AS1163 C350 RHS for both residential and commercial construction projects

AS1163 C350 RHS, or Australian Standard 1163 C350 Rectangular Hollow Section, is a type of structural steel that has gained significant popularity in the construction industry. Understanding the suitability of AS1163 C350 RHS for both residential and commercial construction is critical for builders, architects and developers to make informed decisions when selecting materials for their projects. This article aims to provide a comprehensive analysis of the applicability of AS1163 C350 RHS in both residential and commercial construction, exploring its properties, benefits and potential challenges.

AS1163 C350 RHS in Construction

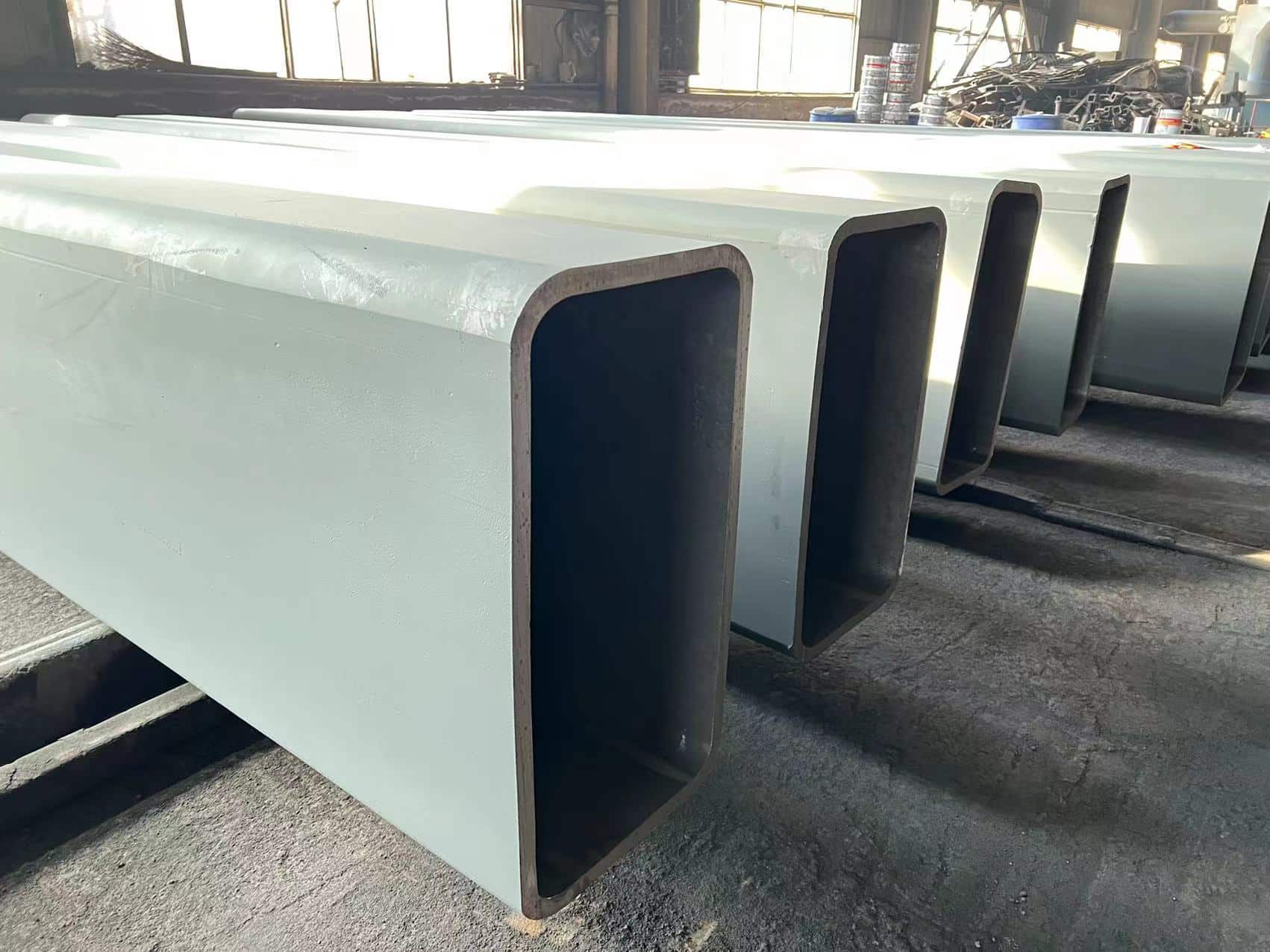

AS1163 C350 RHS is a type of hot rolled structural steel product that has a rectangular cross-section with a hollow interior. It is manufactured in accordance with Australian Standard AS1163, ensuring consistent quality and performance. The designation C350 refers to the minimum yield strength of 350 megapascals (MPa), making it a high strength material suitable for structural applications. AS1163 C350 RHS is commonly used in the construction of structural frames, columns, beams, trusses and other load-bearing elements in buildings.

Compared to other structural materials such as concrete or wood, AS1163 C350 RHS offers several advantages, including high strength-to-weight ratio, durability and ease of fabrication. Its hollow cross section and lightweight design make it efficient for transportation and installation, while maintaining excellent load-bearing capabilities.

Strength and Durability

One of the key benefits of the AS1163 C350 RHS is its exceptional strength and durability. With a minimum yield strength of 350 MPa, this material can withstand significant structural loads, making it suitable for both residential and commercial construction projects. Its high strength enables the design of slender and lightweight structures, reducing overall material usage and construction costs.

The durability of AS1163 C350 RHS is another critical factor that makes it a viable choice for long-lasting construction projects. When properly protected from corrosion, this material can withstand harsh environmental conditions, ensuring the longevity of the structures it supports.

Versatility in design

The AS1163 C350 RHS offers versatility in design, allowing architects and engineers to explore creative and innovative solutions for both residential and commercial projects. The rectangular shape of the hollow sections provides flexibility in orientation, allowing for unique architectural expressions and aesthetically pleasing designs.

In addition, the ability to fabricate AS1163 C350 RHS into various shapes and configurations through cutting, welding and bending techniques expands its applications in construction. This versatility enables the creation of intricate and complex structures to meet the diverse design requirements of residential homes, office buildings, retail spaces and other commercial facilities.

Cost Effectiveness

When considering the total cost of construction, the AS1163 C350 RHS can be a cost-effective choice for both residential and commercial projects. While the initial material cost may be higher than some alternatives, the long-term savings associated with its durability, strength and ease of installation can offset the upfront cost.

The lightweight nature of AS1163 C350 RHS can reduce transportation and handling costs, as well as the need for specialized equipment during installation. In addition, its high strength-to-weight ratio allows the use of smaller sections, minimizing material usage and associated costs.

In commercial construction projects where durability and longevity are paramount, the use of AS1163 C350 RHS can result in lower maintenance and repair costs over the life of the building, further contributing to its cost-effectiveness.

Standards Compliance

AS1163 C350 RHS is manufactured in accordance with Australian Standard AS1163, ensuring consistent quality and performance. This standard specifies the chemical composition, mechanical properties and dimensional tolerances for hot rolled structural steel hollow sections, giving builders and engineers confidence in the reliability of the material.

In addition to complying with the AS1163 standard, the use of AS1163 C350 RHS in construction projects must comply with applicable building codes and safety regulations. These codes and regulations are designed to ensure the structural integrity, safety and longevity of residential and commercial buildings to protect both occupants and the public.

By adhering to these standards and regulations, construction projects using the AS1163 C350 RHS can meet the necessary requirements for obtaining building permits and certifications, ensuring compliance with local and national guidelines.

Environmental Impact

In today’s construction industry, there is an increasing emphasis on sustainable and environmentally friendly practices. AS1163 C350 RHS can contribute to these efforts by offering several environmental benefits.

Firstly, steel is a highly recyclable material and the production of AS1163 C350 RHS often involves the use of recycled steel, reducing the demand for raw materials and minimizing the environmental impact associated with resource extraction.

In addition, the durability and longevity of AS1163 C350 RHS can reduce the need for frequent replacements and renovations, minimizing the generation of construction waste and the consumption of additional resources over the life of a building.

In addition, the lightweight nature of AS1163 C350 RHS can lead to reduced energy consumption during transportation and construction processes, contributing to lower carbon emissions and a smaller environmental footprint.

Case studies and examples

To illustrate the practical applications of AS1163 C350 RHS in both residential and commercial construction projects, several case studies and examples can be highlighted.

In the residential sector, AS1163 C350 RHS has been used extensively in the construction of single-family homes, apartment buildings and townhouses. Its versatility has enabled architects and builders to create unique and modern designs while ensuring structural integrity and safety. One notable example is the use of AS1163 C350 RHS in the construction of a contemporary residential complex in Sydney, where the material was used for load-bearing columns, beams and trusses, demonstrating its strength and aesthetic appeal.

In the commercial sector, AS 1163 C350 RHS/rectangular hollow section has been used in the construction of office buildings, shopping malls, industrial facilities and other large-scale projects. For example, a prominent commercial tower in Melbourne used AS1163 C350 RHS in its structural frame, taking advantage of the material’s high strength and durability to support the tall structure.

Challenges and considerations

While AS1163 C350 RHS offers numerous benefits for construction projects, it is important to recognize and address potential challenges and considerations associated with its use.

One of the primary challenges is the need for specialized fabrication equipment and skilled labor to cut, weld and assemble the hollow sections. This can increase labor costs and require additional training for construction workers.

In addition, the hollow nature of AS 1163 C350 rectangular hollow section may require special fire protection measures, such as the application of fire-resistant coatings or the use of insulation materials within the hollow sections, to ensure compliance with fire codes.

Corrosion protection is another important consideration when using AS1163 C350 RHS in building projects. While steel is generally durable, exposure to certain environmental conditions, such as moisture or salt water, can lead to corrosion over time. Appropriate surface treatments, coatings or galvanizing may be required to increase the material’s resistance to corrosion and ensure its longevity.

LONGMA produce and export AS 1163 C350 RHS/rectangular hollow section, AS/NZS 1163 C350L0 steel pipes , size from NPS2 to NPS 56, Sch10-XXS. As one of China leading steel pipes manufacturers since 2003, certified by API 5L, ISO9001, ISO14001, FPC, LONGMA always supply high quality AS NZS 1163 grade C250, AS NZS 1163 grade C350l0 with full range pipe grades & pipe specifications. Contact by info@ilongma.com to get more information.

References:

- Australian Standard AS1163 – Structural Steel Hollow Sections.

- Trahair, N. S., & Hancock, G. J. (2004). Steel Design Guides: Design of Cold-Formed Steel Structures. Australian Institute of Steel Construction.

- Gizejowski, M., & Salwón, J. (2020). Behaviour of Steel Hollow Sections in Compression. Materials, 13(18), 4087.

- Packer, J. A., & Henderson, J. E. (2003). Hollow Structural Section Connections and Trusses. Canadian Institute of Steel Construction.

- Dutta, D. (2020). Structural Design of Steel Hollow Sections. Journal of Structural Engineering, 46(5), 277-286.

- Yan, S., & Yang, B. (2018). Sustainable Structural Steel Design. In Proceedings of the Eighth International Conference on Sustainable Construction Materials and Technologies.

- Lawson, R. M., & Lim, J. B. P. (2016). Design of Structural Steel Hollow Section Members for Fire Resistance. Journal of Constructional Steel Research, 120, 1-14.

- Hancock, G. J., & Pekoz, T. (2011). Design of Cold-Formed Steel Structures. Australian Institute of Steel Construction.

- The Application of AS 1163 C350L0 CHS in Structural Area