- 1. Overview of ASTM A53 Grade B Standard

- 2. Effect of Temperature on the Strength of ASTM A53 Grade B Pipes

- 3. Pressure Derating and Design Considerations

- 4. Comparison with Other Relevant Standards

- 5. LONGMA’s Manufacturing and Testing Capabilities

- 6. Conclusion: Safety and Reliability Begin with the Right Pipe

In industrial fluid transportation systems, ASTM A53 Grade B pipes—commonly known as ASTM A53 B—are widely used across the oil and gas, water supply, power generation, and chemical industries for their excellent strength, weldability, and versatility.

However, one crucial factor often overlooked by engineers and buyers during material selection is the temperature and pressure derating factor. This parameter directly affects the pipe’s service life, operational safety, and cost efficiency.

This article provides a comprehensive explanation of how temperature and pressure influence the mechanical behavior of ASTM A53 Grade B pipes, along with design principles and practical recommendations based on international engineering standards.

Overview of ASTM A53 Grade B Standard

According to ASTM A53/A53M, ASTM A53 Grade B is a carbon steel pipe available in seamless (Type S) or electric-resistance welded (Type E) form, primarily used for the transmission of steam, water, gas, and other liquids, as well as for structural purposes.

| Property | ASTM A53 Grade B Requirement |

| Tensile Strength | ≥ 415 MPa (60,000 psi) |

| Yield Strength | ≥ 240 MPa (35,000 psi) |

| Elongation | ≥ 20% |

| Type | Type E (ERW) or Type S (Seamless) |

| Size Range | DN 15–DN 600 (NPS 1/2–24) |

| Typical Applications | Water pipelines, gas lines, steam systems, and structural supports |

Effect of Temperature on the Strength of ASTM A53 Grade B Pipes

(1)Elevated Temperature Reduces Material Strength

The base material of ASTM A53 Grade B is medium-carbon steel, whose strength decreases progressively with rising temperature.Once the temperature exceeds room temperature (approximately 25°C), dislocation movement and atomic diffusion within the metal’s crystal lattice intensify, causing both yield strength and tensile strength to drop.

This is why high-temperature system design must apply a temperature derating factor to adjust the pipe’s allowable design pressure, as required by ASME and ASTM standards.

(2)Reference Data from ASTM/ASME Standards

The following table shows the recommended temperature derating factors for ASTM A53 Grade B pipes based on ASME B31.3 and ASTM A53 Appendix:

| Temperature (°C) | Derating Factor (%) | Strength Retention Ratio |

| 25°C | 100% | 1.00 |

| 100°C | 95% | 0.95 |

| 200°C | 90% | 0.90 |

| 300°C | 85% | 0.85 |

| 400°C | 75% | 0.75 |

| 450°C | 68% | 0.68 |

Example:

A pipeline designed for 4.0 MPa at 25°C must be derated by 0.75 when operating at 400°C, resulting in an adjusted allowable pressure of 3.0 MPa.

Pressure Derating and Design Considerations

(1) Definition of Pressure Derating

Pressure derating refers to the reduction in allowable design pressure caused by the loss of material strength at elevated temperatures.

This factor is particularly critical in long-term, high-temperature pipeline operations.

According to ASME B31.1 / B31.3, the design pressure of a pipe can be calculated using the following equation:

P = (2×S×t)/(D – 2×y×t)

Where:

- P= Design Pressure

- S= Allowable Stress (temperature-dependent)

- t= Wall Thickness

- D= Outside Diameter

- y= Weld Joint Factor (Type E = 0.85; Type S = 1.00)

Incorporating derating factors in design calculations helps prevent creep, thermal fatigue, and long-term deformation, thereby ensuring safety margins are maintained.

(2) Differences Between Type E and Type S Pipes

ASTM A53 Grade B is available in two manufacturing types, each suited for specific operating conditions:

| Type | Description | Application Characteristics |

| Type E (ERW) | Electric Resistance Welded | Slightly lower weld strength than base metal; suitable for medium- and low-pressure systems such as water supply and HVAC. |

| Type S (Seamless) | Hot-finished seamless | No weld seam, superior stability under high temperature and high pressure; ideal for steam and high-pressure gas pipelines. |

For systems operating above 350°C, it is recommended to use ASTM A53 Grade B Type S (Seamless) for maximum safety and performance consistency.

Comparison with Other Relevant Standards

| Standard | Equivalent Material | Key Distinctions |

| ASTM A106 Grade B | Seamless carbon steel pipe for high-temperature service | Designed for higher temperatures (up to 450°C); slightly higher yield strength |

| API 5L Grade B | Line pipe for oil and gas transmission | Enhanced requirements for toughness and impact resistance |

| ASTM A53 Grade B | General-purpose structural and conveying pipe | Balanced performance and excellent cost-efficiency |

For long-term high-temperature or pressure-fluctuating systems, a combined ASTM A106/A53 Grade B specification can be used.

At LONGMA, such pipes are subjected to 100% hydrostatic testing and ultrasonic inspection (UT) to meet the highest international safety standards.

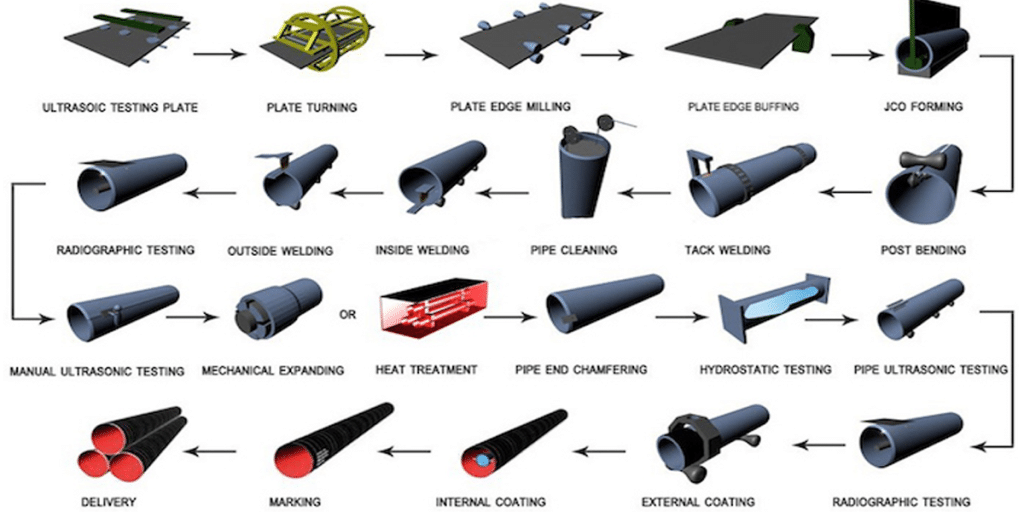

LONGMA’s Manufacturing and Testing Capabilities

With over 20 years of experience in the steel pipe industry, LONGMA adheres to ASTM A53/A53M, ASME B31.3, and ISO 9001 quality management systems.

Our in-house testing laboratory is equipped with advanced temperature-pressure simulation equipment, capable of performing:

- High-temperature creep tests

- Tensile and yield strength validation

- Hydrostatic and pneumatic pressure testing

- Radiographic (RT) and ultrasonic (UT) weld inspection

Every ASTM A53 Grade B steel pipe produced by LONGMA meets or exceeds international requirements.Customers receive a Mill Test Certificate (MTC) and, upon request, third-party inspection reports (BV, SGS, or TÜV), ensuring traceability and confidence in product quality.

Conclusion: Safety and Reliability Begin with the Right Pipe

In high-temperature and high-pressure environments, neglecting the temperature and pressure derating factors of ASTM A53 Grade B pipes can lead to leaks or catastrophic failures.

Choosing LONGMA ASTM A53 Grade B carbon steel pipes, manufactured and tested under strict quality standards, ensures operational stability, extended service life, and reduced maintenance costs throughout your project’s lifecycle.

LONGMA — Your trusted partner for ASTM A53 Grade B pipe manufacturing and engineering solutions.

Contact us today for the latest ASTM A53 Grade B specification sheet (PDF) and a customized project quotation.