- 1. Understanding ASTM A672 and Its Global Applications

- 2. Global Market Demand: Key Regions and Growth Drivers

- 3. Export Trends: China’s Leadership in ASTM A672 Production

- 4. Quality Assurance: Internal Laboratory and Testing System

- 5. Procurement Pain Points and LONGMA’s Solutions

- 6. Future Outlook: The Rising Demand for ASTM A672 Pipes

- 7. Why Choose LONGMA as Your ASTM A672 Export Partner

- 8. Conclusion: A Reliable Future for ASTM A672 Pipe Export

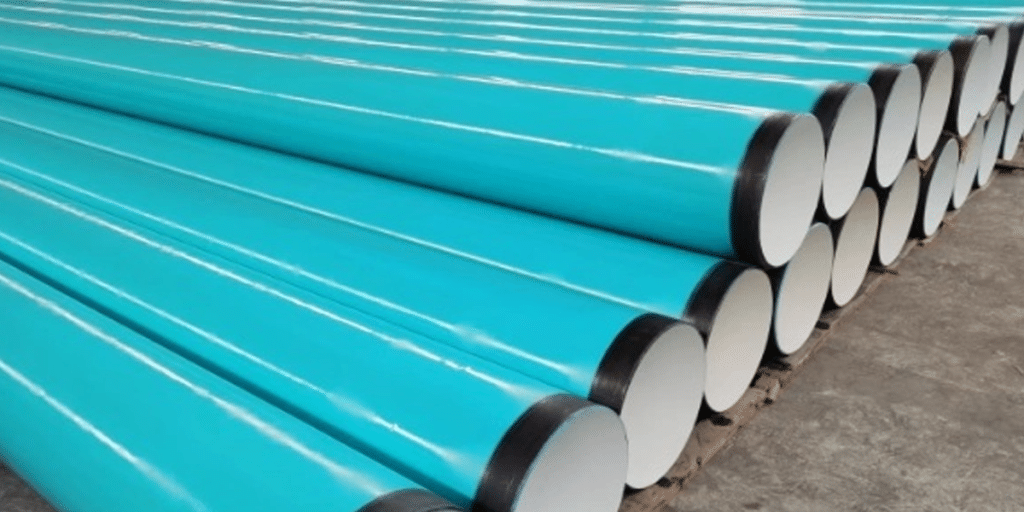

As global energy and industrial projects continue to expand, ASTM A672 steel pipes have become one of the most demanded welded pipe products in the international market.Known for their high strength, weld integrity, and adaptability under pressure, ASTM A672 pipes are widely used in oil and gas pipelines, power generation, and water transport systems.

With over 20 years of manufacturing experience, LONGMA has positioned itself as a reliable China ASTM A672 exporter, supplying high-performance ASTM A672 pipe products to customers in Asia, the Middle East, Europe, and South America.

Understanding ASTM A672 and Its Global Applications

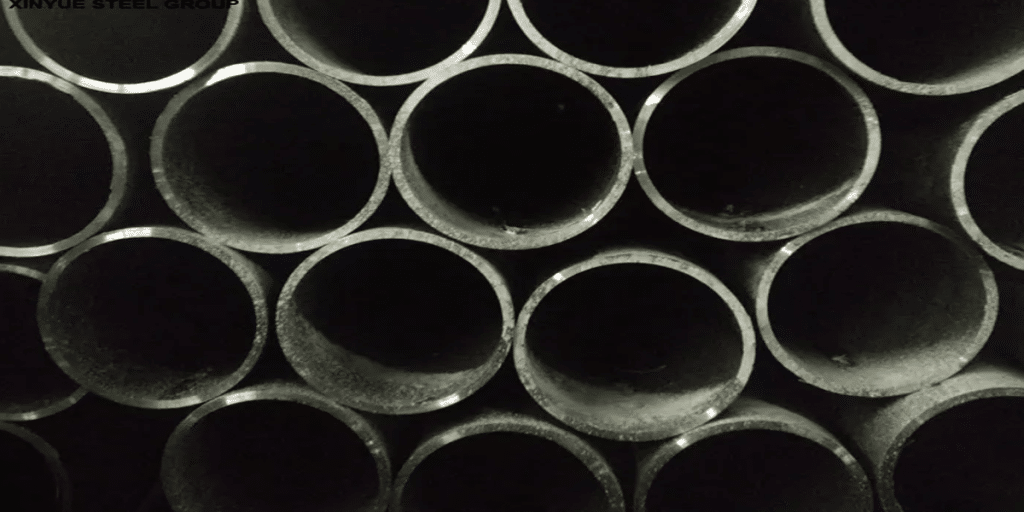

ASTM A672 is a specification for Electric Fusion Welded (EFW) steel pipes made from pressure vessel quality plates.

These pipes are typically used for high-temperature and high-pressure service applications such as steam lines, refinery piping, and thermal power plants.

Common Grades and Their Applications

| ASTM Grade | Heat Treatment Class | Yield Strength (MPa) | Primary Applications |

| ASTM A672 C60 CL22 | Normalized | 240 | Steam pipelines, medium-pressure systems |

| ASTM A672 C65 CL22 | Normalized + Stress Relieved | 260 | High-pressure water, oil, and gas pipelines |

| ASTM A672 C70 CL32 | Fully Annealed | 290 | Refinery, LNG, and power plant systems |

Each grade offers unique mechanical properties, making ASTM A672 C65 CL22 the most balanced choice for pressure and temperature stability in international projects.

Global Market Demand: Key Regions and Growth Drivers

The demand for ASTM A672 pipe continues to rise globally, especially in sectors focusing on energy infrastructure modernization and sustainable transportation systems.

Regional Market Overview

| Region | Market Demand Characteristics | Growth Rate (2024–2030) |

| Middle East | Strong demand from oil & gas pipelines, refinery expansions | 7.5% CAGR |

| Asia-Pacific | Rapid power plant and LNG terminal construction | 8.2% CAGR |

| Europe | Replacement of old carbon steel networks with ASTM A672 material | 5.3% CAGR |

| South America | Emerging demand from water transport and chemical industries | 6.0% CAGR |

LONGMA has established long-term partnerships in these regions, supplying ASTM A672 C65 and ASTM A672 C70 pipes that comply with both ASTM A672 specification and local quality standards such as EN 10204.

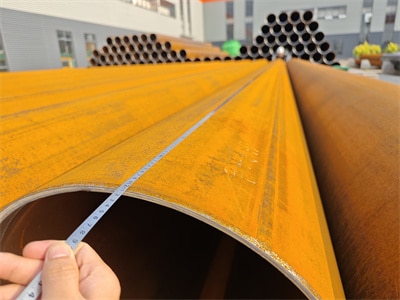

Export Trends: China’s Leadership in ASTM A672 Production

China remains one of the world’s largest exporters of ASTM A672 EFW pipes.

According to 2024 trade data, over 60% of global ASTM A672 exports originated from Chinese manufacturers, driven by improvements in automated welding technology, quality control, and third-party certification.

China’s Export Advantages (Compared with Global Suppliers)

| Parameter | China (LONGMA) | Europe/US Suppliers |

| Material Availability | Full grade range (C60–C70) | Limited |

| Production Cost | 15–25% lower | Higher labor cost |

| Delivery Time | 30–45 days | 60–90 days |

| Testing & Certification | In-house lab + SGS/BV | Third-party only |

With EFW factories certified under ISO 9001 and equipped with automatic ultrasonic and radiographic testing (UT/RT) systems, LONGMA ensures each ASTM A672 pipe meets or exceeds ASTM A672 specification standards.

Quality Assurance: Internal Laboratory and Testing System

To meet international procurement standards and minimize buyer risk, LONGMA has built an independent in-house laboratory that performs all major mechanical and non-destructive tests specified in ASTM A672 Sections 9–22.

| Test Type | ASTM Standard Reference | Purpose |

| Ultrasonic Test (UT) | ASTM E213 | Detects internal welding flaws |

| Radiographic Test (RT) | ASTM E94 | Ensures weld density and uniformity |

| Hydrostatic Test | ASTM A672 §22 | Verifies pressure resistance |

| Tensile & Yield Strength Test | ASTM A370 | Confirms mechanical performance |

This full-scale testing process not only guarantees product reliability but also enhances client trust, reducing inspection costs for overseas buyers.

Procurement Pain Points and LONGMA’s Solutions

Many overseas buyers face inconsistent material quality, incomplete documentation, and delayed delivery when sourcing ASTM A672 materials.

LONGMA addresses these challenges with a robust quality control and export support system.

| Buyer Concern | LONGMA’s Solution |

| Unverified chemical composition | Spectrographic chemical analysis per ASTM A672 chemical composition requirements |

| Incomplete inspection documents | Full EN 10204 3.2 & ASTM-compliant MTC provided |

| Quality variation between batches | Batch traceability with unique heat number system |

| Long lead times | Optimized EFW production lines for 24/7 operation |

With transparent documentation and strict adherence to ASTM A672 specification, LONGMA has become a trusted partner for EPC contractors and distributors worldwide.

Future Outlook: The Rising Demand for ASTM A672 Pipes

The next five years are expected to see sustained growth in the ASTM A672 pipe market, fueled by:

- The expansion of refinery and LNG infrastructure;

- Replacement of aging pipeline systems in Europe and North America;

- Increased adoption of ASTM A672 C65 CL22for high-pressure thermal applications;

- Global shift toward carbon steel materialsthat offer both cost efficiency and durability.

Industry forecasts estimate the global ASTM A672 market to reach USD 2.8 billion by 2030, with a compound annual growth rate (CAGR) of 6.8%.

Why Choose LONGMA as Your ASTM A672 Export Partner

As a leading China ASTM A672 exporter, LONGMA combines advanced production capabilities with international project experience:

- Over 20 years of EFW pipe manufacturing;

- Compliance with ASTM A672 C60, C65, and C70 grades;

- Automatic UT/RT, hydrostatic, and mechanical testingon every batch;

- Proven supply record in oil & gas, power generation, and chemical industries.

LONGMA doesn’t just sell pipes — it provides engineering confidence through consistent quality, reliable delivery, and full compliance documentation.

Conclusion: A Reliable Future for ASTM A672 Pipe Export

In a world demanding higher safety and performance standards, ASTM A672 steel pipes stand out as the ideal choice for high-pressure and high-temperature pipelines.

As the market continues to expand, LONGMA remains dedicated to offering globally competitive products backed by technical expertise, internal testing capabilities, and customer-centric service.

Whether you are sourcing ASTM A672 C65 CL22 for refinery projects or ASTM A672 C60 for industrial piping, LONGMA is your trusted long-term partner for success.