In today’s highly competitive global infrastructure market, ASTM A671 steel pipes have become a trusted choice for high-pressure and high-temperature applications, especially in power plants, refineries, and long-distance oil and gas transmission systems. With over two decades of manufacturing expertise, LONGMA is committed to producing ASTM A671 EFW pipes that meet international standards and deliver exceptional reliability.

This article provides an in-depth look into the entire production and quality assurance process of ASTM A671 steel pipes—from raw steel selection to final inspection—and explains why LONGMA’s internal laboratory and strict quality control system ensure consistent excellence.

Understanding ASTM A671 Standard

The ASTM A671 standard specifies electric fusion welded (EFW) carbon steel pipes designed for atmospheric and lower temperature services. These pipes are manufactured from pressure vessel quality plates, such as ASTM A516 Gr.60 or Gr.65, ensuring superior weld integrity and mechanical properties.

Common Grades:

| Grade | Class | Typical Material | Key Application |

| ASTM A671 CC60 | Class 22 | A516 Gr.60 | Low-temperature pipelines |

| ASTM A671 CC65 | Class 22 | A516 Gr.65 | High-pressure steam lines |

| ASTM A671 CC70 | Class 12 | A516 Gr.70 | Power and refinery systems |

Each class number (e.g., Class 12, Class 22) represents different levels of heat treatment and testing requirements. For example, ASTM A671 CC65 Class 22 pipes are normalized and subjected to impact tests to guarantee toughness and long-term performance under pressure.

Raw Material Inspection and Plate Selection

The journey of an ASTM A671 EFW pipe begins with the careful selection of steel plates that comply with ASTM A516 or equivalent pressure vessel specifications. LONGMA’s engineers perform multiple tests, including:

- Ultrasonic flaw detection (ASTM A435/A578)

- Chemical composition analysis (ASTM E415)

- Mechanical testing for yield and tensile strength

By ensuring the incoming plates meet strict standards, LONGMA minimizes weld defects and ensures optimal structural performance for its ASTM A671 pipes.

Precision Manufacturing and Welding Process

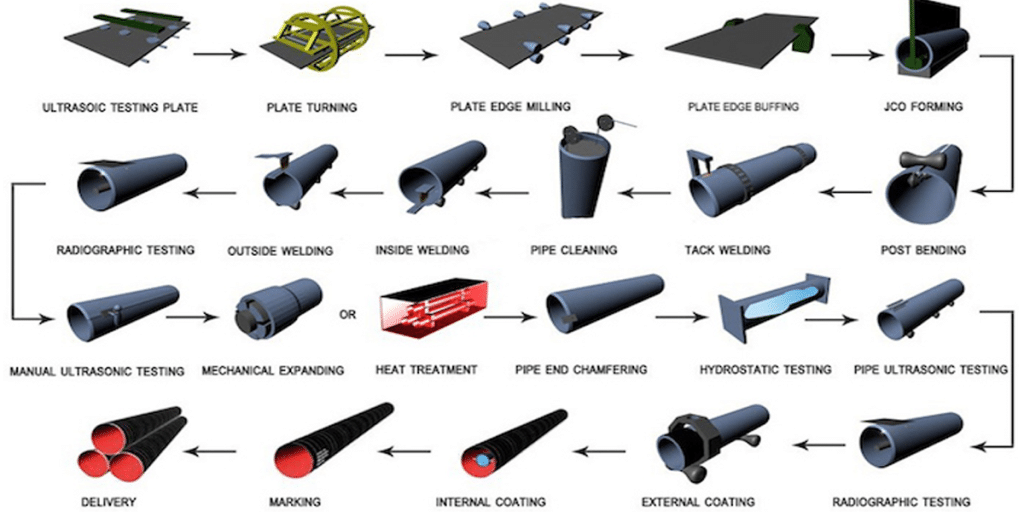

The Electric Fusion Welding (EFW) process is the core of ASTM A671 pipe manufacturing. LONGMA utilizes automatic welding systems with real-time monitoring to ensure consistent penetration and fusion.

Production Steps Overview:

| Step | Description | ASTM Reference |

| Edge Preparation | Milling edges for welding | ASTM A999 |

| Pipe Forming | Cold forming into cylindrical shape | ASTM A671 §6 |

| Welding | Automatic EFW process under controlled parameters | ASTM A671 §8 |

| Heat Treatment | Normalizing or stress-relieving | ASTM A671 §10 |

After welding, each pipe undergoes 100% radiographic or ultrasonic testing to ensure the weld seam is defect-free.

Internal Laboratory and Quality Testing

LONGMA’s in-house laboratory strictly follows ASTM and ASME standards for mechanical, chemical, and non-destructive testing. These tests include:

- Tensile Test— ASTM A370

- Impact Test (Charpy V-Notch)— ASTM E23

- Flattening & Bend Tests— ASTM A450

- Hydrostatic Test— ASTM A999

Such comprehensive testing ensures that every ASTM A671 CC65 Class 22 or ASTM A671 CC60 Class 22 pipe leaving the factory meets or exceeds international specifications.

Dimensional and Visual Inspection

Before delivery, pipes are checked for dimensional accuracy using calibrated instruments and gauging tools. Parameters like wall thickness, outer diameter, and roundness are verified per ASTM A671 specification to ensure perfect fit during installation.

Why LONGMA Is the Trusted Supplier for ASTM A671 EFW Pipes

LONGMA’s commitment to excellence goes beyond compliance. Our customers choose us because of:

- Certified production facilitieswith ISO and PED approvals

- Advanced EFW welding systemsensuring consistent quality

- Customizable solutionsfor different classes and materials

- Global project experiencein energy, oil, gas, and construction sectors

By integrating strict quality control with transparent test documentation, LONGMA reduces procurement risks and builds long-term trust with clients worldwide.

Conclusion

From raw material inspection to final packaging, every step in LONGMA’s manufacturing process reflects precision and reliability. The ASTM A671 EFW pipe—especially grades such as ASTM A671 CC60 Class 22 and ASTM A671 CC65 Class 22—is a symbol of engineering integrity, ensuring that pipelines perform safely even under the most demanding conditions.

When it comes to sourcing ASTM A671 pipes, choose LONGMA—your reliable partner in global infrastructure development.