In the wave of continuous global industrial upgrades, steel pipe standards and selection have become a focal point for many companies. Whether in oil and gas pipeline projects or high-temperature, high-pressure boiler applications, how to choose the right steel pipe standard directly affects project safety, costs, and the convenience of later maintenance. Faced with a wide variety of specifications on the market—such as ASTM A53, ASTM A106, and API 5L—many engineering professionals are seeking a practical steel pipe selection guide to help them understand the performance differences and application areas of each standard.

In recent years, with the rapid development of the energy, chemical, and infrastructure sectors, the application of ASTM A106 steel pipes has been growing year by year, while the basis for selecting API 5L pipes is also receiving increasing attention. At the same time, making a scientifically sound choice among numerous standards and complex specifications has become a crucial issue at the initial stage of every engineering project. This article will focus on the core question of how to choose steel pipe standards, and will offer you a comprehensive and practical reference—from standard comparisons and application scenarios to steel pipe standard selection techniques—to help every engineer accurately realize the value of each steel pipe.

Overview of Common Steel Pipe Standards

Steel pipes are widely used across the globe in fields such as oil and gas transportation, chemical equipment, high-temperature and high-pressure piping, and structural engineering. Due to the diverse operating environments and conditions, how to choose the right steel pipe standard becomes a critical decision at the start of every engineering project. This article provides a systematic review and comparison of several widely used standards in the industry, helping you build a practical steel pipe selection guide.

1. ASTM A53

ASTM A53 is a carbon steel pipe standard developed by the American Society for Testing and Materials (ASTM), mainly intended for mechanical and pressure applications as well as general-purpose piping.

Standard Features:

Types: Seamless and welded (black and galvanized)

Wide nominal size range

Suitable for medium to low pressure

Material: Carbon steel

Typical Applications:

Fire protection piping

HVAC and ventilation systems

General fluid transportation

Selection Tip:

If your project does not require stringent temperature or pressure conditions, ASTM A53 is an economical and readily available general-purpose standard.

2. ASTM A106

ASTM A106 is designed specifically for high-temperature service and is one of the most common seamless carbon steel pipe standards in the US.

Standard Features:

Type: Seamless only

Grades: A, B (most common), and C

Suitable for high-temperature and high-pressure service

ASTM A106 Steel Pipe Applications:

Power plant boilers

High-temperature petrochemical plants

Refineries and pressure vessels

Selection Tip:

For applications involving high-temperature fluid transport, ASTM A106 is often recommended in steel pipe selection guides for its excellent heat resistance and reliability.

3. API 5L

API 5L is a standard developed by the American Petroleum Institute (API), primarily for oil and gas pipeline transportation.

Standard Features:

Types: Seamless and welded

Technical grades: PSL1 and PSL2 (PSL2 is more stringent)

Strength grades range from B to X80

API 5L Steel Pipe Selection Basis:

Long-distance oil and gas transmission

High strength and corrosion resistance requirements

Buried pipelines

Selection Tip:

Type: Seamless

Materials: Alloy steel or carbon steel

Temperature capability: Can withstand temperatures above 580℃

Common grades: St35.8, 15Mo3, etc.

For cross-regional long-distance pipelines, API 5L offers a wide range of grades and excellent reliability, making it a preferred choice.

4. DIN 17175

DIN 17175 is a German standard specifically for high-temperature seamless steel pipes, especially suited for high-temperature and high-pressure environments such as boilers and heat exchangers.

Standard Features:

Typical Applications:

Power station boilers

High-temperature heat exchanger tubing

Industrial furnace piping

Selection Tip:

For European projects or those involving high-temperature equipment, DIN 17175 is widely used for its superior high-temperature performance and strict quality standards.

How to Select the Right Steel Pipe Standard Based on Project Requirements?

In engineering projects, choosing the appropriate steel pipe standard directly affects safety, compliance, and overall project cost.

1️⃣ Define Basic Project Requirements

Before selecting any standard, you must accurately define your project needs:

✅ Medium Type

Fluids: water, oil, gases (natural gas, steam)

Corrosive chemicals: acidic or alkaline solutions, seawater

Structural use: supports and load-bearing frameworks

For example, if you need to transport high-temperature steam, the application of ASTM A106 steel pipes is one of the most typical scenarios, widely used in power station boilers and high-temperature process lines.

✅ Operating Environment

Temperature: high (>400°C) or low (<-20°C)

Pressure level: high-pressure (e.g., transmission pipelines) or low-pressure systems

Corrosive environment: marine platforms, buried pipelines in acidic soils

Mechanical loads: vibration, impact, fatigue

✅ Regulations and Certifications

Industry standards: Oil & Gas (API), Chemicals (ASTM, ASME), Construction (EN, ISO)

Regional standards: Europe/US (ASTM, EN), China (GB/T)

🌟 Steel pipe standard selection tips: Always confirm mandatory regulatory standards first—meeting performance alone is not sufficient for approval.

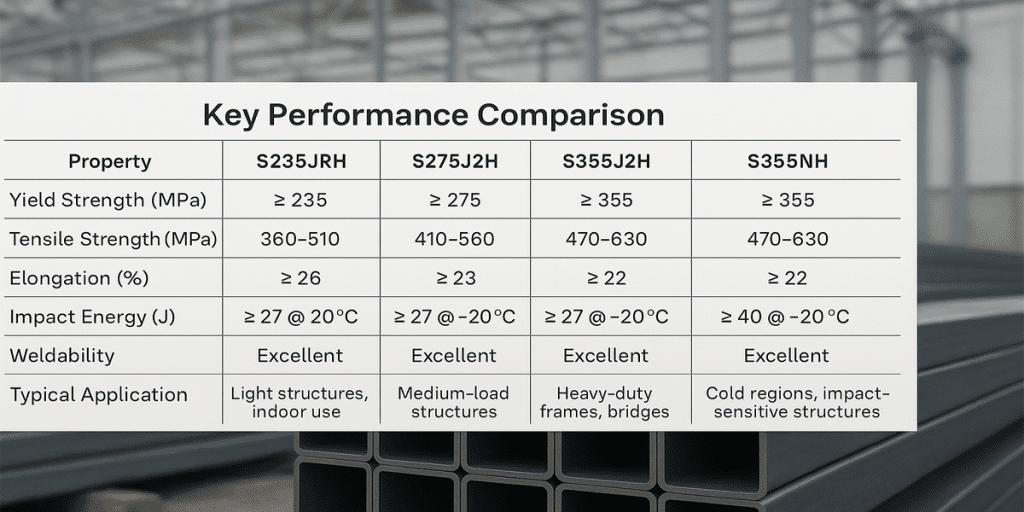

2️⃣ Key Performance Indicators

Within the steel pipe selection guide, performance matching is at the core of decision-making:

✅ Mechanical Properties

Strength: High-pressure transmission requires high yield strength

For example, API 5L pipe selection basis: Grades like X52, X70, X80 are used in long-distance gas pipelines for high strength and excellent weldability.

Toughness: Low-temperature impact resistance

ASTM A333 Grade 6 is designed for -45°C service conditions.

✅ Corrosion Resistance

Acidic or salt spray environments: use stainless steel or special corrosion protection

ASTM A312 316L is suitable for chemical media

ASTM A53 can be galvanized for buried or outdoor pipelines

✅ Dimensions and Tolerances

Precision tubes (hydraulic or mechanical) require tight dimensional tolerances

EN 10305-1 is ideal for precision applications

🌟 Steel pipe standard selection tips: Always evaluate strength, toughness, and corrosion resistance together—never isolate one factor.

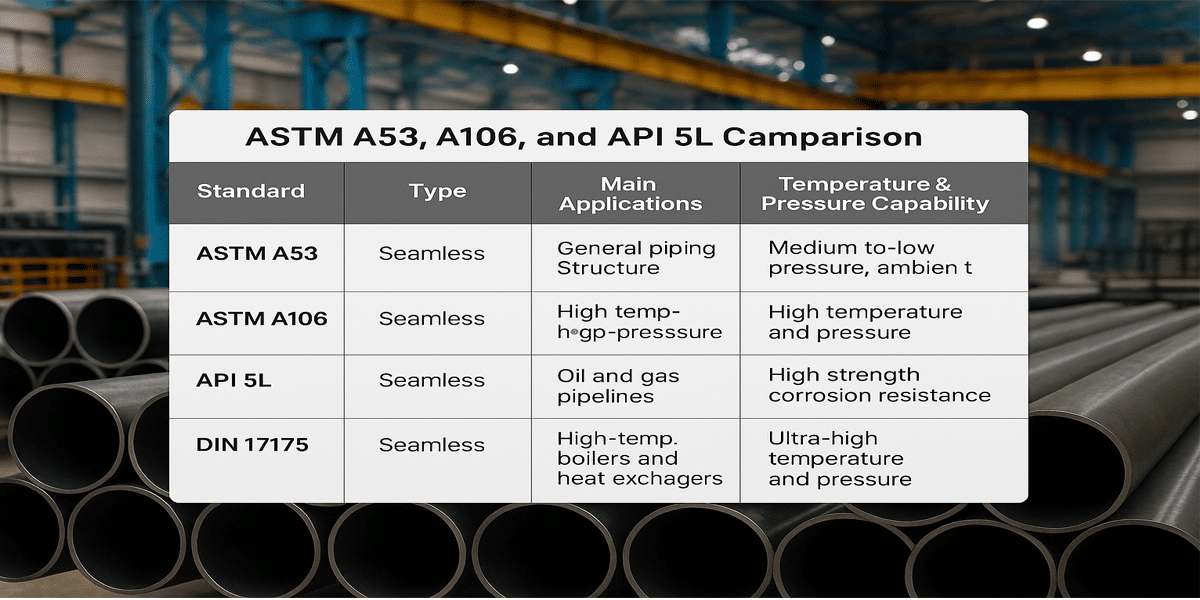

3️⃣ Common Standards and Applications

In practice, different standards are selected for different working conditions. The table below offers a comparison of ASTM A53, A106, and API 5L, among other common standards:

🌟 The application of ASTM A106 steel pipes is very common in power plant high-temperature piping, while API 5L is the internationally recognized preferred standard in oil and gas transmission.

4️⃣ Process and Cost Balance

Beyond technical standards, you must consider manufacturing methods and cost efficiency:

✅ Seamless Pipes (ASTM A106)

Advantages: excellent integrity, superior pressure and temperature resistance

Disadvantages: longer production time, higher cost

Recommended for high-temperature, high-pressure services.

✅ Welded Pipes (ASTM A53)

Advantages: cost-effective, fast production

Disadvantages: weld quality has a significant impact on performance

Suitable for medium- and low-pressure applications.

✅ Surface Treatments and Coatings

Galvanizing: ASTM A53 galvanized pipes are ideal for outdoor or buried installation

Fusion Bonded Epoxy (FBE) coating: commonly applied to API 5L buried pipelines

🌟 Steel pipe selection guide tip: If your project demands both high-pressure/high-temperature and corrosion resistance, consider ASTM A106 seamless alloy pipes or DIN 17175 materials.

Detailed Basis for Selecting Steel Pipe Standards

In any engineering project, how to choose a steel pipe standard is a critical decision that directly affects safety, compliance, and project economics.

1️⃣ Project Working Conditions

This is the most fundamental starting point in any steel pipe selection guide, and includes:

✅ Type of Medium

Fluid media: water, oil, natural gas, steam

For example: when transporting natural gas, API 5L X70 offers high yield strength and good toughness. The API 5L pipe selection basis focuses on strength, weldability, and corrosion resistance.

Corrosive media: chemicals, acidic or alkaline solutions

In this case, ASTM A312 stainless steel standards are often preferred.

Structural applications: load-bearing supports

✅ Temperature and Pressure

High temperature (>400°C): choose ASTM A106 seamless pipes or DIN 17175 high-temperature pipes

Low temperature (<-20°C): consider ASTM A333 low-temperature pipes

High pressure: API 5L or higher grades of ASTM A106 are recommended

✅ Installation and Service Environment

Marine environments: require additional anti-corrosion protection (e.g., 3PE, FBE coating)

Underground installations: need soil corrosion resistance

Outdoor exposure: ASTM A53 galvanized pipes can be used

2️⃣ Regulatory and Certification Requirements

In steel pipe standard selection tips, compliance is absolutely essential:

✅ International Standards

API: oil and gas sector, such as API 5L, API 5CT

ASTM: widely applied in US and international engineering

EN/DIN: required for EU projects

✅ National/Regional Standards

Chinese GB/T standards

European EN series standards

✅ Client or Industry Specifications

Oil & Gas, chemical, and power industries often require specific documentation and certificates

🌟 Tip:

When doing an ASTM A53 A106 API 5L comparison, don’t only look at performance—always confirm if the standard is legally recognized in the project region.

3️⃣ Performance and Manufacturing Requirements

In the steel pipe selection guide, performance matching is the core consideration:

✅ Mechanical Properties

Yield strength, tensile strength: define pressure containment capability

Impact toughness: critical for low-temperature or vibration-prone applications

Ductility and weldability: affect manufacturing and installation

✅ Corrosion Resistance

Highly corrosive environments: prioritize stainless or alloy steels

For example, the application of ASTM A312 316L pipes is mainly in chemical and marine projects.

Moderate corrosion: ASTM A53 galvanized pipes are commonly used

✅ Dimensions and Tolerances

Precision machining or hydraulic systems: EN 10305 series pipes

General transport pipelines: API and ASTM standards with standard tolerances

4️⃣ Process and Cost Balance

Different standards involve different manufacturing methods, and costs can vary significantly:

✅ Seamless Steel Pipes

Advantages: high reliability, excellent high-pressure and high-temperature performance

Typical standards: ASTM A106, DIN 17175

Applications: power plants, high-temperature service

✅ Welded Steel Pipes

Advantages: lower cost, higher production efficiency

Typical standard: ASTM A53

Applications: low-pressure fluid transport, structural purposes

✅ Special Surface Treatments

Anti-corrosion coatings: 3PE, FBE

Hot-dip galvanizing: improves weather resistance

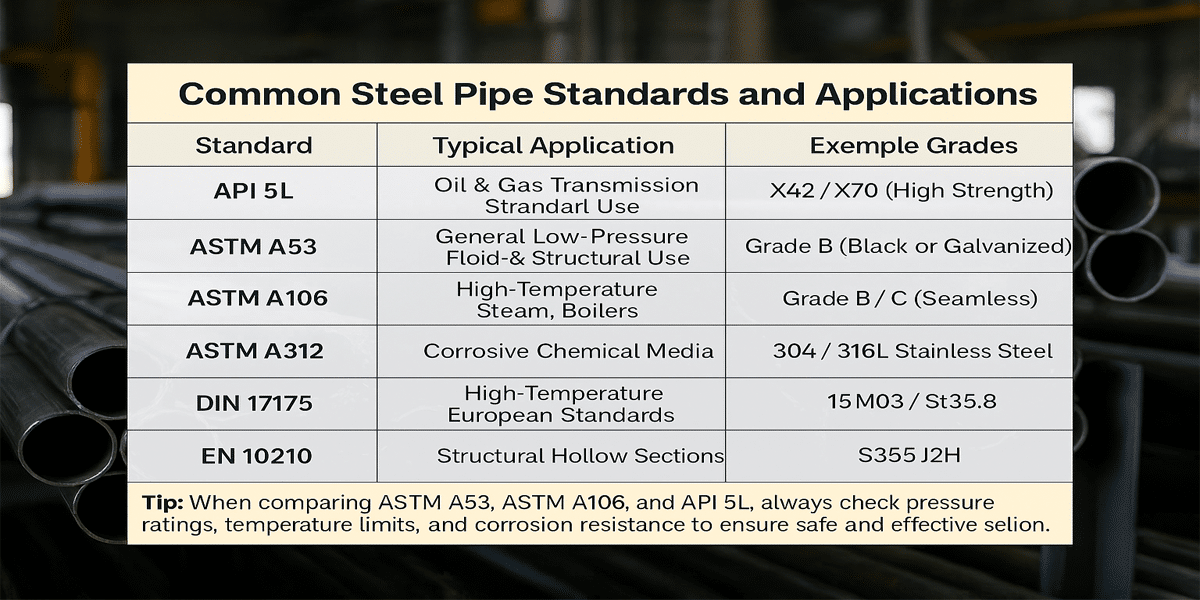

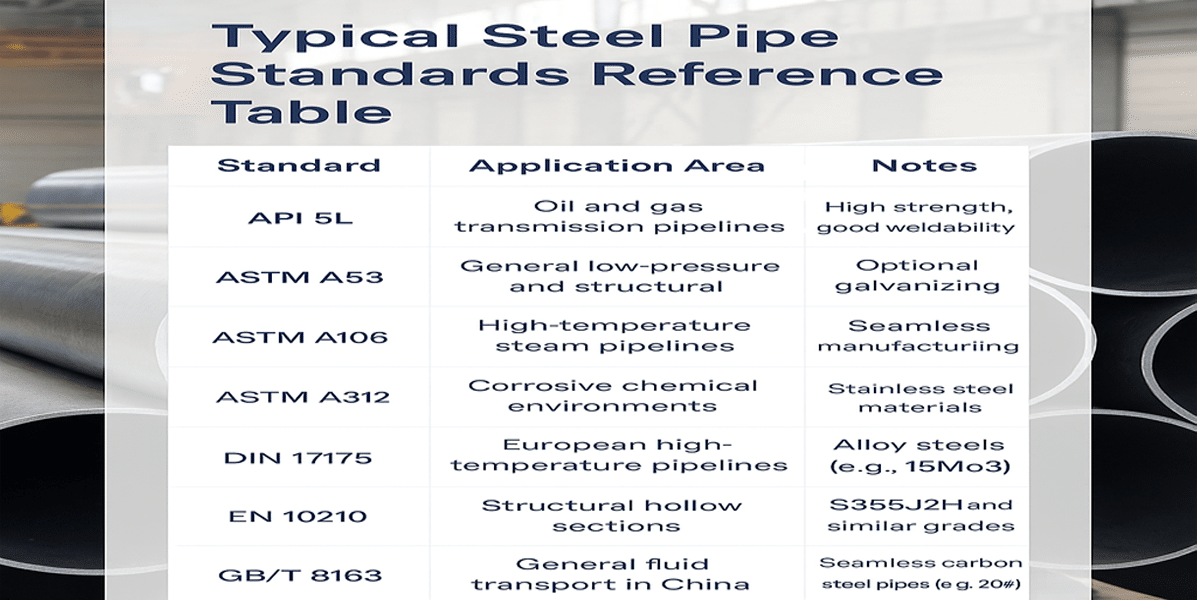

5️⃣ Typical Standards Reference Table

Here is a concise comparison table for initial selection:

Application Scenario Analysis of Common Steel Pipe Standards

Understanding the typical scenarios each standard applies to is the most critical part of how to choose a steel pipe standard. Here is a detailed analysis:

1️⃣ API 5L — Oil and Gas Transmission Pipelines

✅ Application Areas:

Long-distance oil and gas pipelines

Urban gas distribution networks

Offshore subsea pipelines

✅ Key Features:

Multiple steel grades (X42, X52, X65, X70, X80)

High yield strength and excellent weldability

PSL1 and PSL2 product specifications (PSL2 has stricter quality requirements)

✅ Typical Examples:

West–East Gas Pipeline Project

Offshore gas platform pipelines

👉 API 5L pipe selection basis:

Transmission pressure

Corrosion resistance in buried or marine environments

Structural safety in long-distance transport

2️⃣ ASTM A53 — General Low-Pressure and Structural Use

✅ Application Areas:

Fire protection pipelines

Water supply and drainage

General structural supports

✅ Key Features:

Available in seamless and welded types

Optional hot-dip galvanizing for corrosion resistance

Excellent cost performance for non-high-pressure use

✅ Typical Examples:

Fire sprinkler systems in commercial buildings

Municipal water distribution networks

👉 In the ASTM A53 A106 API 5L comparison, ASTM A53 is more oriented toward low-pressure and construction applications, while API 5L targets high-pressure transmission.

3️⃣ ASTM A106 — Seamless High-Temperature and High-Pressure Pipe

✅ Application Areas:

Power plant boiler pipelines

High-temperature steam transportation

Petrochemical process piping

✅ Key Features:

Suitable for service temperatures from -29°C to +538°C

Seamless manufacturing ensures high reliability

Common grades: Grade B and Grade C

✅ Typical Examples:

Main high-temperature steam pipelines in thermal power stations

Refinery process piping

👉 ASTM A106 pipe applications focus on high-temperature and high-pressure service.

4️⃣ DIN 17175 — High-Temperature Alloy Steel Pipe

✅ Application Areas:

Boiler pipelines in European markets

High-temperature chemical process equipment

Heat exchangers

✅ Key Features:

Suitable for high-temperature loads

Typical materials: 15Mo3, 13CrMo44

Good creep resistance

✅ Typical Examples:

Main steam pipelines in European thermal power plants

5️⃣ ASTM A312 — Stainless Steel Corrosion-Resistant Pipe

✅ Application Areas:

Chemical industry and food-grade fluid transport

Marine engineering pipelines

Pharmaceutical equipment piping

✅ Key Features:

Available in multiple materials (304, 316L, 321)

Superior corrosion resistance

Excellent weldability and polishability

✅ Typical Examples:

Saltwater delivery systems

Sanitary piping in food processing plants

Through an in-depth analysis of common steel pipe standards and their application scenarios, it is clear that proper selection is not only about compliance but also directly impacts the safety, durability, and cost-effectiveness of your project. Whether you are dealing with high-temperature, high-pressure conditions or environments requiring exceptional corrosion resistance, you must comprehensively compare the technical specifications and suitability of different standards. We hope this steel pipe selection guide provides you with practical insights to support informed decision-making in your project planning. If you have further questions about how to choose steel pipe standards, ASTM A53 A106 API 5L comparison, or other steel pipe standard selection tips, please feel free to contact us. Together, we will find the solution that best fits your project needs!