AS/NZS 1554 is a joint Australian and New Zealand standard applicable to welding and steel structure-related projects. It covers welding processes, quality control, and personnel certification for materials such as steel structures and aluminum alloys, and is widely used in construction, mining, manufacturing, and other fields to ensure structural safety and compliance.

Core Standards and Certification Requirements

The AS/NZS 1554 series is the core standard, consisting of several parts:

AS/NZS 1554.1: General Welding Structures

AS/NZS 1554.2: Welding of High-Strength Steels

AS/NZS 1554.3: Load-Bearing Welds for Wind Turbine Towers, etc.

AS/NZS 1554.4: Welding of Weathering Steels

AS/NZS 1554.5: Welding of High-Stress Loaded Steel Structures

AS/NZS 1554.6: Welding of Stainless Steels

AS/NZS 1554.7: Welding of Pipeline Structures

AS/NZS 1554.8: Welding of Aluminum Alloys

Certification Process

Welding Procedure Qualification:Verify the compliance of welding methods, including tensile testing, impact toughness testing, etc. The requirements for welding procedure qualification under Australian standards differ from those under European, American, and Chinese standards.

AS/NZS 1554.1 is limited to the welding of base metals with a specified minimum yield strength not exceeding 500MPa, and is applicable to welding methods such as shielded metal arc welding (SMAW), gas metal arc welding (GMAW), gas tungsten arc welding (GTAW), and flux-cored arc welding (FCAW).

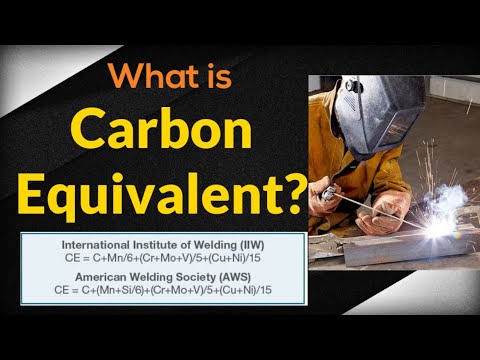

When domestic standards are adopted for raw materials and welding materials of export products, they shall be approved by the owner and specified in the contract. During welding procedure qualification, with reference to AS/NZS 1554.1-2014, welding materials shall follow the principle of strength matching with the steel type. The ER50-6 grade welding consumable is finally selected through the analysis of steel plate composition and calculation of carbon equivalent. The thickness coverage range of test pieces in AS/NZS 1554.1-2014 is larger than that in ISO 15614-1.

For full penetration butt welds and incomplete penetration butt welds:

The procedure qualification for single-sided welded single V-groove butt welds shall be valid for double V-groove butt welds and double-sided welded single V-groove butt welds.The procedure qualification for single-sided welded single U(J)-groove butt welds shall be valid for double U-groove butt welds and double-sided welded single U(J)-groove butt welds.

The procedure qualification for double V-groove butt welds shall be valid for double V-groove butt welds and double-sided welded single V-groove butt welds.The procedure qualification for double U-groove butt welds shall be valid for double U-groove butt welds and double-sided welded single U(J)-groove butt welds.

For fillet welds, the qualified fillet weld procedure using steel plate or steel pipe fillet welding processes is also applicable to fillet welds of steel plates and steel pipes.

Welding shall be carried out under the supervision of a welding supervisor employed by or under contract with the manufacturer. The welding supervisor shall ensure that all welding is performed in accordance with the requirements of the plan, specifications, any other documents, and this contract. A welding supervisor with at least three years of experience in manufacturing welded structures and holding an IWS, IWT, or IWE certificate issued by the International Institute of Welding (IIW) is deemed to have the qualification of a welding supervisor.

Welders shall possess appropriate qualifications to perform the required welding procedures. Welders meeting the requirements of standards such as AS1796, AS2980, AS/NZS3992, NZS4711, or ISO9606-1 are deemed to have welder qualifications.

Welding shall be strictly executed in accordance with the requirements of the pWPS (preliminary Welding Procedure Specification). All test specimens shall be numbered, and welders shall hold qualifications in accordance with ISO 9606-1.

During the welding procedure qualification process, materials shall be prepared and welding shall be performed in strict accordance with the pWPS. A qualified third-party international certification body shall be entrusted to witness the welding and heat treatment processes on-site, record welding parameters, retain heat treatment curves, and collect documents such as welder certificates and material certificates. After the test specimens pass non-destructive testing, macroscopic examination, hardness testing, and mechanical property testing, the third-party international certification body shall issue a qualified welding procedure qualification report (PQR).

Third-Party Audit:Conducted by organizations such as Weld Australia, and SCA certification is obtained upon passing the audit.

Application Fields and Material Specifications

1.Application Fields

Construction, bridges, pressure vessels, mining equipment, shipbuilding, oil and gas pipelines, etc.

2. Material Specifications

Steel shall comply with AS/NZS 3678.

Under AS/NZS 1554.1, the Australasian Certification Authority for Reinforcing and Structural Steels (ACRS) certification for structural steel typically covers the following requirements:

Chemical composition analysis: Conduct chemical composition analysis on structural steel materials to ensure they meet the composition ranges specified in the standard, including carbon content, sulfur content, phosphorus content, etc.

Mechanical property testing: Perform mechanical property tests on structural steel, including tests of tensile strength, yield strength, elongation, and other indicators to ensure they meet the mechanical property requirements specified in the standard.

Impact property testing: Conduct impact property tests on structural steel, such as energy absorption tests and Charpy V-notch impact tests, to evaluate its toughness at low temperatures.

Weldability testing: Carry out weldability tests on structural steel, including tensile tests and impact tests of welded joints, to assess the quality and performance of welded joints.

Microstructure analysis: Perform metallographic analysis on structural steel to observe its microstructure and grain size, and evaluate the effects of heat treatment and process treatment.

Surface quality inspection: Inspect the surface quality of structural steel, including the evaluation of surface flatness, surface cleanliness, surface defects, etc.

Dimensional inspection: Check the dimensions of structural steel to ensure they meet the dimensional requirements specified in the standard, including length, width, thickness, etc.

Other tests: Depending on the specific product and application, other tests may be required, such as corrosion resistance testing and heat treatment performance testing.

Through these tests, ACRS can evaluate the quality and performance of structural steel products to ensure they meet the requirements of AS/NZS 1554.1, thereby obtaining ACRS certification to prove their suitability for use in the construction and engineering fields.

Welding of aluminum alloys refers to AS/NZS 1664.1. Welding consumables such as 4043 and 5183 shall avoid high temperatures above 65°C.

Welding Symbols and Processes

Drawing symbols follow AS 1101.3, including basic symbols (such as butt welds, fillet welds) and supplementary symbols (such as field weld marks, contour symbols). Process requirements include joint design, edge preparation, and testing (such as bend tests, notch fracture tests).

Applicable Industries and Certification Bodies

1.Applicable Industries

Construction and civil engineering, mining equipment manufacturing, shipbuilding and marine engineering, oil and gas pipeline welding, etc.

2.Certification Bodies

Including third-party certification bodies such as Weld Australia, TWI Australia, Bureau Veritas, SGS, and Lloyd’s Register.

Comparison with Other Standards

1.Comparison with ISO 9606

AS/NZS 1554 is somewhat similar to ISO 9606 (international welder certification standard), but there are slight differences in test details.

2.Comparison with AWS D1.1

Compared with AWS D1.1 (American Welding Society structural steel standard), AS/NZS 1554 places more emphasis on compliance with building regulations in Australia and New Zealand.

Implementation and Quality Control

1.Quality Management System

Factories shall establish a sound quality management system (such as ISO 9001) to ensure that all links in the welding process strictly comply with standard requirements.

2.Welding Procedure Qualification (PQR)

Verify the welding procedure to ensure that the welding process can meet the strength and quality requirements of the structure.

3.Material Control

All materials used for welding must comply with relevant standards and obtain corresponding certifications. The chemical composition and mechanical properties of materials shall meet the design requirements.

4.Environmental Control

The environmental conditions during welding (such as temperature, humidity, wind speed, etc.) must comply with the provisions of the standard. For outdoor operations, measures shall be taken to prevent the impact of wind, rain, etc., on welding quality.

Inspection and Testing

1.Visual Inspection of Welds

Ensure that there are no obvious defects on the weld surface, such as cracks, porosity, slag inclusions, welding misalignment, etc.

2.Ultrasonic Testing (UT)

Used to detect internal weld defects such as porosity, cracks, and incomplete fusion.

3.Radiographic Testing (RT)

Adopted for critical welds to inspect internal defects.

4.Magnetic Particle Testing (MT) and Penetrant Testing (PT)

Applied to detect surface and near-surface cracks and other defects in welds.

5.Tensile Testing, Bend Testing, and Impact Toughness Testing

Verify the strength, ductility, and crack resistance of welded joints.