- 1. Overview of the ASTM A671 Steel Pipe Manufacturing Process

- 2. Quality Control Procedures for ASTM A671 Steel Pipes

- 3. Application of Non-Destructive Testing (NDT) in ASTM A671 Steel Pipes

- 4. Challenges in the Production and Quality Control of ASTM A671 Steel Pipes

- 5. Future Development Trends of ASTM A671 Steel Pipes

In modern engineering projects, the stability of transported media is closely tied to the safety and reliability of the pipeline itself. Particularly in industries such as power generation, petrochemicals, and natural gas, the quality requirements for pressure-bearing pipes are extremely stringent. Against this backdrop, ASTM A671 steel pipes have become a preferred choice due to their excellent weldability and reliable low-temperature performance! However, many procurement professionals and engineers are still unfamiliar with the detailed ASTM A671 manufacturing process and the rigorous quality control procedures behind it.

This article will guide you through the entire production flow—from raw material selection and welding process control to heat treatment and final inspection. Each step strictly follows the relevant standards to ensure that the pipe maintains high toughness even in cold environments, a performance that is verified through low-temperature impact tests and other critical assessments. We will also explore key aspects of welded steel pipe quality control, including non-destructive testing, dimensional checks, and the overall quality assurance system that ensures each pipe meets the demanding requirements of today’s industrial applications!

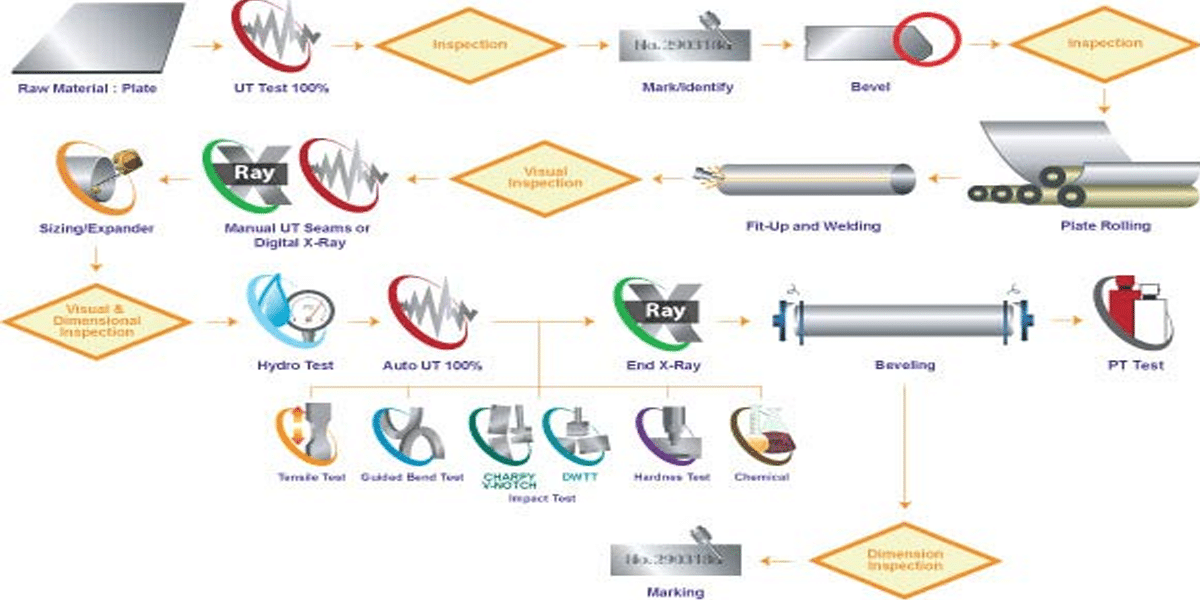

Overview of the ASTM A671 Steel Pipe Manufacturing Process

ASTM A671 steel pipes are widely used in pressure-bearing systems operating in medium to low temperatures. The manufacturing process strictly follows international standards to ensure excellent mechanical properties, weldability, and impact resistance. Below is a typical ASTM A671 manufacturing process overview:

1. Raw Material Selection and Inspection

The process begins with high-quality steel plates or coils that comply with relevant standards such as ASTM A516 or A285. All raw materials undergo chemical composition analysis and mechanical property testing to ensure they meet the requirements for subsequent welding and service performance.

2. Plate Preparation and Beveling

Before forming, steel plates are subjected to surface cleaning, dimensional cutting, and edge beveling. These steps ensure smooth welding and minimize the risk of weld defects. CNC equipment is often used to maintain precision during this phase.

3. Pipe Forming and Welding Procedure

The steel plate is formed into a cylindrical shape and joined using Submerged Arc Welding (SAW)—either with longitudinal or spiral seams. This ASTM A671 welding procedure ensures deep penetration and stable weld formation. During welding, various welded steel pipe quality control measures are applied, including monitoring of welding parameters, filler wire matching, and real-time seam tracking.

4. Post-Weld Heat Treatment (PWHT)

To relieve residual stress from welding and enhance structural stability, most ASTM A671 pipes undergo Post-Weld Heat Treatment. This step is a core part of heat-treated pipe manufacturing and is conducted under controlled temperature and holding time conditions.

5. Non-Destructive Testing and Dimensional Inspection

After welding, the pipe undergoes non-destructive testing (NDT) such as Ultrasonic Testing (UT), Radiographic Testing (RT), or Magnetic Particle Testing (MT) to detect internal flaws like cracks or porosity. Additionally, the pipe’s outer diameter, wall thickness, length, and straightness are checked to ensure compliance with standard and customer specifications.

6. Low-Temperature Impact Test and Final Inspection

Depending on the grade and intended application, some ASTM A671 pipes are subjected to low-temperature impact tests (Charpy V-notch) to verify their toughness in cold environments. Qualified products are then marked, packaged, and documented as part of the comprehensive pipe quality assurance process.

Quality Control Procedures for ASTM A671 Steel Pipes

1. Raw Material Inspection

Strict selection of carbon steel plates that meet ASTM A671 specifications.

Chemical composition analysis and mechanical property tests are conducted to ensure welding suitability.

2. Welding Process Control

Submerged Arc Welding (SAW) is applied according to ASTM A671 welding procedure requirements.

Welding parameters such as temperature, current, voltage, and weld bead size are monitored for consistency.

Welding records are maintained for traceability and quality verification.

3. Heat Treatment Process

Pipes undergo normalizing, tempering, or normalize-tempering treatment depending on the grade.

This heat-treated steel pipe manufacturing step eliminates residual stress and enhances toughness and structural stability.

4. Mechanical Testing & Low-Temperature Impact Test

Finished pipes are subjected to tensile, bending, and hardness tests.

Low-temperature impact testing (e.g., at -20°C or lower) is performed for applications requiring high toughness in cold environments.

5. Non-Destructive Testing (NDT)

Advanced non-destructive testing for steel pipes such as Ultrasonic Testing (UT), Magnetic Particle Testing (MT), and Radiographic Testing (RT) are applied.

These methods ensure internal and weld integrity, free from defects or discontinuities.

6. Dimensional and Visual Inspection

Verification of outside diameter, wall thickness, length, and ovality to meet standard specifications.

Surface inspection to detect any cracks, inclusions, undercuts, or weld spatter.

7. Marking and Quality Documentation

Qualified pipes are marked with production batch, size, and standard information.

A complete steel pipe quality assurance process is maintained through full test reports and traceable documentation.

Application of Non-Destructive Testing (NDT) in ASTM A671 Steel Pipes

In the manufacturing of ASTM A671 welded steel pipes, Non-Destructive Testing (NDT) plays a critical role in ensuring product integrity, weld quality, and service safety. Unlike destructive methods, NDT allows for the detection of internal or surface defects without damaging the pipe structure, making it an essential part of the pipe quality assurance process.

1. Why Is NDT Required for ASTM A671 Pipes?

ASTM A671 pipes are commonly used in high-demand applications such as pressure pipelines, power plants, and oil & gas transmission systems, where weld integrity is crucial for safe operation. Therefore, multiple NDT techniques must be applied—especially after welding and heat treatment—to ensure the absence of internal flaws such as cracks, slag inclusions, porosity, or lack of fusion.

2. Common Non-Destructive Testing Methods

According to ASTM A671 specifications and client requirements, the following non-destructive testing methods are typically used during production:

Ultrasonic Testing (UT)

High-frequency sound waves are transmitted through the weld area to detect internal reflections. This method is highly efficient and widely used for detecting internal defects like porosity or slag.

Radiographic Testing (RT)

X-rays or gamma rays are used to produce clear images of the weld zone, allowing precise identification of internal defects. RT is a standard method for evaluating welded pipe quality, especially in high-pressure systems.

Magnetic Particle Testing (MT)

Suitable for ferromagnetic materials, MT detects surface and near-surface linear defects such as cracks, especially in the weld zone.

Penetrant Testing (PT)

Applied to non-magnetic materials or for surface-breaking defects, PT reveals tiny cracks or pinholes by using capillary action of dye penetrants.

3. Testing Stages and Coverage

Within the ASTM A671 manufacturing process, NDT is performed at several critical stages:

After welding, before heat treatment: Preliminary inspection to identify major defects in the weld seam.

After heat treatment, before delivery: Final inspection to ensure that the ASTM A671 welding procedure and post-weld heat treatment did not introduce or worsen defects.

Per customer specification: Some projects may require 100% NDT scanning, especially on critical pipe segments.

4. The Role of NDT in Quality Control

NDT is not only a detection method but also a crucial component of the pipe quality control and assurance process. Effective NDT implementation provides the following benefits:

Early detection of potential risks, reducing the chance of failure during service;

Enhanced product consistency and reliability;

Compliance with third-party inspection and international engineering standards.

Challenges in the Production and Quality Control of ASTM A671 Steel Pipes

ASTM A671 is a critical standard for electric-fusion-welded carbon steel pipes, widely used in the transportation of oil, gas, high-pressure fluids, and in power generation systems. Due to the demanding conditions under which these pipes are often used—such as high pressure, high temperature, or subzero environments—the ASTM A671 manufacturing process and subsequent quality control procedures face several technical and operational challenges. Below is an overview of the key issues involved.

1. Stability of the Welding Procedure

ASTM A671 pipes are manufactured using arc welding techniques such as SAW (Submerged Arc Welding). The quality of the weld directly affects the overall performance of the pipe. Maintaining consistency in the ASTM A671 welding procedure—including welding parameters, heat input, and filler material selection—is critical. Any deviation may lead to welding defects such as lack of fusion, slag inclusion, or cracking, which compromise pipe integrity.

2. Uniformity in Heat Treatment

Post-weld heat treatment (e.g., normalizing, tempering) is required to optimize mechanical properties. However, due to the large diameter and varying wall thicknesses of these pipes, achieving uniform heating and cooling can be difficult. Uneven temperature distribution may affect the microstructure and mechanical performance, making heat-treated pipe manufacturing a complex technical task.

3. Meeting Low-Temperature Impact Requirements

For applications in cold climates or low-temperature fluid transport, ASTM A671 steel pipes must pass low-temperature impact tests to verify toughness under specified conditions. Since the base metal, weld seam, and heat-affected zone (HAZ) may have different impact properties, it is critical to ensure that the entire welded structure performs reliably. This requires careful material selection, precise welding techniques, and a well-controlled heat treatment regime.

4. High Standards for Non-Destructive Testing (NDT)

Given the strict inspection standards of many international projects, basic UT or RT may not suffice. Some customers even demand 100% non-destructive testing of steel pipes, requiring high-sensitivity equipment, certified inspectors, and more advanced testing procedures. This increases production cost and lead time, posing significant operational challenges.

5. Traceability and Quality Management Challenges

As quality documentation requirements grow, ASTM A671 pipes must not only meet mechanical property specifications, but also provide complete traceable production records—including material heat numbers, welding logs, heat treatment data, and NDT reports. A robust pipe quality control system is essential, especially for high-volume orders and time-sensitive projects. Enhancing digital documentation and process traceability is becoming a key competitive advantage for manufacturers.

Future Development Trends of ASTM A671 Steel Pipes

With the global energy structure evolving and continuous infrastructure development, ASTM A671 steel pipes, as high-performance welded steel products, are experiencing ongoing technological advancements and expanding applications. The future of this field is expected to follow these key development trends:

1. Smart Manufacturing Drives Upgrades in the ASTM A671 Manufacturing Process

Traditional welded steel pipe production lines are gradually being replaced by automated and intelligent equipment. Future manufacturing will emphasize data-driven operations and equipment integration to enhance production efficiency and consistency. For example, IoT-based welding monitoring systems can provide real-time tracking of welding temperature, speed, and stress, effectively reducing human error and improving overall welded steel pipe quality control.

2. Continuous Optimization of Heat Treatment and Microstructure Control

As users demand higher steel pipe performance, heat-treated pipe manufacturing will adopt advanced control strategies such as multi-zone temperature control and AI-assisted temperature regulation. These improvements aim to achieve more uniform microstructures and enhanced low-temperature toughness, especially for projects with stringent low-temperature impact test requirements, raising the technical threshold further.

3. Intelligent and High-Precision Development in Non-Destructive Testing (NDT)

Future non-destructive testing (NDT) technologies for steel pipes will increasingly incorporate automated ultrasonic testing, phased array ultrasonic testing (PAUT), and time-of-flight diffraction (TOFD). Combined with AI algorithms, these techniques enable rapid detection and automatic identification of weld defects, ensuring higher product reliability.

4. International Standards Becoming More Refined and Environmentally Oriented

Standards such as ASTM are evolving toward higher safety, consistency, and environmental sustainability. Future revisions of ASTM A671 may include clearer requirements on welding material compatibility, weld microstructure standards, and guidelines for carbon emission and energy consumption control. This trend will drive manufacturers toward greener production practices.

5. Expanding Application Scenarios and Increasing Demand for Customization

Beyond traditional sectors like oil, gas, and power, ASTM A671 steel pipes are extending into emerging fields such as LNG cryogenic transport, hydrogen energy pipelines, and geothermal fluid conveyance. These applications demand higher toughness, corrosion resistance, and traceability, pushing manufacturers to accelerate the development of higher-grade and better-adapted products, while building flexible delivery systems and personalized production capabilities.

With continuous technological advancements and increasingly diversified market demands, the manufacturing process and quality control systems of ASTM A671 steel pipes will keep evolving and improving. Intelligent welding techniques, refined heat treatment methods, and advanced non-destructive testing technologies will provide a solid foundation for the performance and reliability of steel pipe products. Facing more stringent low-temperature impact tests and increasingly comprehensive international standards, manufacturers must strengthen their overall quality assurance processes while actively promoting green manufacturing and customized services to maintain a competitive edge in the market. Looking ahead, ASTM A671 welded steel pipes will play a vital role in more critical industries, becoming a key support for industrial upgrading and sustainable development. We warmly welcome professionals and stakeholders from all sectors to visit and provide guidance, joining us in witnessing innovation and progress within the industry!