- 1. Image Characteristics of Common Welding Defects on Films

- 2. Comparative Analysis of Easily Confused Defects

- 3. Defect Evaluation in Standard Specifications

- 4. Defect Classification Standards

- 5. Differences in Defect Characteristics of Different Materials

- 6. Practical Application Suggestions

- 7. Future Development Trends of Welding Defect Radiographic

- 8. Summary of Welding Defects and Non-Destructive Testing Images

The performance of welding defects on radioscopic films is a key basis for welding quality evaluation. Various common welding defects have distinct image characteristics and corresponding standard specifications on the films.

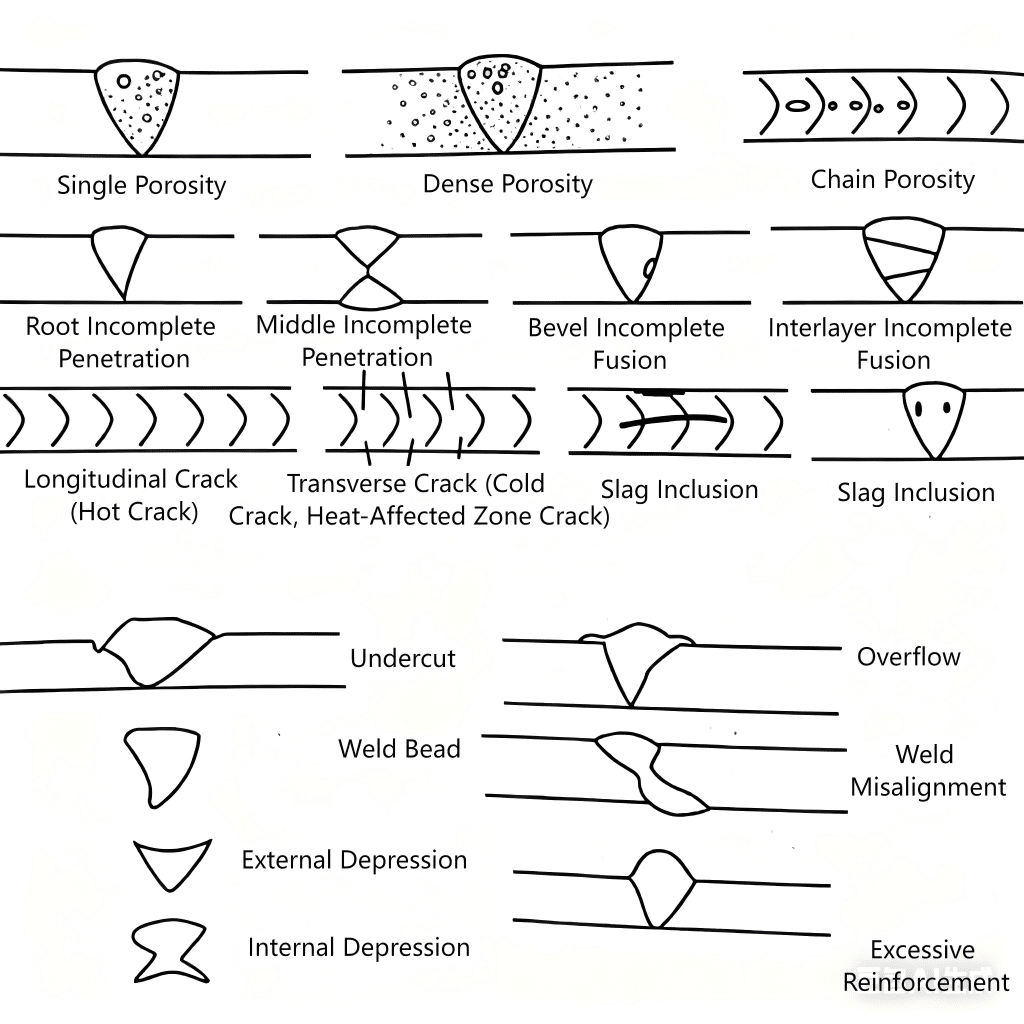

There are 18 typical defects, including uneven welds, root incomplete fusion, insufficient reinforcement, root weld bead, external undercut, internal undercut, root depression, burn-through, isolated slag inclusion, linear slag inclusion, internal incomplete fusion, inner-side incomplete fusion, porosity, chain porosity, bead inclusion, transverse crack, centerline crack, and root crack.

By systematically mastering the image characteristics and relevant standards of various defects, one can accurately interpret welding films and provide reliable basis for welding quality evaluation. In practical applications,comprehensive analysis should be conducted in combination with specific process conditions and material properties. The following will systematically introduce the film image characteristics, relevant standards and interpretation methods of various welding defects.

Image Characteristics of Common Welding Defects on Films

1.Porosity

Morphological characteristics: Appear as round or elliptical black spots on the film, with greater blackness in the center and gradual reduction towards the edges, and regular shape.

Classification: Can be divided into isolated porosity and chain porosity; chain porosity is distributed in clusters.

Spherical porosity: Round or elliptical black spots with high central blackness, gradually fading edges and clear contours. It can be divided into single, dense, chain and surface porosity.

Strip porosity: Parallel to the weld axis, with uniform and light blackness, rounded starting point and tapering end.

Oblique acicular porosity: Earthworm-like images with one rounded end and one pointed end, light and uniform blackness.

Typical performance: Single porosity has shallow and smooth edges with regular and clear contours; dense porosity is distributed in clusters.

Identification points:

- Single porosity has smooth and clear contours;

- dense porosity is clustered;

- chain porosity is arranged along the weld axis.

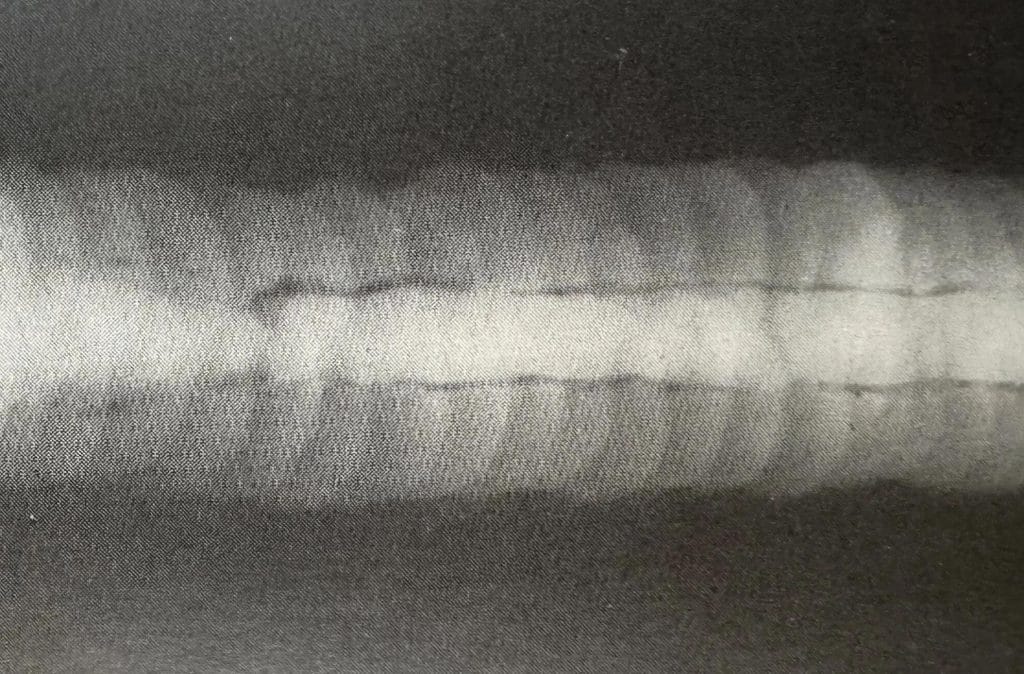

2.Crack

Morphological characteristics: Appear as thin black lines on the film with distinct contours, tapering ends and slightly thicker middle.

Specific performance: Thin black lines, slightly serrated and wavy fine lines, tapering ends, blackness gradually fading and disappearing to form a straight fine line with distinct contours, often tapering at both ends and slightly wider in the middle, possibly containing branched radioactive cracks with light blackness.

Identification points:

- Present in curved or straight lines.

- May be accompanied by filamentous shadow extension.

- Most harmful, all are Grade IV films.

Transverse crack:

Centerline crack:

Root crack:

3.Slag Inclusion

Morphological characteristics: Appear as dot-like or strip-like shapes of various forms on the film.

Specific performance: Images on the film are black spots, black strips or black blocks with irregular shapes, irregular blackness changes, unsmooth contours and some with edges and corners. They may occur anywhere in the weld, and the extension direction of strip slag inclusions is mostly parallel to the weld.

Dot-like slag inclusion: Uniform blackness, irregular boundaries with edges and corners.

Strip slag inclusion: Uneven blackness, usually thick strip-like with inconsistent width.

Identification points:

- Non-metallic slag inclusions appear as dark spots.

- Metallic slag inclusions (such as tungsten inclusion) appear as bright spots.

- Strip slag inclusions have inconsistent width and uneven blackness.

4.Tungsten Inclusion: White block-like images with clear contours.

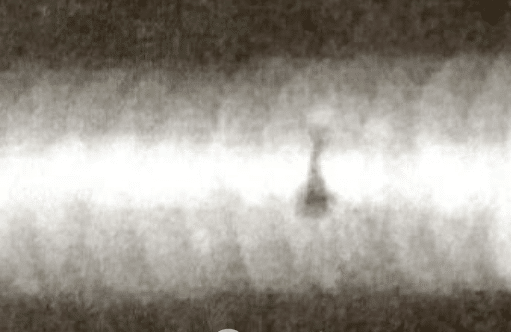

5.Incomplete Fusion

Classification: Bevel incomplete fusion and interlayer incomplete fusion.

Characteristics of bevel incomplete fusion:

Typical images are continuous or discontinuous black lines, with neat and straight contours and greater blackness on the side close to the base metal.

The contours of incomplete fusion images near the weld center may be regular or irregular, showing serrated block defects. Their position on the film is the projection position of the weld root.

Classification and characteristics:

Root incomplete fusion: Continuous or discontinuous black lines, with neat and straight contours and greater blackness on the side close to the base metal.

Bevel sidewall incomplete fusion: Black lines with inconsistent width and uneven blackness, neat contour on one side and irregular on the other.

Interlayer incomplete fusion: Block-like shadows with low blackness and irregular shapes.

Characteristics of interlayer incomplete fusion:Mostly flaky distributed between weld metal layers, with shallow shadows, uneven blackness, wider lines and irregular broken ends.

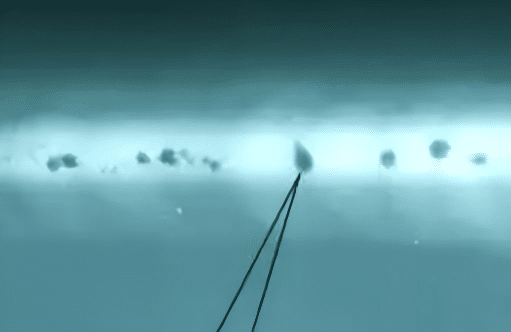

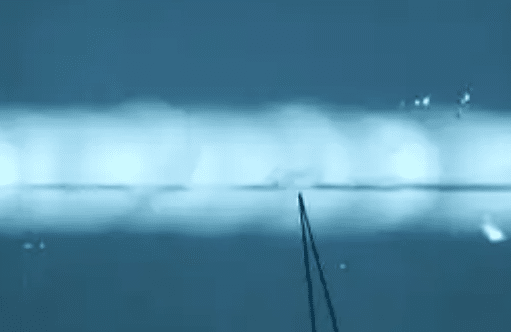

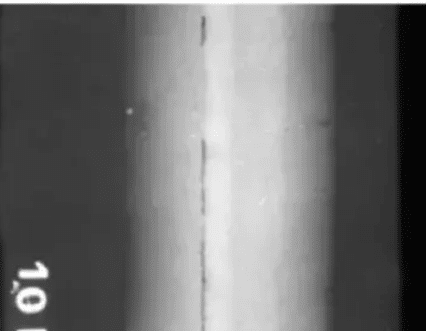

6.Incomplete Penetration

Classification: Root incomplete penetration, middle incomplete penetration and non-bevel incomplete penetration.

Characteristics of root incomplete penetration: Located in the middle of the weld, appearing as a straight black line, continuous or discontinuous strip-like or band-like, with width depending on the butt gap. The shadow has uniform

blackness and obvious contours.

Identification points:

- Width consistent with the bevel root face gap.

- Usually located in the middle of the weld.

- May penetrate the entire film.

Root incomplete penetration:

Middle incomplete penetration:

7.Uneven Welds

The two sides of the weld are uneven and skewed.

- The film image is obviously divided into two parts with strong and weak exposure.

- The welded joint has deviation, and the weld root is insufficiently filled with metal. The film image is obviously divided into two parts with strong and weak exposure. There is an opaque black line along the boundary of strong and weak exposure.

8.Insufficient Reinforcement

The weld surface sags or has pits, and the film image shows that the exposure density of the entire section of the weld is darker than that of the welded part.

9.Root Weld Bead

Excessive weld metal at the weld root. In the center of the image, there is a brighter part extending along the weld path, or individual round dots.

10.External Undercut and Internal Undercut

- The weld image has irregular black shadows. Its exposure density must be darker than that of the welded part.

- In the center of the weld image, along the root edge of the weld path, there are irregular long and narrow black shadows.

11.Root Depression

12.Burn-Through

Comparative Analysis of Easily Confused Defects

| Defect Type | Image Shape | Density Feature | Location Feature | Wheel Feature |

|---|---|---|---|---|

| Lack of Penetration | Thin straight dark line | Relatively uniform | Weld root area | Aligned on both sides |

| Lack of Fusion | Intermittent dark line | Non-uniform | Groove or layer gap | Aligned on one side |

| Crack | Irregular fissure-like line | Large variation | Any location | With branching |

| Linear Inclusion | Irregular stripe-like shape | Non-uniform | Any location | With edges |

Defect Evaluation in Standard Specifications

GB Standard System: Chinese National Standard. GB/T 3323-2019 is divided into four grades: I, II, III and IV. It is applicable to the weld inspection of steel, nickel, titanium and other materials, and is accelerating the alignment with

international standards.

NB/T 47013.2-2015: Specifies the technical grades (A, AB, B) for radiographic testing of pressure-bearing equipment; clarifies the testing requirements for different material and thickness ranges; systematically classifies and grades the quality of welded joint defects.

ISO Standard System: Formulated by the International Organization for Standardization (ISO), representing international general specifications. The latest versions are ISO 17636-1:2022 and ISO 5817:2023, applicable to the

inspection of fusion welded joints of metal materials, adopting three quality grades: B, C and D.

ASME BPVC Section V: Provides ultrasonic inspection methods for welds; includes requirements for calibration test blocks and sensitivity comparison test blocks; details the methods for measuring the length and height of defect signals.

ASTM Standard System: Standards of the American Society for Testing and Materials (ASTM), with ASTM E94/E94M as the core, adopting Grade I-IV evaluation. It emphasizes practicality and flexibility more, allowing some defects exceeding standard limits to be accepted through engineering evaluation, and provides standard guidelines for radioscopic inspection, including defect identification and evaluation methods.

EN Standard System: European standards take EN1090 and ISO3834 as the core framework, implementing a mandatory CE certification system, classifying steel structures into four grades: EXC1 to EXC4.

JIS Standard System: Japanese Industrial Standards are known for their rigor. JIS Z3104 attaches special importance to the fatigue performance evaluation of welded joints, usually with a safety factor 20-30% higher than

international standards.

Defect Classification and Acceptance Grades:

| Standard System | Defect Classification | Quality Grading Division | Typical Acceptance Requirements |

|---|---|---|---|

| ISO 5817:2023 | 6 major categories, 23 sub-types (cracks, porosity, etc.) | B (stringent), C (general), D (loose) | Grade B: Porosity diameter ≤ 0.2s/0.2A (max 3 mm) |

| ASTM E94/E94M | Cracks, porosity, lack of fusion, etc. | Level I–V | Crack length limitation is 15–20% stricter than ISO |

| GB/T 3323-2019 | Cracks, lack of fusion, incomplete penetration, etc. | I, II, III, IV | Grade II: Porosity diameter ≤ 1.6 mm |

| JIS Z3104-2021 | Includes weld structural abnormality classification | Grade 1–4 | Crack acceptance lower than ISO by approx. 30% |

| EN ISO 10675-1:2020 | Steel, aluminum, titanium alloy welds | Grade A–D | Consistent with ISO 5817, plus stricter requirements for pressure equipment |

Image Quality and Sensitivity Requirements

| Standard | Image Quality Requirements | Sensitivity Requirements | Special Provisions |

|---|---|---|---|

| ISO 17636-1:2022 | Double-wire image quality | Nearly fixed wire sensitivity | Requires image quality indicator (IQI) |

| ASTM E94/E94M | Linear weld image | Sensitivity 1–2T | Allows digital image acquisition and storage materials |

| GB/T 3323-2019 | Linear weld image | A-level 2–4T, B-level 1–2T | Refers to EN 462-1/2 standards |

| ASME BPVC V | Flat image | Level 1–1T to Level 4–4T | Usually uses 5 sensitivity grades |

Crack Detection Allowable Values Comparison

| Standard | Base Metal Thickness Range (mm) | Allowable Crack Size | Testing Method |

|---|---|---|---|

| ISO 5817:2023 | 0.5–100 | Grade B: Length ≤ 2 mm | RT / UT / PAUT |

| ASTM E399-2023 | – | Crack tip radius ≤ 0.25 mm ± 0.05 mm | Fracture toughness testing |

| ASME BPVC V 2023 | – | ΔK = 10⁴–7 mm/period | Fatigue crack growth testing |

| JIS Z3104-2021 | – | 30% stricter than ISO | Special ultrasonic flaw detection |

Defect Classification Standards

- GB/T 3323-2019 specifies the radiographic testing method and quality grading standard for welding joints of metal fusion welds.

Grade I: No incomplete fusion or cracks allowed;

Grade II: Incomplete fusion length ≤3mm;

Grade III: Incomplete fusion length ≤5mm;

Grade IV: Any incomplete fusion is unqualified.

- ISO 10675-1 Standard

This standard specifies the acceptance grades for non-destructive radiographic testing of welds, applicable to welded joints of steel, nickel, titanium and their alloys. The standard provides examples of defect area ratio and calculation methods for acceptable cumulative defect areas.

Differences in Defect Characteristics of Different Materials

- Carbon steel welds: Porosity is mostly regular round; incomplete fusion images have obvious blackness contrast; cracks are mostly straight.

- Stainless steel welds: Porosity may be finer and denser; incomplete fusion images may be more blurred; cracks may have more branches; due to the large linear expansion coefficient of stainless steel (about 1.5 times that of carbon steel), stress cracks are more likely to occur during cooling.

- Aluminum alloy welding:

- Porosity characteristics: Unobvious edge contours, regular round dots or chrysalis-like black shadows, with greater central blackness and smaller edge blackness. Porosity in automatic welding is larger than that in manual welding, round or oval with obvious edges.

- Special forms: May appear herringbone distribution (CO porosity) or tadpole-like (H₂ porosity).

Practical Application Suggestions

Film Evaluation Skills:

First confirm the film marks and four basic indicators; start observation from the fusion line; pay attention to the position and distribution characteristics of defects.

Defect Interpretation Skills:

- Observe blackness changes: Porosity has high central blackness and fading edges; incomplete fusion has greater blackness on one side; slag inclusion has uneven blackness.

- Analyze contour characteristics: Incomplete penetration is neat on both sides; cracks are serrated; slag inclusions have edges and corners.

- Position judgment: Root defects are in the middle of the weld; bevel incomplete fusion is at 1/2 position; interlayer incomplete fusion has uncertain positions.

- False defect identification: Developer crystals appear as star-shaped spots; intensifying screen scratches cause parallel stripes, which do not reappear in repeated exposure.

Common Misunderstandings:

- Confusion between incomplete penetration and incomplete fusion;

- misjudgment of surface defects and internal defects;

- distinction between false defects (such as IP board scratches) and real defects.

Future Development Trends of Welding Defect Radiographic

Testing Technology Artificial intelligence and deep learning are completely changing traditional radiographic testing technology and becoming the core driving force for future development. Deep learning-based automatic welding defect recognition systems have achieved industrial-grade applications, with major technological breakthroughs including:

Optimization of YOLO series algorithms: The improved YOLOv7 model achieves 56.8% mAP on the COCO dataset with a detection speed of 45FPS; YOLOv5 achieves an average recognition accuracy of 94.9% for single images in welding defect detection, with a processing time of only 19.58ms, meeting real-time requirements.

Application of U-Net++ network: The Dice coefficient reaches 0.94 in weld X-ray image segmentation, and transfer learning strategy improves the accuracy of small-sample (<500 images) training to 85%.

New detector technologies promote detection capabilities to break

| Technology Type | Performance Parameters | Application Advantages |

|---|---|---|

| Flexible X-ray Detector | 30 μm resolution, long-lasting luminescence | Enables curved-surface workpiece imaging; supports 360° full-angle scanning |

| Micro-focus X-ray Source | 1 μm resolution, 160 kV penetration capability | Detects micro-cracks in BGA package chips; suitable for complex structures |

| Quantum Sensing Technology | nT-level magnetic detection sensitivity | Diamond NV color-center magnetic sensors can detect early-stage micro-cracks |

Significant progress has been made in industrial CT real-time imaging systems:

The spatial resolution reaches (3.8+L/100)μm, and the maximum tube voltage of the microfocus X-ray source is 300kV. The detection speed is 300% higher than that of the traditional film method, and it can capture the thermal stress distortion trajectory during welding in real time.

Integrated AI algorithms realize automatic defect classification, with a detection rate of over 95% for volumetric defects such as porosity and slag inclusion.

Breakthroughs in miniaturization and low-dose technology:

The on-chip micro-undulator X-ray source developed by the Chinese Academy of Sciences has an equivalent period of 50 nanometers, enabling kiloelectron volt-level collimated X-rays.

Micro-radiation gamma-ray technology reduces the safety protection distance to within 1 meter, suitable for the weld inspection of thin-walled pipes with wall thickness ≤15mm.

The world’s first X/Y nuclear radiation dose detection chip is only the size of a button, with an operating temperature range of -20℃ to 50℃.

Multimodal non-destructive testing integration has become an industry consensus:

Integrate multiple NDT technologies in a single device and improve accuracy through comprehensive result analysis.

The platform integrating 3D profiler and thermal imager developed by rail vehicle manufacturing enterprises achieves a detection rate of 99.2% for composite defects in welds of high-speed rail bogies.

Two technical paths, feature-level fusion and decision-level fusion, develop in parallel, balancing detection comprehensiveness and computational efficiency.

ISO 9712:2025 strengthens personnel qualification certification, requiring Level 2 personnel to be capable of independently performing detection operations and preparing reports.

GB/T 3323-2019 stipulates that the radiographic detection sensitivity shall reach 2%, and ISO 17636-1:2022 requires the ultrasonic probe frequency range to be 1-10MHz.

GBZ 115-2023 Radiation Protection Standard for Low-energy Radiation Devices updates radiation protection requirements, with the annual effective dose limit for the public remaining at 1mSv.

- Existing Technical Bottlenecks:

Inadequate adaptability to complex working conditions: Temperatures above 500℃ cause sensor failure, and the acoustic impedance difference of steel/aluminum joints is up to 3 times.

Lack of data annotation: More than 70% of data in industrial sites are unannotated, and the spatiotemporal registration error of multi-source data exceeds 0.1mm.

Real-time requirement: The system needs to meet a delay of <200ms, and existing algorithms still face difficulties in deployment on edge devices.

Digital twin-driven detection: Constructing virtual weld models can improve prediction accuracy by 30%.

Quantum sensing technology: Applied to early micro-crack detection, breaking through traditional physical limits.

Materials genome engineering: Predicting the performance of welding materials through AI and optimizing process parameters.

Summary of Welding Defects and Non-Destructive Testing Images

In short, for welding defects and non-destructive testing images, it is necessary to remember the characteristics of the following 5 common defects on testing images, which helps to accurately judge the type and size of defects.

Porosity: Round/elliptical black shadows with high central blackness and gradually fading edges; porosity in automatic welding is mostly distributed in the center of the weld.

Slag inclusion: Irregular black shadows with distinct contours; metallic slag inclusions appear as bright spots, and non-metallic slag inclusions appear as dark spots.

Incomplete penetration: Thin straight black lines, neat on both sides, fixed at the weld root, with width corresponding to the root face gap.

Incomplete fusion: Divided into three types – root (single-sided neat black line), bevel (crescent-shaped black line), interlayer (irregular light black shadow).

Crack: Serrated thin black lines, wider in the middle and tapering at both ends, most harmful.