- 1. Understanding ASTM A672 and Its Material Grades

- 2. Pressure and Temperature: The Core Criteria for Grade Selection

- 3. Testing and Quality Assurance: Ensuring Reliability

- 4. Addressing Procurement and Quality Risks

- 5. Example: Material Selection in Real Projects

- 6. Why Choose LONGMA for ASTM A672 Pipe Supply

- 7. Conclusion: Choose the Right Grade, Secure the Right Results

In industrial pipeline design—especially for high-pressure steam, water, and oil transport systems—selecting the correct material grade is crucial for safety, efficiency, and cost-effectiveness. The ASTM A672 specification provides a comprehensive standard for Electric Fusion Welded (EFW) steel pipes used in moderate to high-temperature service applications.

With over 20 years of experience in steel pipe manufacturing, LONGMA has helped global clients determine the most suitable ASTM A672 pipe grades for their operating environments. This article explores how to select the right grade based on pressure, temperature, and service conditions, ensuring both performance reliability and project longevity.

Understanding ASTM A672 and Its Material Grades

The ASTM A672 standard covers EFW pipes made from pressure vessel-quality carbon steel plates, designed for service at moderate to high temperatures. It defines multiple grades (C60, C65, C70) and classes (CL12, CL22, CL32) based on heat treatment and testing requirements.

| Grade | Heat Treatment Class | Minimum Yield Strength (MPa) | Typical Service Temperature | Common Applications |

| ASTM A672 C60 CL22 | Normalized | 240 | Up to 400°C | Steam lines, medium-pressure water systems |

| ASTM A672 C65 CL22 | Normalized + Stress Relieved | 260 | Up to 450°C | High-pressure steam and oil lines |

| ASTM A672 C70 CL32 | Fully Annealed | 290 | Up to 500°C | Refinery and power generation piping |

Each grade offers a different balance of strength, ductility, and thermal stability, making selection dependent on project-specific stress and temperature parameters.

Pressure and Temperature: The Core Criteria for Grade Selection

Selecting the correct ASTM A672 pipe grade begins with analyzing operating pressure and temperature requirements.

| Operating Pressure (MPa) | Recommended Grade | Remarks |

| ≤6.5 MPa (Low Pressure) | ASTM A672 C60 CL22 | Economical choice for general steam lines |

| 6.5–10 MPa (Medium Pressure) | ASTM A672 C65 CL22 | Enhanced stress resistance and weld toughness |

| ≥10 MPa (High Pressure / High Temperature) | ASTM A672 C70 CL32 | Ideal for refinery boilers and LNG vaporization systems |

- High-Pressure Environments: Choose higher grades like ASTM A672 C65 CL22or C70, which provide higher yield and tensile strength to withstand internal stress.

- Elevated Temperature Operations: For pipelines exposed to temperatures above 450°C, ASTM A672 C70 CL32is recommended due to its superior heat treatment and structural stability.

- Cyclic Pressure Conditions: ASTM A672 C65 CL22is preferred for fluctuating load and temperature systems (e.g., power plants and petrochemical units).

Testing and Quality Assurance: Ensuring Reliability

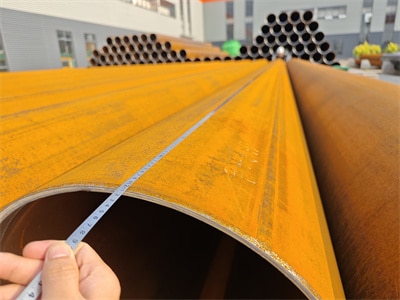

Every ASTM A672 pipe undergoes rigorous inspection as defined in ASTM A672 §9–§22, including both non-destructive and mechanical tests. LONGMA’s internal laboratory strictly implements these procedures to guarantee consistency and reliability.

| Test Type | Standard Reference | Purpose | Testing Stage |

| Ultrasonic Testing (UT) | ASTM E213 | Detect internal defects in welds | Post-weld |

| Radiographic Testing (RT) | ASTM E94 | Verify weld soundness | Sampling |

| Hydrostatic Testing | ASTM A672 §22 | Confirm pressure-tightness | Final inspection |

| Tensile and Yield Testing | ASTM A370 | Validate mechanical properties | Material approval stage |

By integrating automated EFW welding and post-weld heat treatment, LONGMA ensures each ASTM A672 pipe meets or exceeds required pressure vessel standards.

Addressing Procurement and Quality Risks

Many project managers face uncertainty when sourcing ASTM A672 material internationally—particularly regarding standard compliance, testing reliability, and delivery guarantees.

LONGMA directly addresses these pain points with its transparent quality control system and third-party verification (BV, SGS, TUV).

| Client Concern | LONGMA’s Assurance |

| Inconsistent material composition | 100% spectrometer-tested chemical composition per ASTM A672 |

| Hidden welding defects | Full UT/RT reports with traceable batch numbers |

| Delayed delivery | Complete in-house production from plate to finished pipe |

| Documentation | MTC (EN 10204 3.2) and ASTM-compliant test certificates provided |

Example: Material Selection in Real Projects

In a recent LNG pipeline project in Southeast Asia, the design pressure exceeded 9.5 MPa, with operating temperatures around 420°C. After comprehensive stress analysis, LONGMA recommended ASTM A672 C65 CL22 pipes.

Results:

- 15% longer service life compared to C60 pipes;

- Excellent weld integrity verified through 100% radiographic inspection;

- Reduced maintenance costs and improved operational safety.

This case demonstrates how the correct grade selection—supported by standard-based testing—directly impacts performance and project ROI.

Why Choose LONGMA for ASTM A672 Pipe Supply

LONGMA is not just a China ASTM A672 exporter, but a reliable engineering partner offering end-to-end solutions:

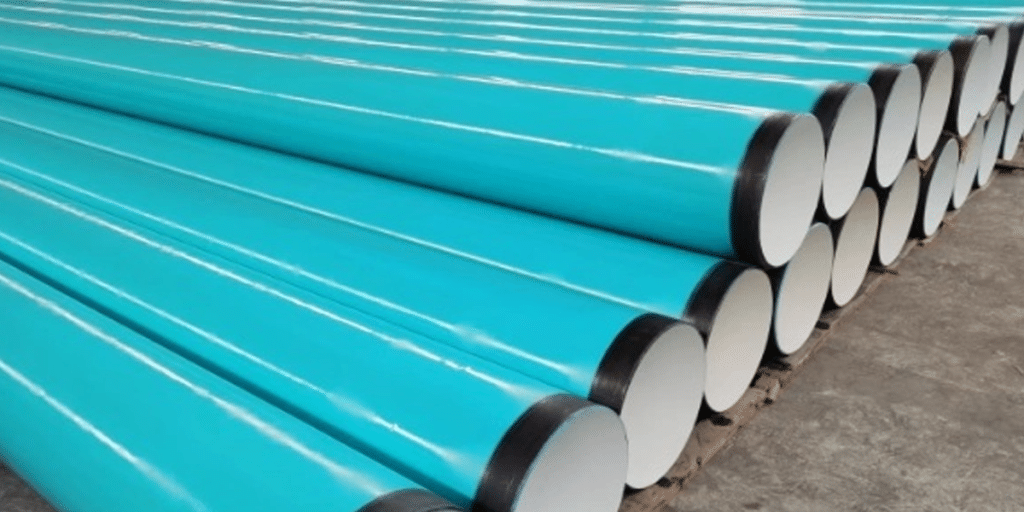

- Over 20 years of EFW pipe manufacturing experience;

- Full compliance with ASTM A672 specification;

- Advanced non-destructive testing (NDT)and hydrostatic testing facilities;

- Customizable dimensions, coatings, and heat treatments.

For clients seeking long-term reliability and certified quality, LONGMA ensures each ASTM A672 pipe delivers unmatched strength, precision, and consistency.

Conclusion: Choose the Right Grade, Secure the Right Results

The right ASTM A672 grade selection determines the safety, durability, and efficiency of your piping system. By understanding the balance between pressure, temperature, and grade properties, project engineers can make informed, risk-free decisions.

Partnering with LONGMA means gaining access to expert engineering advice, in-house testing, and proven material performance — ensuring your ASTM A672 c65 cl22 pipes perform flawlessly in even the most demanding conditions.