In today’s globalized market, structural pipes, as a core material for various construction, infrastructure, and industrial projects, have always been a key focus in terms of compliance. Especially in the European market, with environmental and safety standards continuously rising, quality control and certification of products have become crucial. For manufacturers, ensuring that their products meet the EN 10219 standard and obtain CE certification is not only a prerequisite for entering the EU market, but also a key step in maintaining brand reputation and minimizing legal risks. As EU steel pipe standards continue to evolve, the compliance of structural pipes has become a fundamental indicator of product quality and reliability. This article will explore how to assess whether structural pipes comply with CE certification requirements through the EN 10219 standard and help businesses effectively navigate the challenges of the European market!

What is the EN 10219 standard?

EN 10219 is a European standard that mainly deals with the technical requirements for cold-formed welded steel pipes and hot-formed welded steel pipes. This standard is specifically applicable to steel pipes used in structural and engineering applications. It defines the dimensions, shapes, mechanical properties, testing methods, and the requirements for the raw materials used in the production of steel pipes.

The detailed content of EN 10219 includes the following aspects:

Scope:

EN 10219 applies to welded steel pipes that are either cold-formed or hot-formed, typically used in construction, structural, and engineering projects such as bridges, building frameworks, pipelines, etc.

Classification of Steel Pipes:

Based on the manufacturing method, EN 10219 is divided into two main categories:

Cold-formed welded steel pipes (EN 10219-1): Applicable to pipes produced by cold rolling, cold drawing, or cold bending.

Hot-formed welded steel pipes (EN 10219-2): Applicable to pipes produced by hot rolling or hot extrusion.

Material Requirements:

EN 10219 specifies the chemical composition and mechanical properties of the raw materials used in the production of steel pipes. Common materials include carbon steel, low alloy steel, etc., which must exhibit adequate strength, toughness, and corrosion resistance.

Dimensions and Tolerances:

The standard provides detailed requirements for the external diameter, wall thickness, length, and tolerances of the steel pipes. It defines the tolerance ranges for different pipe sizes to ensure consistency and precision in the manufacturing process.

Mechanical Properties:

The standard requires steel pipes to have certain tensile strength, yield strength, and elongation under specified conditions. It also requires pipes to be able to withstand certain impact toughness and compressive strength, meeting the safety demands for structural applications.

Quality Control and Inspection:

EN 10219 emphasizes the importance of quality control during the manufacturing process, requiring necessary inspections such as visual checks, dimensional measurements, mechanical property testing, and non-destructive testing (e.g., X-ray or ultrasound tests). Inspection reports must document the performance data of the pipes and comply with the standards.

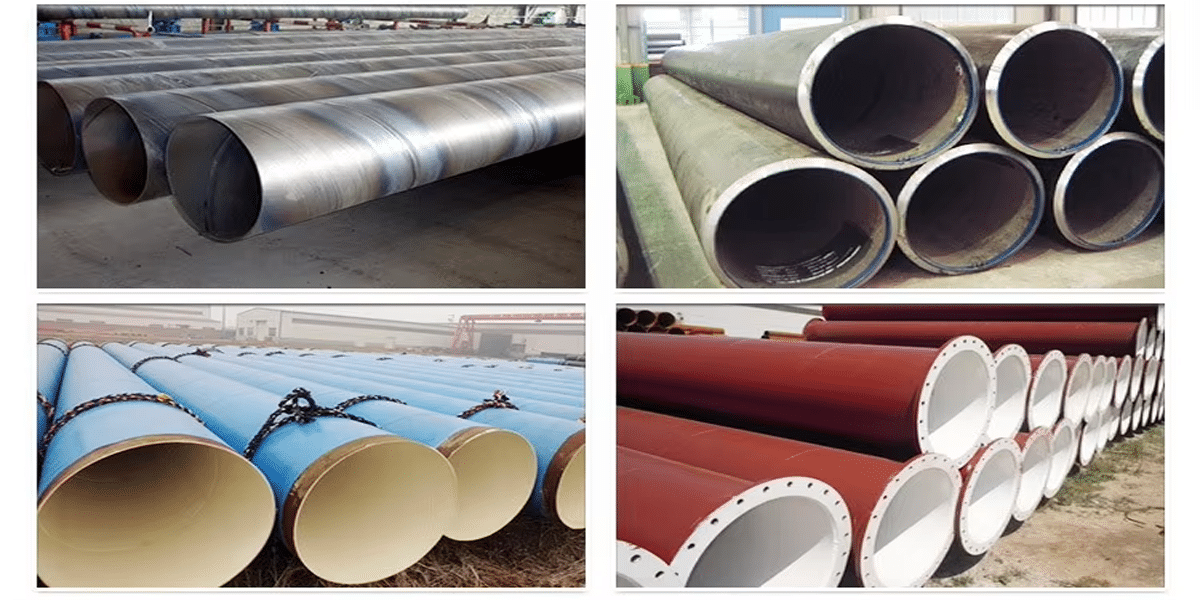

Surface Treatment:

The standard specifies the surface quality of steel pipes, which must undergo proper surface treatment to prevent rusting or corrosion. Common surface treatments include galvanizing or painting.

Adaptability:

EN 10219 is designed not only for steel pipe manufacturers but also for engineers, contractors, and other stakeholders, ensuring the standardization, compatibility, and applicability of the pipes.

What is CE Certification?

CE Certification (CE Marking) stands for “Conformité Européenne,” meaning “European Conformity” in French. It is a mandatory conformity marking system established by the European Union to ensure that products meet EU requirements related to safety, health, environmental protection, and consumer protection. Any product falling under specific EU directives or regulations must bear the CE mark in order to be legally sold within the EU and EEA (European Economic Area).

The CE mark:

Represents the manufacturer’s declaration of conformity with applicable EU legislation.

Acts as a passport for products to circulate freely in the EU/EEA market.

✅ What Products Require CE Certification?

CE certification applies to a wide range of products, including but not limited to:

Construction products (e.g., structural steel pipes, windows, concrete elements)

Electrical and electronic equipment

Machinery

Pressure equipment

Toys, PPE, medical devices, and more

For structural steel pipes (such as those manufactured according to EN 10219), the applicable regulation is the Construction Products Regulation (CPR – EU No. 305/2011).

✅ What Does EU Regulatory Compliance Include?

To obtain CE certification, a product must meet various EU compliance requirements, such as:

1. Compliance with Harmonized European Standards (e.g., EN standards)

For structural pipes, this includes standards like EN 10219 (for cold-formed welded structural tubes) or EN 1090 (for structural components), which ensure performance, consistency, and safety.

2. Technical Documentation

Manufacturers must create and maintain a comprehensive technical file, which includes:

Product description and intended use

Material data and drawings

Manufacturing processes and quality control plans

Inspection and test reports

Risk assessment

Conformity assessment records

3. Conformity Assessment Procedure

Depending on the product category and risk level, manufacturers must follow an appropriate conformity assessment procedure. In some cases, a Notified Body must perform audits, inspections, or testing.

4. EU Declaration of Performance / Conformity (DoP / DoC)

The manufacturer must issue a formal declaration stating that the product meets all applicable EU directives and standards. For structural products, this is typically a Declaration of Performance (DoP) under the CPR.

5. Affixing the CE Marking

The CE mark must be visibly affixed to the product, accompanied by identification details such as the manufacturer’s name, the relevant standard number, and possibly the Notified Body number.

Factory Production Control (FPC): Core Role in Certification

✅ What is Factory Production Control (FPC)?

Factory Production Control (FPC) refers to a systematic quality control system established within a manufacturing plant to ensure that all products consistently meet technical specifications and standard requirements. FPC covers the entire production process, from raw material procurement, manufacturing processes, equipment management, product testing, personnel training, to final product inspections.

It is a way for manufacturers to demonstrate to the European Union that their products have repeatability and consistency, and it is a crucial step in achieving CE certification and compliance with standards such as EN 1090 or EN 10219.

✅ Key Components and Essential Aspects of FPC

A comprehensive FPC system should include the following key elements:

1. Raw Material Control

All raw materials must be sourced from approved suppliers and come with material certification (e.g., performance reports, batch numbers for steel).

Establish procedures for incoming raw material inspection to ensure compliance with standards like EN 10219-1.

2. Production Process Control

Define control parameters for each production step (e.g., welding parameters, cold-forming precision, tolerance requirements).

Record data and operator information for all critical processes to ensure traceability.

3. Equipment Maintenance and Calibration

All equipment affecting product quality (e.g., welding machines, measurement tools, NDT equipment) must be regularly maintained and calibrated.

Maintenance records and responsible personnel must be documented.

4. Product Inspection and Testing

Includes dimensional measurement, visual inspection, mechanical performance testing (tensile strength, impact toughness), and non-destructive testing (e.g., ultrasonic or X-ray).

Define inspection frequency and acceptance criteria.

Inspection results must be recorded and archived to ensure compliance with EN standards like EN 10219.

5. Non-Conforming Product Control

Clearly identify, segregate, and handle non-conforming products.

Implement corrective and preventive actions to avoid recurrence of issues.

6. Personnel Training

All personnel involved in quality processes must be trained and qualified (e.g., certified welders, inspectors).

Regular quality and standard training must be provided.

7. Internal Audits and Continuous Improvement

Conduct regular internal quality audits to identify improvement areas.

Management must review the FPC system during management reviews to ensure effective operation.

✅ Why is FPC the Core of CE Certification?

1. Supports Product Consistency

CE certification is not about certifying a “single product” but about assessing the manufacturer’s ability to consistently produce products that meet the standards. FPC ensures that products are consistently manufactured to meet these standards.

2. A Mandatory Condition

According to standards like EN 1090-1 (CE certification for structural components) or EN 10219 (for structural steel pipes), the product’s ability to obtain the CE mark largely depends on whether an FPC system is established and effectively implemented.

3. Focus of Notified Body Audits

During the certification process, EU-authorized Notified Bodies will focus on reviewing the FPC system to confirm that the manufacturer truly has the capability to control quality.

How to Determine Whether EN 10219 Steel Pipes Meet CE Compliance?

To determine whether EN 10219 steel pipes meet CE compliance, it is necessary to ensure they meet the relevant regulations of the European market, particularly the Construction Products Regulation (CPR) and the technical requirements of the EN 10219 standard. The key points for determining compliance include the following:

1. Ensure Compliance with EN 10219 Standard

EN 10219 is the standard for cold-formed welded structural steel pipes, and the pipes must meet the following requirements:

Dimensions and Tolerances: The external diameter, wall thickness, and tolerances of the steel pipe must meet the specific requirements outlined in EN 10219.

Material Properties: The material of the steel pipe must meet the chemical composition and mechanical property requirements in the standard to ensure the pipe meets the design load-bearing capacity.

Welding Quality: The steel pipes must be welded using processes that meet the standard’s quality requirements, ensuring the structural safety of the welds.

2. Adherence to Construction Products Regulation (CPR)

For steel pipes used in construction, EN 10219 steel pipes must comply with EU Construction Products Regulation (CPR, EU No. 305/2011). Specific requirements include:

Declaration of Performance (DoP): The manufacturer must provide a Declaration of Performance (DoP), listing all technical parameters and performance data of the steel pipe, such as tensile strength, corrosion resistance, etc.

Conformity Assessment: A conformity assessment process (e.g., type testing or third-party inspection) is required to confirm that the steel pipe meets all technical standards and regulatory requirements.

3. Implement a Factory Production Control (FPC) System

To ensure CE compliance, manufacturers must implement a Factory Production Control (FPC) system, which includes:

Raw Material Control: Ensuring all raw materials used in production meet the requirements of EN 10219, with reliable sources and guaranteed quality.

Production Process Control: Controlling key processes like welding and cold-forming to ensure that the steel pipes’ dimensions, wall thickness, and weld quality meet the standard.

Inspection and Testing: Regularly testing the pipes for dimensions, mechanical properties, and weld quality to ensure each batch complies with EN 10219.

Personnel Qualifications: Ensuring all personnel involved in production and inspection are properly trained and capable of implementing the standards.

Records and Reporting: Maintaining detailed records of the production process to ensure compliance and for future audits.

4. Type Testing and Audits by Notified Bodies

Notified Bodies play a critical role in the CE certification process. Their involvement includes:

Type Testing: Notified bodies perform type testing on the steel pipes to confirm compliance with the EN 10219 standard and to ensure their safety and quality.

Factory Audits: Notified bodies audit the manufacturer’s factory production control (FPC) system to ensure it meets the standard requirements.

5. Provide Compliance Documents and CE Marking

Once the steel pipe meets all the requirements, the manufacturer must provide relevant compliance documents and affix the CE marking:

EU Conformity Declaration (DoC): This is the manufacturer’s declaration that the steel pipe meets the CPR and relevant EN 10219 standards.

Declaration of Performance (DoP): The manufacturer provides a performance declaration, specifying the technical data and performance characteristics of the steel pipe to ensure its safe use in construction or structural applications.

6. Key Additional Requirements: EN 1090-1 Certification and EN 10204 3.1 Material Test Report

In the framework of CE compliance, two important requirements are EN 1090-1 certification and EN 10204 3.1 Material Test Report, both of which are crucial for the compliance and market acceptance of structural steel pipes.

EN 1090-1 Certification:

EN 1090-1 certification is required when steel pipes are used in construction structures, particularly if they are used as load-bearing structural components. This certification ensures the steel pipe meets the Construction Products Regulation (CPR) and has been assessed by a Notified Body.

For steel pipes used in construction and structural engineering, obtaining EN 1090-1 certification is crucial for CE compliance. This certification involves ensuring the welding quality and structural safety, ensuring the pipes are reliable for long-term use.

EN 10204 3.1 Material Test Report:

EN 10204 3.1 Material Test Report is an official document provided by the material supplier that certifies the steel used meets the required standards for chemical composition and mechanical properties.

For structural steel pipes, providing the 3.1 report ensures the materials used meet EN 10219 or other relevant standards. This report is a key document to ensure the pipe meets performance and safety standards for load-bearing applications.

This report is essential for many construction projects and engineering contracts, especially when the pipes are used for load-bearing or structural applications, as it ensures product quality and compliance.

7. Ongoing Quality Control and Improvement

CE compliance is an ongoing process, not a one-time task. Therefore, manufacturers must regularly perform quality control and internal audits to maintain consistency and quality of their products. Manufacturers must:

Conduct Regular Audits: Through internal and external audits, ensure the production process continues to meet EN 10219 and CPR requirements.

Corrective Actions: When issues are found, corrective actions must be taken to ensure that steel pipes continue to meet the quality standards and avoid market and legal risks.

Compliance Verification Recommendations for Project Purchasers

Ensuring compliance in project procurement is critical, especially for construction, structural engineering, or projects involving the European market and CE certification. For purchasers, verifying that materials, equipment, or services meet regulatory requirements helps avoid compliance risks and ensures long-term safety and quality.

Below are key compliance verification recommendations for project purchasers:

1. Verify Supplier’s Compliance Certifications

Purchasers should verify whether suppliers hold relevant compliance certifications. For EN 10219 steel pipes, key certifications to check include:

CE Certification: Confirm that the supplier’s steel pipes meet EU market requirements and the Construction Products Regulation (CPR).

EN 1090-1 Certification: For steel pipes used as structural components, purchasers should verify if suppliers have EN 1090-1 certification to ensure structural safety.

ISO 9001: Check if the supplier has a quality management system certification to ensure stable production and product quality.

2. Request Necessary Compliance Documents from Suppliers

Purchasers should require suppliers to provide relevant documents proving product compliance for verification:

EU Declaration of Conformity (DoC): A formal declaration by the supplier that the product complies with CE certification and applicable EN standards.

Declaration of Performance (DoP): Especially in construction and structural projects, suppliers should provide a DoP detailing key technical parameters of the steel pipes, such as tensile strength and corrosion resistance.

EN 10204 3.1 Material Test Report: Request the 3.1 report proving that the steel material complies with EN 10219.

Type Test Reports: If third-party verification is required, ask for type test reports confirming the product passed relevant compliance tests.

3. Evaluate Supplier’s Factory Production Control (FPC) System

Purchasers should assess the supplier’s FPC system to ensure their production processes meet industry standards:

Factory Audits: Confirm whether the supplier’s production facilities have been audited by a Notified Body, ensuring compliance with production, quality control, and testing standards.

Quality Management System: Ensure the supplier has an established and continuously improving quality management system, with ISO 9001 certification often being a key indicator.

4. Verify Notified Body Credentials

For structural materials like steel pipes, purchasers should ensure compliance documents have been issued by qualified Notified Bodies:

Notified Body Accreditation: Confirm that compliance documents provided by suppliers are issued by accredited Notified Bodies, guaranteeing valid CE certification.

Audit Reports from Notified Bodies: When in doubt, request the notified body’s audit reports to further verify product compliance.

5. Perform On-Site Quality Inspection and Sampling Tests

Even if suppliers provide compliant documents, purchasers should conduct on-site quality checks and sampling tests to ensure product quality and compliance:

On-Site Sampling and Testing: Conduct dimensional, performance, and material tests on samples taken from delivered products to confirm conformity with design and standards.

Supplier Site Inspection: Perform factory visits to inspect production processes, capabilities, and equipment condition to ensure consistent compliant production.

6. Supply Chain Management and Continuous Monitoring

Purchasers should establish ongoing monitoring mechanisms to ensure suppliers maintain compliance throughout the project:

Regular Supervision and Inspections: Maintain regular communication and periodic inspections of suppliers to ensure ongoing compliance and quality control.

Contractual Compliance Clauses: Clearly define compliance requirements and quality standards in contracts, requiring suppliers to provide compliance evidence and reports.

7. Assess Supplier’s Emergency Response and Corrective Actions

Purchasers should evaluate suppliers’ ability to respond to and resolve compliance issues effectively:

Supplier Emergency Plans: Confirm whether suppliers have emergency response plans and can promptly address quality or compliance issues.

Issue Resolution History: Request records of past issues and resolutions to assess the supplier’s effectiveness and timeliness in handling quality problems.

Common Compliance Issues and Solutions

In project procurement, especially in industries involving EN 10219 steel pipes, CE certification, and EU steel pipe standards, the following are typical compliance issues and corresponding solutions:

1. Lack of Complete CE Certification Documents

Issue: The supplier fails to provide complete CE certification documents, such as the EU Declaration of Conformity (DoC) or Declaration of Performance (DoP).

Solution:

The purchaser should strictly require suppliers to provide complete CE certification-related documents.

Conduct a supplier qualification review to ensure they hold legitimate certification credentials.

Avoid procuring uncertified products to prevent potential regulatory penalties.

2. Absence of EN 1090-1 Certification

Issue: Structural steel pipes or components lack EN 1090-1 certification, preventing the product from legally entering the EU market.

Solution:

Confirm if the supplier has EN 1090-1 certification, especially for products used as load-bearing structural components.

If not certified, help the supplier establish production controls and testing processes to meet EN 1090-1 standards.

Choose suppliers who already hold EN 1090-1 certification to ensure compliance.

3. Missing EN 10204 3.1 Material Test Report

Issue: When procuring steel materials, the supplier fails to provide the material test report, making it impossible to confirm if the steel meets EN 10219 standards.

Solution:

Clearly request suppliers to provide the EN 10204 3.1 Material Test Report during procurement.

Conduct third-party testing on the materials to verify the authenticity of the report and material compliance.

Include material testing and report submission requirements in the procurement contract.

4. Inadequate Factory Production Control (FPC) System

Issue: The supplier lacks an effective production control system, leading to product quality fluctuations and difficulty ensuring compliance.

Solution:

The purchaser should assess the supplier’s FPC system to ensure it has been audited by a Notified Body.

Assist the supplier in establishing and improving the FPC to implement standardized production and strict quality control.

Conduct regular quality audits and supervision of the supplier’s processes.

5. Insufficient Notified Body Certification and Audits

Issue: The supplier’s certification documents are issued by unrecognized bodies, or there are no audit reports from notified bodies.

Solution:

The purchaser should verify the credentials of the Notified Body and ensure it is an EU-recognized body.

Require the supplier to provide audit reports from the Notified Body to confirm the certification process was legitimate.

Avoid accepting non-official or counterfeit compliance documents.

6. Missing Product Marking and Traceability Information

Issue: Products are not marked with the CE logo, or they lack traceability information such as production batch numbers.

Solution:

The purchaser should verify the product marking to ensure the CE mark is clear and compliant.

Require suppliers to establish a product traceability system to ensure that each batch can be traced back to its origin.

Clearly define marking and traceability requirements in the contract.

7. Lax On-Site Testing and Acceptance

Issue: The purchaser overlooks on-site sampling tests, allowing non-compliant products to enter the supply chain.

Solution:

Implement strict on-site testing and acceptance procedures for procured products.

Conduct sampling and testing of key performance indicators, and engage third-party testing agencies as needed.

Address any issues found and request corrective actions from the supplier.

8. Loose Supply Chain Management and Lack of Ongoing Compliance Monitoring

Issue: The purchaser does not establish an ongoing compliance monitoring system for suppliers, leading to product quality and compliance issues.

Solution:

Establish a comprehensive supply chain management system, clearly defining the compliance responsibilities of the supplier.

Set up regular inspection, communication, and training mechanisms to ensure compliance awareness throughout the procurement process.

Include compliance clauses in the procurement contract to bind the supplier to continuous compliance obligations.

9. Supplier’s Emergency Response and Corrective Actions Are Inadequate

Issue: The supplier is unable to respond effectively or take corrective actions when non-compliance or quality issues are identified.

Solution:

Verify whether the supplier has an emergency response plan in place and can address quality or compliance issues promptly.

Request records of past issue resolution to evaluate the supplier’s ability to resolve problems quickly and effectively.

Include corrective action plans and response timelines in the contract for more accountability.

Ensuring compliance is key to the success of project procurement. Whether it’s steel pipes, structural components, or other materials, purchasers should rigorously verify suppliers’ qualifications, certification documents, and production control systems. Regular reviews, on-site inspections, and continuous oversight can effectively reduce compliance risks, ensuring the safety and quality of the project. Proper compliance verification not only helps avoid regulatory risks but also enhances the long-term stability and credibility of the project. Compliance is the safest guarantee!