- 1. Basic Material Characteristics and Applicable Standards of S235JR

- 2. Overview of S235JR Mechanical Properties (Yield, Tensile, Elongation)

- 3. In-Depth Interpretation of the S235JR Stress–Strain Curve

- 4. Performance Comparison with Common Structural Steels (S275, S355, Q235)

- 5. Testing Methods to Ensure the True Mechanical Properties of S235JR

- 6. Why LONGMA S235JR Is More Reliable?

- 7. Application Recommendations: When Is S235JR the Right Choice?

- 8. Conclusion: Choosing the Right Supplier Is More Important Than Choosing the Steel Grade

In structural steel procurement, S235JR is one of the most widely used non-alloy structural steels due to its stable performance and excellent processability. It is commonly applied in steel structures, mechanical components, infrastructure, and pipe systems. However, different projects have different requirements for strength, ductility, and safety factors. Therefore, customers’ most frequent questions usually include:

- What is the S235JR tensile strength?

- Does the S235JR yield strength meet the project requirements?

- Do the S235JR mechanical properties vary with thickness?

- How does the S235JR stress strain curve reflect its actual strength performance?

This article provides a professional and comprehensive analysis of these performance indicators and explains how LONGMA’s in-house laboratory ensures stable product quality, helping you reduce procurement risks and make more accurate material selections.

Basic Material Characteristics and Applicable Standards of S235JR

S235JR belongs to the EN 10025-2 standard for structural steel. The “JR” designation represents compliance with Charpy impact energy ≥ 27J at +20°C.

Overview of S235JR Mechanical Properties (Yield, Tensile, Elongation)

The table below lists the typical mechanical property requirements of S235JR according to EN 10025-2:

Standard Mechanical Properties of S235JR (Thickness-Dependent)

| Thickness t (mm) | s235jr yield strength (MPa) | s235jr tensile strength (MPa) | Elongation A (%) |

| ≤ 16 | ≥ 235 | 360–510 | 26 |

| 16–40 | ≥ 225 | 360–510 | 25 |

| 40–63 | ≥ 215 | 360–510 | 23 |

| 63–100 | ≥ 205 | 360–510 | 22 |

These values are the core criteria used by engineers when selecting S235JR and are critical for evaluating load-bearing capability, weldability, and structural safety.

In-Depth Interpretation of the S235JR Stress–Strain Curve

To help users better understand strength performance, the following table provides an analytical breakdown of a typical S235JR stress strain curve:

Key Stages of the S235JR Stress–Strain Curve

| Stage | Stress Change | Material Behavior | Engineering Meaning |

| Elastic Region | Linear increase | No permanent deformation | Defines Elastic Modulus (E) used for calculations |

| Yield Plateau | Stress remains constant | Material enters yielding | Defines s235jr yield strength |

| Strain Hardening | Stress increases again | Material hardens | Reflects reserve strength |

| Ultimate Tensile Point | Maximum stress | Equivalent to s235jr tensile strength | Determines maximum load |

| Necking & Fracture | Stress drops | Localized thinning and fracture | Indicates ductility & toughness |

Thus, the s235jr stress strain curve reveals not only the strength index but also ductility, toughness, and safety margins.

Performance Comparison with Common Structural Steels (S275, S355, Q235)

To support rapid selection decisions, the following comparison table is provided:

Comparison of Yield and Tensile Strength Between S235JR and Other Grades

| Grade | Yield Strength (MPa) | Tensile Strength (MPa) | Typical Application |

| S235JR | 235 | 360–510 | General structures, weldments, steel pipes |

| S275JR | 275 | 370–530 | Medium-strength structures, bridges |

| S355JR | 355 | 470–630 | High-strength structures, machinery |

| Q235B | 235 | 370–500 | Common Chinese structural steel |

Although this article does not focus on comparisons, the data clearly shows:

S235JR offers excellent overall balance between strength, weldability, and cost.

Testing Methods to Ensure the True Mechanical Properties of S235JR

LONGMA’s in-house laboratory follows international standards to verify the mechanical properties of S235JR, including:

- Tensile Test (ASTM E8 / ISO 6892)

Used to determine s235jr tensile strength, s235jr yield strength, and ductility indicators.

Equipment: Electronic universal testing machine

Output: Stress–strain curve (s235jr stress strain)

- Charpy Impact Test (JR Requirement)

Standard: ISO 148-1

Purpose: Ensure ≥ 27J at +20°C

- Metallographic Examination

Checks grain size, segregation, and uniformity to guarantee stable weldability.

- Chemical Composition Analysis (ASTM E415)

Ensures proper C, Mn, Si content aligned with EN 10025.

These tests ensure every batch of S235JR meets s235jr mechanical properties requirements.

Why LONGMA S235JR Is More Reliable?

- Stable Steel Source System

- Partnership with major mills (Baosteel, Yonggang, Shandong Steel, etc.)

- Each batch includes mill MTC + LONGMA secondary test report

- Full In-House Laboratory Capability

Ensures compliance with:

- s235jr tensile strength

- s235jr yield strength (235 MPa minimum)

- Impact & chemistry consistency

- 20+ Years of Export Experience

- Understanding of EU, Middle East, Southeast Asia inspection requirements

- EN 10204 3.1 / 3.2 certificates available

- Custom Processing Capability

- Cutting, beveling, forming, CNC fabrication

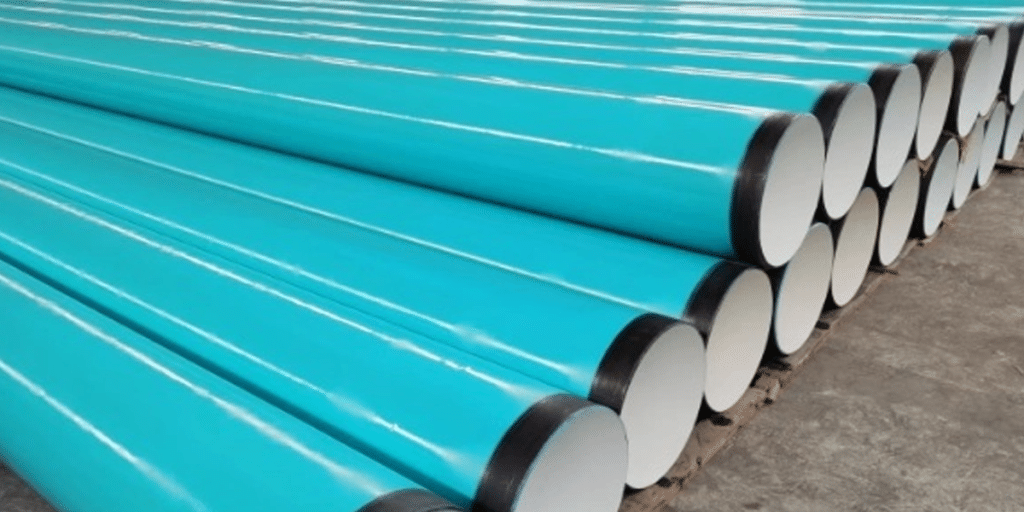

- Full range supply (plate, pipe, angle, round bar)

Application Recommendations: When Is S235JR the Right Choice?

Suitable Application Scenarios:

| Scenario | Why S235JR Works Well |

| Building structures | Good strength + weldability |

| Mechanical components | Reliable tensile/yield performance |

| Pipe structures | High cost performance |

| Infrastructure | Stable and predictable performance |

For higher strength requirements, S275JR or S355JR is recommended.

For enhanced weldability, you may choose S235JR +N (normalized state).

Conclusion: Choosing the Right Supplier Is More Important Than Choosing the Steel Grade

From s235jr tensile strength and s235jr yield strength to the full set of s235jr mechanical properties, these indicators reflect not only safety performance but also your supplier’s professionalism.

With LONGMA’s in-house laboratory, strict quality control system, and 20+ years of export experience, we provide:

✔ Stable-performance S235JR

✔ Professional technical support

✔ Complete inspection reports

✔ Full traceability

If you are looking for a reliable, long-term structural steel supplier, LONGMA is ready to support your project with a safer and more efficient material solution.