:

Subsea pipelines

Structural support pipes

(2) Common Steel Pipe Types

Seamless steel pipes:

Used in high-pressure, high-temperature transmission lines, casing pipes

Spiral welded steel pipes:

Ideal for large-diameter long-distance pipelines (spiral steel pipe applications)

Straight seam welded pipes:

For medium- and short-distance gathering lines

(3) Selection Guide

✅ For high pressure and corrosive environments: seamless pipes are preferred

✅ For large-diameter transmission: spiral welded pipes offer better cost-performance

✅ For long-distance or buried pipelines: focus on anti-corrosion coatings and non-destructive testing

3. Power and Boiler Industry

(1) Application Scenarios

High-temperature, high-pressure steam pipelines in thermal power plants

Heat exchangers in nuclear power plants

Boiler heating surface pipes

(2) Selection Features

✅ Must use alloy seamless steel pipes for high temperature and pressure (e.g., 15CrMoG, 12Cr1MoVG)

✅ Strict dimensional accuracy

✅ High welding quality requirements

4. Machinery Manufacturing

(1) Application Scenarios

Hydraulic cylinder pipes

Automotive drive shafts and axles

Precision instrument components

(2) Common Types

✅ Cold-drawn seamless pipes for high precision

✅ Precision steel pipes for tight tolerance on roundness and wall thickness

5. Municipal Engineering

(1) Application Scenarios

Urban water supply networks

Drainage pipelines

Gas distribution pipelines

Bridge pile foundations

(2) Selection Features

✅ Spiral welded pipes for large-diameter transmission

✅ External anti-corrosion coatings (e.g., 3PE, epoxy coal tar enamel)

6. Chemical and Pharmaceutical Industry

(1) Application Scenarios

Chemical fluid transmission lines

Piping systems in highly corrosive environments

Precision heat exchangers

(2) Common Types

✅ Stainless steel pipes (304, 316L)

✅ Seamless steel pipes

✅ Lined steel pipes

Steel Pipe Selection Guide: How to Choose the Right Steel Pipe Type Based on Project Requirements

Facing various steel pipe types such as welded steel pipes, seamless steel pipes, and spiral steel pipe applications, scientifically selecting the most suitable steel pipe type directly affects the safety, economy, and long-term performance of the project.

1. Define the Project Application and Operating Conditions

Before choosing steel pipes, it is essential to fully understand the project’s operating requirements, including:

Medium being transported: water, oil, gas, steam, acidic/alkaline liquids, or slurry?

Working pressure: Is it a high-pressure system? Are there explosion or leakage risks?

Temperature range: Is high temperature (e.g., boilers) or low temperature (e.g., liquefied gas) resistance required?

Corrosive environment: Is there chemical corrosion, marine environment, or buried soil conditions?

Construction conditions: Is onsite welding feasible? What are the transportation and connection constraints?

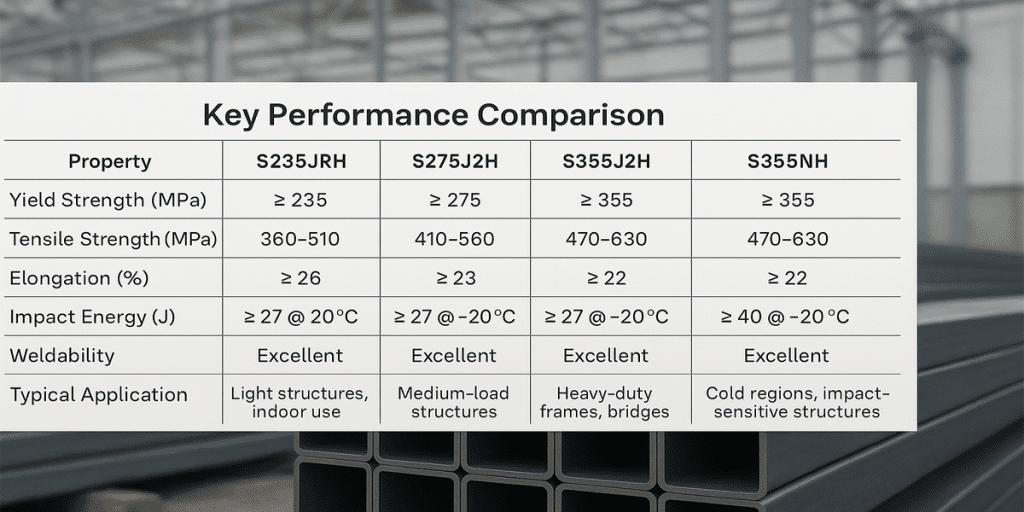

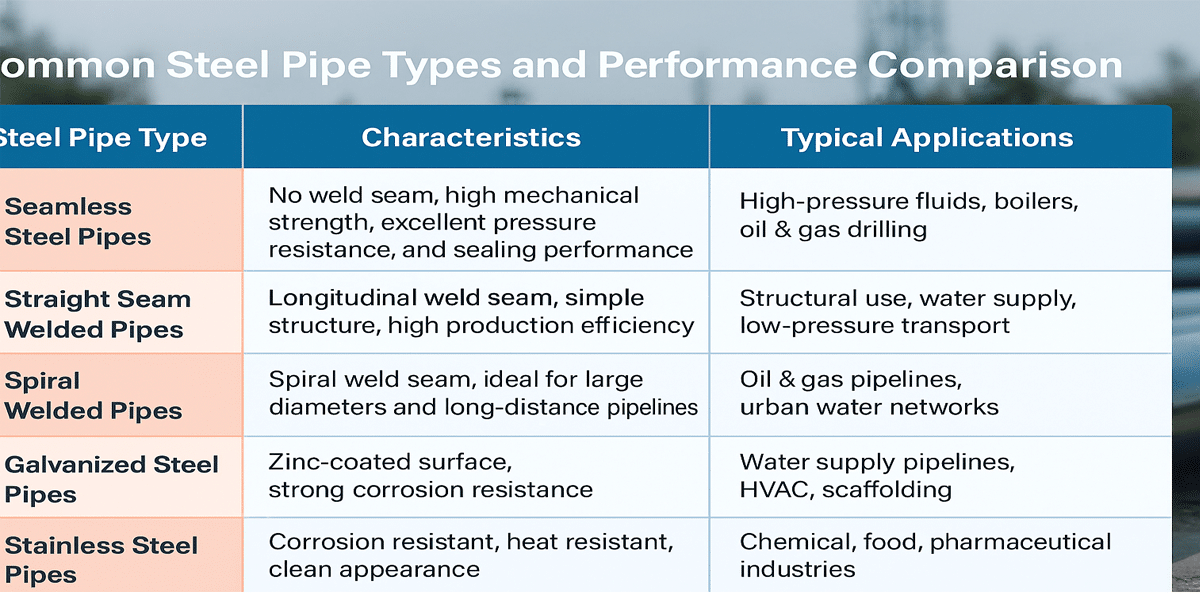

2. Understand Common Steel Pipe Types and Performance Comparison

Keyword example naturally integrated: “When considering how to choose the appropriate steel pipe type, it is important to match pipe selection to environmental conditions, balancing between welded and seamless steel pipes while assessing anti-corrosion requirements.”

3. Recommended Selection by Industry

1. Construction Industry

✅ Recommended types: Straight seam welded pipes, galvanized pipes, seamless structural pipes

✅ Typical applications: Building structural supports, fire protection pipelines, HVAC systems

✅ Key considerations: Load capacity, construction convenience, cost-effectiveness

2. Oil and Gas Industry

✅ Recommended types: Seamless pipes, spiral welded pipes

✅ Applications: Long-distance oil and gas pipelines, casing pipes, drill pipes

✅ Key considerations: High pressure, high temperature, corrosion resistance, nondestructive testing

3. Chemical & Pharmaceutical Industry

✅ Recommended types: Stainless steel pipes, seamless steel pipes

✅ Key points: Corrosion resistance, cleanliness, temperature resistance

4. Municipal Engineering (Water Conservancy, Gas)

✅ Recommended types: Spiral welded pipes, large-diameter straight seam welded pipes

✅ Typical applications: Water supply, drainage, gas pipelines, bridge pile foundations

✅ Key factors: Large diameter, anti-corrosion coatings, cost-performance ratio

4. Consider Cost and Construction Factors

Seamless steel pipes are generally more expensive but offer superior performance, ideal for critical or special working conditions

Welded steel pipes (especially spiral welded) offer better cost efficiency and suit large-volume projects

If onsite welding conditions are challenging, prioritize pipes with fewer joints or longer lengths

If welding capacity is limited, consider flange or threaded connection pipes

5. Summary of Selection Recommendations

Seamless steel pipes: High temperature, high pressure, tight sealing

Spiral welded steel pipes: Large diameter, long-distance transport

Welded steel pipes (straight seam): General structural support, low-pressure fluid transport

Stainless steel or coated pipes: Highly corrosive environment (chemical/marine)

Welded steel or galvanized pipes: Cost-sensitive, low pressure requirements

Steel pipes are a vital component in modern industry and infrastructure, and selecting the right type of steel pipe directly impacts the safety, cost-effectiveness, and service life of a project. This article analyzed the characteristics and applications of various steel pipe types, including seamless steel pipes, welded steel pipes, and spiral welded pipes, based on factors such as medium, pressure, temperature, and environmental conditions. Practical selection recommendations were provided for key industries like construction, oil & gas, chemical, and municipal engineering. In practice, scientifically evaluating project requirements and balancing performance, cost, and construction conditions are essential to choosing steel pipes that ensure efficient and safe operation. As technology advances and applications expand, mastering how to choose the appropriate steel pipe type will remain a critical skill in engineering design and procurement!