In modern industrial piping systems, selecting high-quality steel pipes is essential to ensure long-term safety and reliable operation. ASTM A671 pipe is widely used in petroleum, natural gas, chemical, and power generation industries due to its strict requirements for mechanical properties and chemical composition.

This article provides a comprehensive analysis of ASTM A671 steel pipes, including their mechanical performance, chemical composition, testing methods, and application fields. It also highlights LONGMA’s manufacturing and quality control advantages, offering valuable insights for project engineers and procurement specialists.

Overview of ASTM A671 Standard

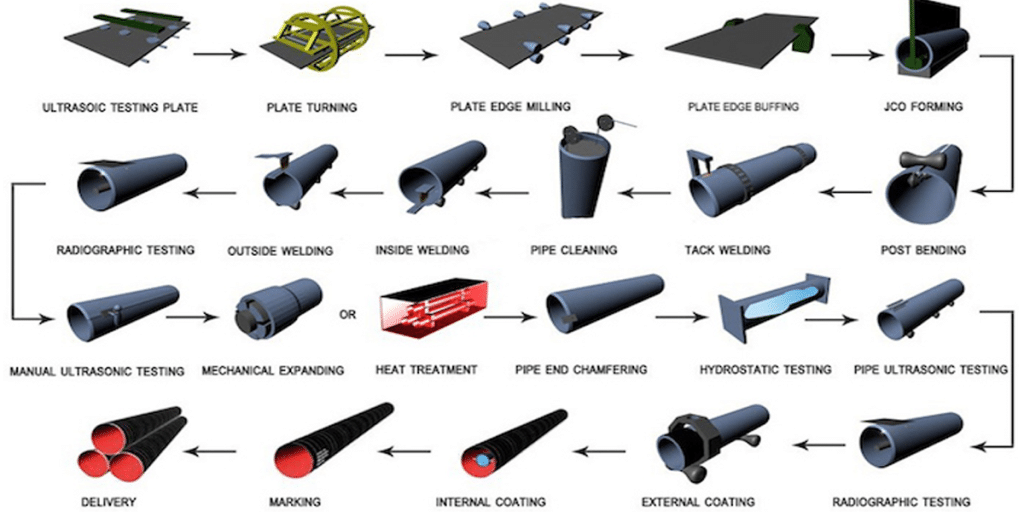

ASTM A671 is a specification developed by the American Society for Testing and Materials (ASTM) for Electric Fusion Welded (EFW) steel pipes used in pressure and high-temperature services.

It includes several grades such as CC60, CC65, and CC70, each designed for different pressure and temperature environments.

| Grade | Characteristics | Typical Application |

| CC60 | Moderate strength and excellent weldability | Low to medium pressure pipelines |

| CC65 | Balanced strength and toughness | Petroleum and chemical processing |

| CC70 | High strength and superior pressure resistance | High-temperature, high-pressure systems |

Mechanical Properties Comparison

Mechanical performance determines the reliability and safety of a steel pipe in service. The following table summarizes the key mechanical properties of ASTM A671 steel pipes:

| Property | CC60 | CC65 | CC70 | Reference Standard |

| Tensile Strength (psi) | 58,000 | 65,000 | 70,000–80,000 | ASTM A671 |

| Yield Strength (psi) | 30,000 | 35,000 | 40,000 | ASTM A671 |

| Elongation (%) | ≥20 | ≥20 | ≥18 | ASTM A370 |

| Impact Toughness (ft·lbf at -20°C) | 15 | 20 | 25 | ASTM E23 |

Performance Summary:

- CC70grade offers higher tensile and yield strength, ideal for high-pressure and thermal systems.

- CC60provides excellent workability and weldability, suitable for medium-pressure pipelines.

- All grades maintain elongation above 18%, ensuring good ductility and resistance to brittle fracture.

Chemical Composition Analysis

The chemical composition of ASTM A671 pipe determines its strength, ductility, and corrosion resistance.

Below is a comparison of chemical ranges for each grade:

| Element | CC60 | CC65 | CC70 | Function |

| Carbon (C) | 0.24–0.28 | 0.26–0.30 | 0.28–0.30 | Increases hardness and strength |

| Manganese (Mn) | 0.70–1.00 | 0.80–1.35 | 1.00–1.40 | Improves toughness and wear resistance |

| Silicon (Si) | 0.15–0.50 | 0.20–0.50 | 0.25–0.60 | Enhances oxidation resistance |

| Phosphorus (P) | ≤0.035 | ≤0.035 | ≤0.035 | Reduces brittleness |

| Sulfur (S) | ≤0.035 | ≤0.035 | ≤0.035 | Prevents cracking |

| Chromium (Cr) / Molybdenum (Mo) | Optional | Optional | Commonly added | Improves high-temperature performance |

Composition Insights:

- As grade increases, carbon and manganese content rise, resulting in higher strength.

- Cr-Mo alloyingin CC70 enhances high-temperature resistance and corrosion protection.

- Controlled low levels of Pand S ensure excellent weld integrity and ductility.

Comparison: ASTM A671 vs A672 vs A691

| Specification | ASTM A671 | ASTM A672 | ASTM A691 |

| Manufacturing Process | EFW (Electric Fusion Welded) | EFW | EFW |

| Base Plate Type | Carbon or low alloy steel | Pressure vessel quality steel | Cr-Mo alloy steel |

| Typical Application | Oil, gas, and heat pipelines | High-pressure steam pipelines | High-temperature boiler tubes |

| Common Grades | CC60 / CC65 / CC70 | CL20 / CL22 / CL25 | 1¼Cr-½Mo / 2¼Cr-1Mo |

| Max. Service Temperature | 450°C | 480°C | 600°C+ |

Conclusion:

- ASTM A671 pipeoffers the most balanced cost-performance ratio for general industrial use.

- For extremely high-temperature or high-pressure conditions, ASTM A691is more suitable.

- In most medium-to-high pressure projects, ASTM A671 CC65or CC70 provides optimal reliability and economy.

Testing and Quality Assurance

LONGMA implements a comprehensive quality control system to ensure every ASTM A671 pipe meets international standards.

| Test Type | Standard | Description | Purpose |

| Chemical Analysis | ASTM E415 | OES spectrochemical testing | Verify element composition |

| Tensile Test | ASTM E8/E8M | Measures tensile, yield, and elongation | Confirm mechanical strength |

| Impact Test | ASTM E23 | Charpy V-notch impact energy | Assess low-temperature toughness |

| NDT (Ultrasonic & Radiographic) | ASTM E213 / E309 | Detect weld and wall defects | Ensure pipe integrity |

| Hydrostatic Test | ASTM A530 | 100% hydrostatic inspection | Validate sealing and pressure resistance |

LONGMA provides full Mill Test Certificates (MTCs) and supports third-party inspection for customer assurance.

Applications of ASTM A671 Pipe

| Industry | Application | Key Benefits |

| Oil & Gas | Transmission pipelines, gathering lines | Corrosion resistance and high pressure capability |

| Chemical Industry | Process piping and acid transport lines | Excellent chemical stability |

| Power Generation | Boiler and heat recovery piping | Suitable for high temperature and high stress |

| Infrastructure | Underground pipeline networks | Long service life and structural integrity |

Advantages of LONGMA Brand

- Over 20 yearsof experience in ASTM-compliant steel pipe manufacturing

- Advanced EFW automatic welding technology for uniform weld seams

- Full range of grades (CC60–CC70) with customizable specifications

- In-house laboratory and complete MTCdocumentation

- Global project experience and professional after-sales support

Conclusion

ASTM A671 steel pipe stands out for its reliable mechanical strength, consistent chemical composition, and rigorous quality testing.

For projects seeking a balance between performance and cost, ASTM A671 CC65 and ASTM A671 CC70 grades are highly recommended.

With over two decades of experience, LONGMA is committed to delivering high-quality, tested, and globally certified steel pipe solutions to ensure your project’s long-term success.