In modern industrial applications, ASTM A671 EFW pipes are widely recognized for their excellent mechanical strength, corrosion resistance, and high-quality welding performance. They are the preferred material in energy, chemical, and power generation industries.

With over 20 years of experience, LONGMA has become a trusted global manufacturer by leveraging advanced technology, strict quality control, and a deep understanding of the ASTM A671 material standard.

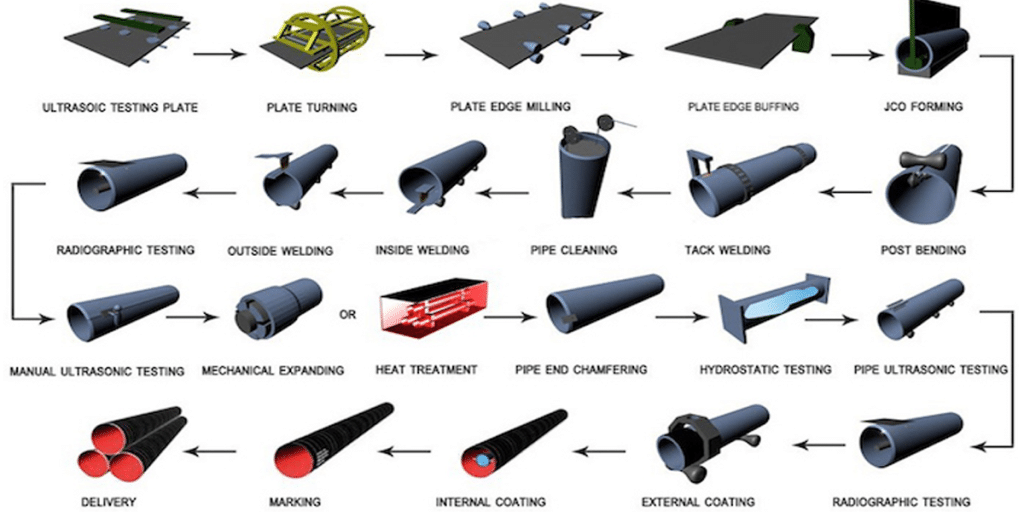

This article takes you inside LONGMA’s production process — exploring how advanced manufacturing and testing techniques ensure the reliability and performance of every ASTM A671 steel pipe.

Overview of the ASTM A671 Pipe Manufacturing Process

ASTM A671 EFW pipe is produced through Electric Fusion Welding (EFW) — a method designed for low to medium temperature and pressure piping systems. The production process involves multiple critical stages, each performed with precision to meet international standards.

| Production Stage | Description | Objective |

| Raw Material Preparation | Select high-grade steel plates that comply with ASTM A671 material specifications from certified suppliers. | Ensure the chemical composition and physical properties meet ASTM standards. |

| Plate Forming & Welding | Roll the steel plates into cylindrical shapes and weld them using the EFW process. | Achieve high-quality weld seams with strong pressure and corrosion resistance. |

| Heat Treatment (PWHT) | Apply post-weld heat treatment to relieve residual stress and improve toughness. | Enhance ductility, crack resistance, and overall longevity. |

| Finishing & Coating | Adjust dimensions, apply anti-corrosion coatings, and conduct final polishing. | Ensure durability, dimensional precision, and corrosion protection. |

EFW Welding Technology Explained

Welding is the heart of ASTM A671 EFW pipe manufacturing. The Electric Fusion Welding (EFW) process offers deep penetration, consistent results, and excellent control — making it ideal for thick-wall pipe production.

| Welding Advantage | Explanation |

| Deep Fusion and Strong Welds | EFW achieves full penetration, minimizing porosity and inclusions. |

| Suitable for Thick-Walled Pipes | Perfect for heavy-duty grades like ASTM A671 CC60, CC65, and CC70. |

| High Consistency | Automated control of welding current and speed ensures stable weld quality. |

| Improved Ductility Post-Heat Treatment | PWHT eliminates residual stresses and improves crack resistance. |

Testing Procedures and Quality Control

Each ASTM A671 steel pipe undergoes rigorous inspection to guarantee compliance with international standards. LONGMA employs advanced testing equipment and strict quality assurance procedures throughout production.

| Test Type | Description | Purpose |

| Chemical Composition Analysis | Optical emission spectrometers analyze alloy elements (C, Mn, S, P). | Ensure compliance with ASTM A671 material standards. |

| Mechanical Property Tests | Tensile, impact, and bend tests. | Verify the strength and toughness of ASTM A671 CC60 class 22 and other grades. |

| Nondestructive Testing (NDT) | Ultrasonic and radiographic tests detect internal or surface flaws. | Guarantee weld integrity and prevent leakage risks. |

| Hydrostatic Pressure Test | Each pipe is pressurized above design limits. | Confirm sealing and pressure resistance. |

| Visual & Dimensional Inspection | Check surface quality and pipe diameter tolerances. | Ensure flawless appearance and dimensional accuracy. |

LONGMA’s Quality Assurance System

LONGMA maintains a world-class laboratory equipped with state-of-the-art instruments for testing ASTM A671 EFW pipes. Every pipe is tested and certified before delivery.

| Equipment | Function |

| Optical Spectrometer | Analyzes chemical composition accurately. |

| Universal Testing Machine | Measures tensile and yield strength. |

| Automatic Ultrasonic Testing System | Detects weld and internal defects. |

| Hydrostatic Pressure Tester | Evaluates pressure performance and sealing. |

Each production batch is supported by an MTC (Mill Test Certificate), ensuring full transparency and traceability.

Global Applications of ASTM A671 EFW Pipes

ASTM A671 EFW pipes are extensively used in oil & gas, power plants, chemical processing, and marine engineering. Their ability to perform under medium to high-pressure conditions makes them ideal for energy transmission systems.

LONGMA’s ASTM A671 CC60 and CC70 pipes have been successfully installed in major international projects across the Middle East, Africa, Southeast Asia, and South America, earning a reputation for durability and reliability.

Conclusion: LONGMA — Your Reliable Partner in Steel Pipe Manufacturing

With advanced facilities, a robust ASTM A671 production system, and unwavering quality control, LONGMA has become a trusted global supplier of electric fusion welded pipes.

Whether you need ASTM A671 CC60, CC65, or CC70, LONGMA provides customized solutions that meet global standards and exceed expectations.

Choosing LONGMA means choosing quality, reliability, and long-term value.