- 1. Green and Environmental Protection: Promoting Low-Carbon Transformation Development

- 2. Intelligent Manufacturing: Promoting Digitalization and Automation Upgrades

- 3. Product Upgrades: Moving Towards High Performance and Customization

- 4. Global Expansion and Enhancing Export Competitiveness

- 5. Addressing Uncertainty and Building Supply Chain Resilience

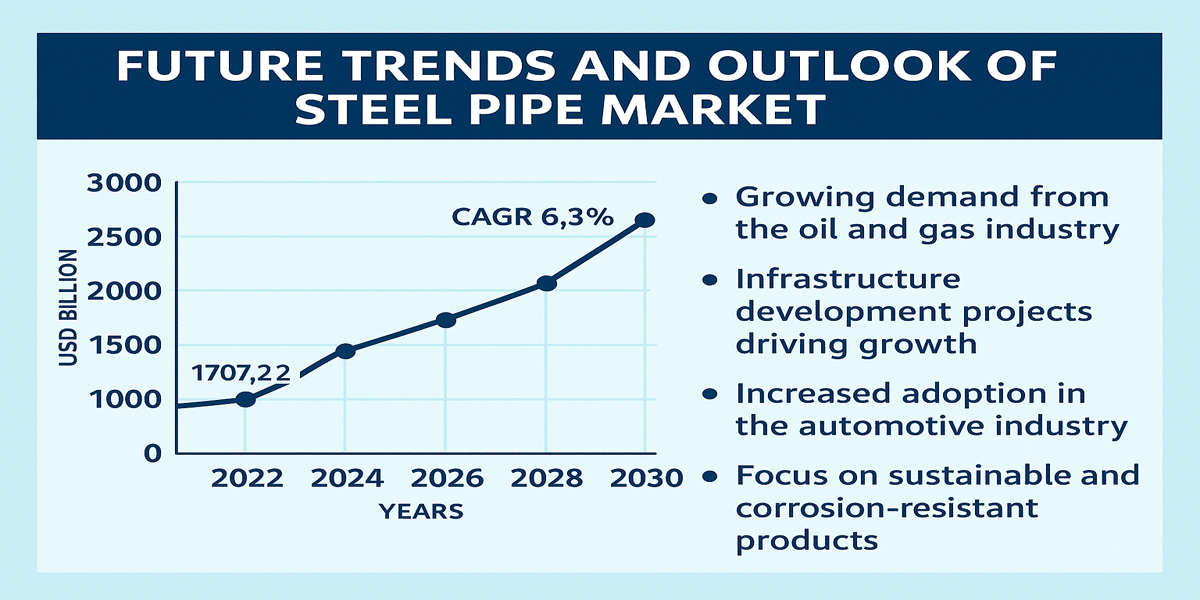

With the changing global market demands and increasingly strict environmental regulations, the steel pipe industry is undergoing a profound transformation. Steel pipe intelligent manufacturing and digitalized production are becoming the core driving forces for future development. By applying intelligent technologies, the industry will achieve more efficient and precise production methods. At the same time, green steel pipe production is becoming an inevitable choice for the future, and low-carbon steel pipe solutions will be a key factor in enhancing the competitiveness of enterprises. In the future, the steel pipe industry will continue to develop towards a more digital, intelligent, and environmentally friendly direction. So, how will the steel pipe industry respond to these changes? How can it seize the opportunities brought by future market trends? How can enterprises maintain competitiveness during this transformation?

Green and Environmental Protection: Promoting Low-Carbon Transformation Development

With the increasing global focus on environmental regulations and the trend towards green development, the steel pipe industry is facing unprecedented transformation pressures. The low-carbon transformation is not only an inevitable choice for the industry’s sustainable development but also a key measure in addressing climate change and reducing environmental pollution. The low-carbon transformation in the steel pipe industry will focus on the following aspects:

1. Application of Low-Carbon Smelting Technology: Low-carbon smelting technology is a crucial step in the steel pipe production process. By using new smelting processes, such as replacing traditional blast furnaces with electric arc furnaces (EAF), enterprises can significantly reduce carbon emissions. Additionally, some companies are exploring green hydrogen smelting technology, using hydrogen instead of traditional coal or natural gas to achieve even lower carbon emissions.

2. Optimizing Production Processes and Energy Management: Optimizing production processes is another key aspect of reducing carbon emissions. By improving energy efficiency, recycling waste heat, and enhancing the energy consumption of equipment, steel pipe enterprises can reduce energy waste and lower carbon emissions during production. At the same time, the introduction of intelligent energy management systems can monitor and adjust energy use in real-time, ensuring the most efficient energy consumption during production.

3. Growing Demand for Green Steel Pipe Products: As industries such as construction, oil and gas transportation, and environmental protection increasingly demand green products, low-carbon steel pipe products have become a new highlight in market competition. Especially in areas with stricter environmental requirements, low-carbon steel pipe solutions are gradually becoming the first choice. This not only helps enterprises tap into new markets but also promotes further application of green technologies.

4. Policy Support and Industry Standards Leading the Way: Government policies supporting low-carbon emissions and environmental protection will accelerate the low-carbon transformation of the steel pipe industry. For example, regions like the EU and China have introduced stringent emission standards, pushing steel pipe enterprises to accelerate the application of green production technologies. Meanwhile, the growing emphasis on green certification and environmental standards worldwide has opened up a broader market for low-carbon steel pipe products.

Intelligent Manufacturing: Promoting Digitalization and Automation Upgrades

With the continuous development of technology, intelligent manufacturing has become the core driving force for the future development of the steel pipe industry. The application of digitalization and automation technologies not only improves production efficiency but also enhances product quality, reduces costs, and drives the industry toward a higher level of transformation. By applying intelligent technologies, the steel pipe industry can not only increase the flexibility and precision of production but also achieve full-process digital management, driving a comprehensive upgrade of the industrial chain.

1. Introduction of Digital Production Management: With advancements in big data, cloud computing, and the Internet of Things, digital production management has become a key means for the steel pipe industry to improve production efficiency and precision. By monitoring production data in real-time, optimizing production processes, and conducting predictive maintenance, enterprises can effectively reduce downtime, lower production costs, and improve the overall quality of products.

2. Establishment of Automated Production Lines: The introduction of automated production lines is an important component of intelligent manufacturing in the steel pipe industry. Automated equipment can complete complex production tasks without relying on manual operations, improving production efficiency and reducing the possibility of human error. Through the combination of robots, automated equipment, and intelligent sensors, the production process can run more accurately, efficiently, and stably.

3. Intelligent Quality Control Systems: Quality control is a critical aspect of steel pipe production. Intelligent quality control systems, through automated inspection and real-time data analysis, can monitor the entire production process and provide rapid feedback. Using artificial intelligence algorithms and machine learning technologies, these systems can quickly detect and correct defects in production, ensuring consistent and stable product quality.

4. Interconnection of Production Equipment and Systems: In an intelligent manufacturing environment, the interconnection of various production equipment and management systems is crucial. By applying technologies such as the internet and cloud platforms, enterprises can effectively connect various production equipment, quality control systems, and supply chain management, creating a highly integrated information platform for intelligent control and optimization of the production process.

Product Upgrades: Moving Towards High Performance and Customization

With the continuous change in market demand and technological advancements, product upgrades in the steel pipe industry have become one of the key strategies for enterprises to maintain their competitive edge. By focusing on high performance and customization, steel pipe products can not only meet the growing demands for higher quality and specific functions but also help enterprises stand out in the fierce market competition.

1. Innovation of High-Performance Steel Pipe Products: High-performance steel pipe products typically feature enhanced corrosion resistance, high-temperature resistance, and compressive strength, making them suitable for high-demand industries such as oil and gas transportation, construction, and chemicals. By adopting advanced alloy materials and special coating technologies, enterprises can enhance the performance of steel pipes to meet the needs of extreme environments and harsh working conditions. High-performance steel pipes not only meet the growing demand in high-end markets but also improve the technical advantage of enterprises in key industries.

2. Growing Demand for Custom Products: As the demand for personalized solutions increases, more enterprises are focusing on producing customized steel pipe products. Customized products can be designed and manufactured according to specific customer needs, whether in size, material, or performance. The flexibility of customized products not only enhances customer satisfaction but also opens up new profit opportunities for steel pipe enterprises.

3. Combining Intelligent Manufacturing with Customization: The application of intelligent manufacturing technology provides strong support for the customization of steel pipe products. Through digital design, 3D printing, laser cutting, and other technologies, steel pipe enterprises can produce high-precision products tailored to customer specifications. Intelligent production lines can ensure both high production efficiency and the quality and accuracy of customized products, meeting customers’ high demands for product performance.

4. Market Segmentation and Expansion into High-End Applications: The steel pipe industry is gradually expanding into segmented markets and high-end applications. As industries continue to require more specialized and higher-performance steel pipe products, steel pipe enterprises must focus on product professionalization and high-end applications. For instance, in special industries such as oil and gas, aerospace, and aviation, steel pipe products need to possess higher resistance to corrosion, high temperatures, and greater strength. This requires steel pipe manufacturers to continually push for technological innovation to meet the needs of these high-end markets.

Global Expansion and Enhancing Export Competitiveness

With the accelerated pace of globalization, the steel pipe industry is facing broader market opportunities and challenges. To secure a favorable position in the global market, steel pipe enterprises not only need to strengthen their technological capabilities and production capacity but also enhance their export competitiveness through global expansion. By actively exploring overseas markets, optimizing product structures, and improving product quality, steel pipe enterprises can effectively increase export volumes and secure a strong foothold in the global market.

1. Exploring Overseas Markets and International Strategies: The globalization of the steel pipe industry is first reflected in actively exploring overseas markets. By entering emerging markets and tapping into mature markets, enterprises can increase their international sales share and mitigate the risks of relying on a single market. Expanding into different geographic regions, particularly high demand areas such as Asia, Europe, and North America, helps companies broaden their business scope, enhance brand influence, and strengthen their competitiveness in the international market.

2. Improving Product Quality and Technological Innovation: In global competition, product quality and technological innovation are key factors for steel pipe enterprises to enhance export competitiveness. High-quality steel pipe products can meet the strict requirements for performance, specifications, and environmental standards in different regions, while technological innovation enables companies to offer products that better align with market demands. By increasing the added value and technological content of products, enterprises can not only improve their market competitiveness but also establish a strong brand presence in international markets.

3. Optimizing Supply Chains and Logistics Management: In the process of global expansion, optimizing supply chains and logistics management is an essential part of enhancing export competitiveness. Steel pipe enterprises need to rationally position production bases, optimize raw material procurement, and distribution channels to reduce production and transportation costs. Additionally, by building an efficient global logistics system, companies can ensure fast delivery, improve customer satisfaction, and further enhance competitiveness in international markets.

4. Adapting to International Market Policies and Regulatory Requirements: The diversity of global markets requires steel pipe enterprises to understand and comply with the policies, standards, and regulations of different countries and regions. Whether it is product certification, environmental standards, trade policies, or responding to trade barriers, steel pipe enterprises need to be flexible in their approach, conduct thorough policy research, and manage compliance. By actively adapting to international market policies, enterprises can reduce trade risks and improve their chances of entering different national markets.

Addressing Uncertainty and Building Supply Chain Resilience

In a globalized and rapidly changing market environment, the steel pipe industry faces numerous uncertainties, including fluctuations in raw material prices, changes in international trade policies, global pandemics, and natural disasters. These factors can have a significant impact on the production and supply chain of steel pipe companies. Therefore, building a flexible and resilient supply chain has become a key strategy for steel pipe companies to cope with uncertainty and ensure stable production. The following strategies focus on key areas such as pricing, inventory, supply chain, and logistics to help the steel pipe industry address uncertainty and enhance supply chain resilience:

1. Flexibly Responding to Price Fluctuations: Fluctuations in raw material prices are one of the most uncertain factors in the steel pipe industry’s supply chain. To cope with the impact of price fluctuations, steel pipe companies can reduce price risks by diversifying supplier channels. Additionally, companies can lock in raw material prices through futures contracts or long-term agreements to maintain cost stability. When there is significant market fluctuation, companies should also adjust their product pricing strategy flexibly, adopting a phased pricing approach to avoid excessive pressure from sudden raw material price increases.

2. Optimizing Inventory Management: Optimizing inventory management is an important method to deal with supply chain uncertainty. Steel pipe companies can accurately forecast market demand and adjust inventory levels flexibly to ensure continued production in case of material shortages or supply chain disruptions. By introducing intelligent inventory management systems, companies can track inventory status in real-time, automatically replenish out-of-stock items, and reduce the risks of excess inventory. Furthermore, by adopting just-in-time (JIT) production models, companies can reduce capital tied up in inventory, improve liquidity, and avoid resource waste caused by inventory surplus.

3. Diversifying Supply Chain Structure: A diversified supply chain structure can effectively reduce the risks posed by reliance on a single supplier or production site. Steel pipe companies can establish stable partnerships with multiple suppliers to ensure that, in the event of a problem with one supplier, they can quickly source replacement materials from others. Additionally, international cooperation and the establishment of overseas production bases can further strengthen the supply chain’s ability to resist risks. In the face of emergencies such as natural disasters or pandemics, companies can quickly adjust production and supply strategies to ensure that the supply chain does not break down.

4. Enhancing Supply Chain Transparency and Information Sharing: Supply chain transparency and information sharing are crucial for timely response to supply chain disruptions and market changes. Steel pipe companies can introduce advanced Supply Chain Management (SCM) systems, Enterprise Resource Planning (ERP) systems, and Customer Relationship Management (CRM) systems to monitor the status of each supply chain link in real time. With system support, companies can quickly obtain feedback from suppliers, transportation providers, and customers, allowing them to adjust promptly and avoid unnecessary delays and losses. Maintaining open and transparent communication with suppliers and customers also helps form a collaborative approach in times of crisis, enabling the rapid restoration of supply chain stability.

5. Optimizing Logistics Management and Improving Delivery Capabilities: Logistics management plays a critical role in the steel pipe supply chain. Companies should plan transportation methods and routes reasonably to reduce risks and costs during transportation. Steel pipe products typically require long-distance transportation, and using different transportation modes (such as sea, rail, or road) may encounter delays, damages, and other issues. Therefore, selecting reliable logistics partners is essential. Intelligent logistics systems can help companies track shipments in real-time, optimize transportation plans, and ensure timely delivery of goods. Additionally, in logistics management, steel pipe companies should focus on controlling transportation costs by improving efficiency and optimizing route designs to further reduce costs and enhance the overall supply chain response capability.

Facing the challenges brought by the ever-changing market environment and globalization, the steel pipe industry is evolving towards greater intelligence, sustainability, and globalization. In the process of addressing uncertainty and enhancing supply chain resilience, steel pipe companies must keep pace with the times, innovate actively, and ensure they stand out in the fierce market competition. The future belongs to those who can flexibly respond to market changes, possess robust supply chain resilience, and continuously drive technological advancements. Let us pay attention to the development trends of the steel pipe industry and together embrace the challenges and opportunities of the future!

If you have any insights or thoughts on the future development of the steel pipe industry, feel free to leave a comment below. If you found this article helpful, please don’t forget to share it with more colleagues and friends, so that more people can stay updated on the latest dynamics and trends in the steel pipe industry!