In modern industrial and energy applications, choosing the right steel pipe grade is essential for ensuring safety, reliability, and long-term performance. ASTM A671 steel pipes are widely used in oil & gas, chemical, and power industries due to their strict mechanical properties, chemical composition, and welding standards. This article explores the key differences between ASTM A671 CC60, CC65, and CC70 grades, their applications, and how LONGMA ensures quality with advanced production and testing capabilities.

Overview of ASTM A671 Standard

ASTM A671 is the standard established by the American Society for Testing and Materials (ASTM) for Electric Fusion Welded (EFW) carbon steel pipes intended for pressure applications. The standard covers multiple grades, each designed for different strength and service conditions:

| Grade | Typical Material | Yield Strength (MPa) | Ultimate Tensile Strength (MPa) | Key Applications |

| CC60 | ASTM A516 Gr.60 | 240–310 | 415–550 | Medium to low-pressure pipelines |

| CC65 | ASTM A516 Gr.65 | 275–355 | 450–585 | Oil & gas distribution, chemical transport |

| CC70 | ASTM A516 Gr.70 | 310–415 | 485–620 | High-pressure, high-temperature systems |

Key Takeaways:

- CC60is ideal for low to medium-pressure systems with good weldability.

- CC65balances strength and toughness, commonly used in pipelines and offshore installations.

- CC70offers the highest strength and is suitable for high-pressure and demanding environments.

Mechanical Properties and Material Composition

Mechanical Properties Comparison

| Property | Test Standard | CC60 | CC65 | CC70 |

| Tensile Strength | ASTM A370 | 415–550 MPa | 450–585 MPa | 485–620 MPa |

| Yield Strength | ASTM A370 | ≥240 MPa | ≥275 MPa | ≥310 MPa |

| Elongation | ASTM A370 | ≥20% | ≥18% | ≥18% |

| Impact Energy | ASTM E23 | ≥27 J | ≥27 J | ≥30 J |

Chemical Composition (ASTM A671 Material)

| Element | Range (%) | Function |

| Carbon (C) | 0.24–0.30 | Increases strength and hardness |

| Manganese (Mn) | 0.70–1.35 | Enhances toughness and ductility |

| Silicon (Si) | 0.15–0.50 | Improves oxidation and corrosion resistance |

| Phosphorus (P) | ≤0.035 | Reduces brittleness |

| Sulfur (S) | ≤0.035 | Minimizes cracks and inclusions |

Note: Commonly used specifications such as ASTM A671 CC60 Class 22 and ASTM A671 CC65 CL22 undergo post-weld heat treatment (PWHT) to enhance toughness and minimize residual stress.

Welding Technology of ASTM A671 EFW Pipe

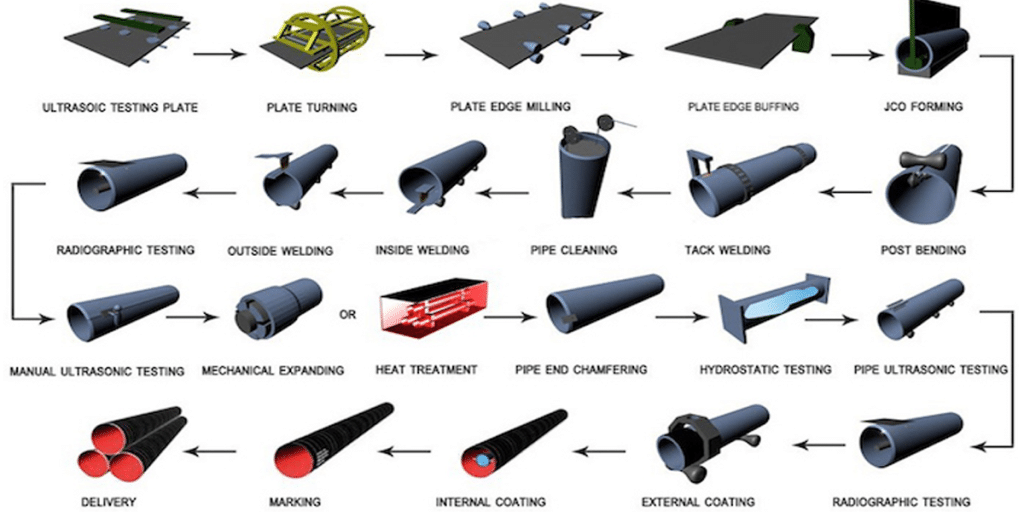

The EFW (Electric Fusion Welded) process is the core manufacturing method for ASTM A671 steel pipes. Steel plates are rolled into a cylindrical shape and welded using high-energy electric arcs. Key advantages include:

- Deep weld penetration– Reduces porosity and slag inclusions.

- Suitable for thick-wall pipes– Ideal for grades CC60, CC65, and CC70.

- Consistent weld quality– Automated controls maintain uniform weld thickness.

- Post-weld heat treatment compatibility– Enhances mechanical properties and reduces residual stress.

LONGMA’s production lines feature fully automated EFW welding machines with precise temperature control, ensuring each ASTM A671 EFW pipe meets ASTM specifications.

Inspection and Testing Methods

Quality assurance is critical for ASTM A671 steel pipes, especially for grades CC60, CC65, and CC70. Key testing methods include:

| Test | Standard | Purpose |

| Hydrostatic Test | ASTM A530 | Verify pressure resistance and leak-free performance |

| Radiographic Testing (RT) | ASTM E213 | Detect internal weld defects such as cracks or porosity |

| Ultrasonic Testing (UT) | ASTM E309 | Evaluate internal discontinuities and weld integrity |

| Tensile & Bend Test | ASTM E8/E8M | Confirm mechanical strength and ductility |

| Impact Test | ASTM E23 | Ensure toughness under low-temperature conditions |

| Chemical Analysis | ASTM E415 | Verify material composition and grade consistency |

LONGMA’s in-house laboratory is ISO/IEC 17025 certified, providing reliable Material Test Certificates (MTCs) for every batch.

Applications Across Industries

| Grade | Typical Application | Advantages |

| CC60 | Medium-pressure pipelines | Good weldability, stable performance |

| CC65 | Offshore oil & gas, chemical transport | Balanced strength and toughness |

| CC70 | High-pressure, high-temperature systems | High yield and tensile strength, durable under harsh conditions |

ASTM A671 EFW pipes are widely used in oil & gas pipelines, offshore risers, chemical plants, and thermal energy systems. Correct grade selection ensures safety, longevity, and minimal maintenance costs.

LONGMA Brand Advantages

- Over 20 years of experience in producing ASTM A671 material.

- Advanced EFW welding technologyensures consistent and defect-free welds.

- Complete range of grades CC60, CC65, CC70, customizable for thickness and length.

- Full compliance with international standards and third-party certification.

- Transparent testing and traceable MTC reports reduce procurement risks.

Conclusion

Selecting the correct ASTM A671 grade is critical for safe, efficient, and reliable engineering projects. Grades CC60, CC65, and CC70 offer different mechanical properties and applications, while ASTM A671 EFW pipes provide consistent performance, durability, and weld integrity.

LONGMA combines advanced manufacturing, strict quality control, and professional testing to deliver high-quality ASTM A671 steel pipes, helping clients complete projects safely and efficiently.