- 1. Overview of AS 1163 C250 and C350 Hollow Sections

- 2. Understanding Structural Steel Framing

- 3. Properties of AS 1163 C250 and C350 Hollow Sections

- 4. Suitability for Structural Steel Framing

- 5. Comparison with other steel grades

- 6. Compliance with building codes and standards

- 7. Case studies and examples

- 8. Design Considerations for Structural Steel Framing

- 9. References:

Are AS 1163:2016 C250 and C350 Hollow Sections Suitable for Structural Steel Framing?

The selection of appropriate steel grades is paramount to ensuring the safety and longevity of these projects. Among the available options, AS 1163 C250 and C350 hollow sections have attracted attention for their potential use in structural steel framing applications. The purpose of this article is to explore the suitability of these steels for such applications, taking into account their properties, industry standards and design considerations.

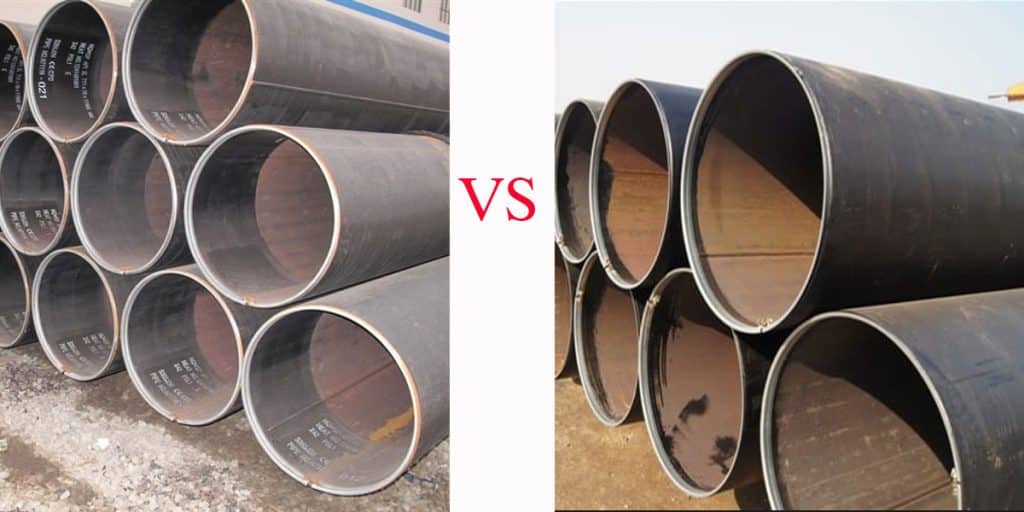

Overview of AS 1163 C250 and C350 Hollow Sections

AS 1163 C250 and C350 Hollow Sections are structural steel grades manufactured in accordance with Australian Standard AS 1163. These hollow sections, also known as Circular Hollow Sections (CHS) or Rectangular Hollow Sections (RHS), are seamless or welded tubular sections made from hot rolled or cold formed steel. The C250 and C350 designations indicate the basic yield strength of the steel, with C250 having a basic yield strength of 250 MPa and C350 having a basic yield strength of 350 MPa. These steel grades are generally used in various design and engineering applications due to their high strength-to-weight ratio and flexibility.

Understanding Structural Steel Framing

Structural steel framing is a development method that involves the use of steel members to make the essential load-bearing design of a structure or framework project. This framework is designed to support the weight of the structure itself, as well as any additional loads such as wind, snow and seismic forces. Selecting appropriate materials for the underlying steel framing is fundamental to ensuring the primary trustworthiness, wellbeing, and longevity of the project.

Properties of AS 1163 C250 and C350 Hollow Sections

AS 1163 C250 and C350 hollow sections have distinct mechanical properties that make them suitable for various structural applications. These higher strength properties allow the use of smaller cross-sections while still providing the required load-bearing capacity, resulting in potential material cost savings and a reduction in the overall weight of the structure.

Suitability for Structural Steel Framing

When evaluating the suitability of AS 1163 C250 and C350 hollow sections for structural steel framing, it is important to consider industry standards and guidelines. According to the Australian Steel Establishment (ASI), these steel grades are suitable for use in primary steel framing applications, provided the design and development follows key Australian guidelines and building codes. The high strength and durability of these hollow sections make them suitable for carrying significant loads and withstanding various environmental conditions.

Comparison with other steel grades

While AS 1163 C250 and C350 hollow sections offer advantages in terms of strength and material efficiency, it is important to compare them with other steel grades commonly used in structural steelwork. For example, lower strength grades such as AS 1163 C350L0 and C450L0 may be more cost effective for certain applications where design loads are lower. On the other hand, higher strength grades such as AS 1163 C450L0 and C550L0 may be preferred for applications with more stringent structural requirements or where weight optimization is critical.

Compliance with building codes and standards

When using AS 1163 C250 and C350 hollow sections for structural steelwork, it is important to comply with relevant building codes and standards. In Australia, the National Construction Code (NCC) and relevant Australian Standards such as AS 4100 (Steel Structures) provide guidelines and specifications for the design, fabrication and erection of steel structures. Compliance with these codes and standards ensures that steel structures meet the required safety, durability and performance criteria.

Case studies and examples

Real-world examples and case studies can provide valuable insight into the practical applications and benefits of using AS 1163 C250 and C350 hollow sections in structural steel framing projects. For example, these grades have been successfully used in the construction of high-rise buildings, industrial plants, bridges and other infrastructure projects. Case studies can highlight the design considerations, construction challenges and performance results of using these hollow sections, further demonstrating their suitability for structural steel framing applications.

Design Considerations for Structural Steel Framing

When designing structural steel framing using AS 1163 C250 or C350 hollow sections, several factors must be considered to optimize strength, stability and cost-effectiveness. These considerations include

– Load calculations and structural analysis to determine the required section sizes and steel grade

– Joint design and detailing to ensure proper load transfer and structural integrity

– Corrosion protection and durability measures for long-term performance

– Constructability and erection considerations for efficient erection and installation

– Compliance with applicable codes, standards, and project-specific requirements

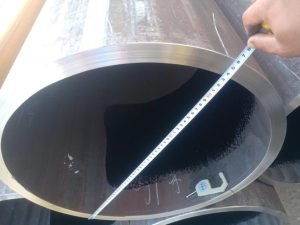

LONGMA produce and export AS 1163 C250 or C350 hollow sections, AS/NZS 1163 C350L0 steel pipes , size from NPS2 to NPS 56, Sch10-XXS. As one of China leading steel pipes manufacturers since 2003, certified by API 5L, ISO9001, ISO14001, FPC, LONGMA always supply high quality AS NZS 1163 grade C250, AS NZS 1163 grade C350l0 with full range pipe grades & pipe specifications. Contact by info@ilongma.com to get more information.

References:

- Australian Norm AS 1163 (2016), “Cold-framed primary steel empty segments.”

- Australian Steel Organization (ASI), “Plan Limit Tables for Underlying Steel.”

- Public Development Code (NCC) of Australia.

- Australian Norm AS 4100 (1998), “Steel Designs.”

- Trahair, N.S., Bradford, M.A., and Nethercot, D.A. (2008), “The Way of behaving and Plan of Steel Designs to AS 4100.”

- Hancock, G.J. (2003), “Plan of Cold-Shaped Steel Designs.”

- Gere, J.M., and Timoshenko, S.P. (1997), “Mechanics of Materials.”