In the global market of structural steel pipes, two international standards are widely used: EN 10219 and AS/NZS 1163. The former is mainly adopted in Europe and large-scale international projects, while the latter is prevalent in Australia, New Zealand, and surrounding regions. For developers, contractors, and procurement managers, understanding the key differences between these standards helps in selecting the most suitable structural steel pipes for the project. LONGMA, as a professional manufacturer of ERW/LSAW round steel pipes, has in-depth knowledge and practical experience with both standards.

Comparison of Steel Grades

| Item | EN 10219 | AS/NZS 1163 |

| Common steel grades | S235JRH, S275J2H, S355J2H | C250L0, C350L0, C450L0 |

| Yield strength (MPa) | S235JRH ≥ 235; S355J2H ≥ 355 | C250 ≥ 250; C450 ≥ 450 |

| Impact toughness requirements | J0, J2 indicate impact resistance at 0°C or -20°C | L0 indicates impact resistance at 0°C |

The suffix “H” in EN 10219 refers to structural use with guaranteed impact toughness. In AS/NZS 1163, classes like L0 indicate toughness levels. EN 10219 provides more flexibility in specifying impact characteristics, making it suitable for low-temperature conditions.

Comparison of Applications

EN 10219 steel tubesare widely used in:

- Steel construction projects (e.g., airports, stadiums)

- Wind turbine towers, bridge structures

- Support frames for industrial equipment

AS/NZS 1163 tubesare mainly used in:

- Residential and industrial buildings in Australia and New Zealand

- Port facilities, mining structures

- Agricultural machinery and support structures

If your project is aligned with Europe or Belt and Road countries, EN 10219 offers broader compatibility. For projects within Australia or where local compliance is required, AS/NZS 1163 is the mandatory choice.

Comparison of Manufacturing Processes and Testing

| Item | EN 10219 | AS/NZS 1163 |

| Forming process | Cold-formed + high-frequency welding (ERW) or submerged arc welding (LSAW) | High-frequency welding (ERW) |

| Heat treatment | May be heat-treated to meet “H” category | Usually supplied as non-annealed |

| Testing procedures | Chemical, mechanical, dimensional control, impact test, NDT, weld inspection | Chemical, mechanical control, weld inspection, flattening/expansion test |

| Certification requirements | EN 10204 3.1 or 3.2 | Third-party inspection (e.g., SGS) for AS compliance |

EN 10219 involves more systematic and rigorous testing, particularly for low-temperature toughness and weld joint NDT.

Usage in International Projects with Examples

EN 10219 usage examples:

- Pipeline structures in Belt and Road projects (Central Asia)

- S355J2H pipes for wind towers in European projects

- Various national prefabricated building projects in China

AS/NZS 1163 usage examples:

- Metro rail support structures in Sydney

- Structural columns in New Zealand infrastructure

- Coastal facility upgrades in Papua New Guinea

Globally, EN 10219 is more widespread across Asia, Europe, and Africa, while AS/NZS 1163 dominates in Australia and the South Pacific.

How to Choose the Right Steel Pipe Standard?

- For projects in Europe, the Middle East, Africa, or those requiring ISO/EN standard compatibility: choose EN 10219.

- For projects in Australia, New Zealand, Oceania, or where AS certificationis required: choose AS/NZS 1163.

- For China-based or export-diverse projects, EN 10219 is generally preferred due to its international recognition and broader applicability.

Why choose LONGMA pipes?

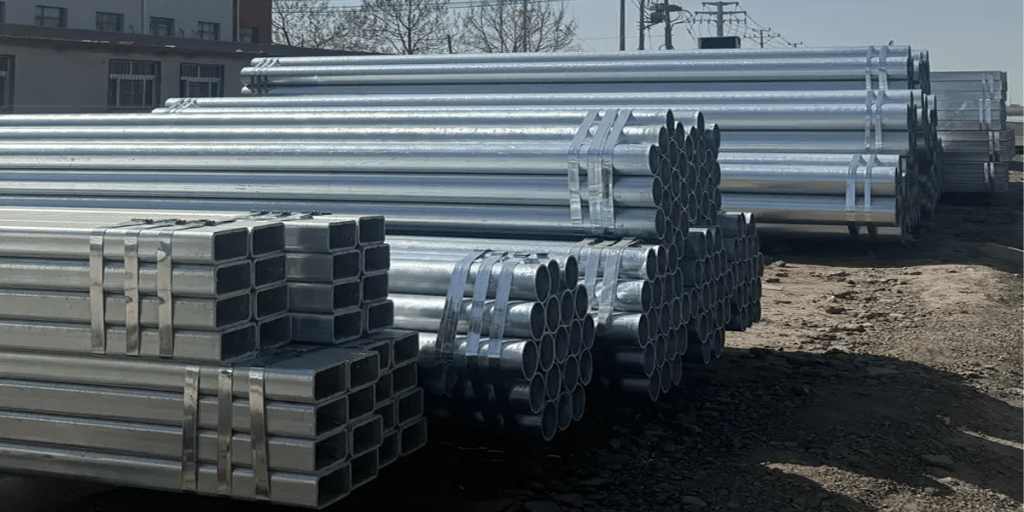

LONGMA is a structural steel pipe manufacturer based in Hebei, China, specializing in ERW and LSAW round pipes complying with EN 10219 and AS/NZS 1163. Advantages include:

- Full certification: EN 10204 3.1 provided, complying with EN 10219 series

- Product variety: Inventory from S235JRH to S355J2H

- Strict quality control: Every batch undergoes ultrasonic testing, impact tests, dimensional checks, and more

- Export expertise: Long-term partnerships with clients in Europe, the Middle East, Australia, etc.

- Fast delivery: Proximity to ports ensures timely shipment

- Custom production: Tailored to client requirements in size and test content

- Professional support: Technical assistance before and after sales

Both EN 10219 and AS/NZS 1163 have unique strengths. The choice should be based on project location, regulatory requirements, and material properties. As an experienced structural pipe manufacturer, LONGMA offers quality products and technical support that meet either standard, making it a reliable partner for your international projects.