- 1. Overview of Common Failures

- 2. Troubleshooting for Each Failure Type

- 3. On-Site Inspection and Testing Checklist

- 4. Quick Failure-Solution Reference Table

- 5. Installation and Construction Recommendations

- 6. Frequently Asked Questions (FAQs)

- 7. LONGMA’s Advantages and Contact Information (Call to Action)

During the installation of ASTM A53 pipes, the most common issues include weld defects (especially in ERW series), joint/flange leakage, deformation caused by buried pipe settlement, coating/galvanization damage, and electrochemical corrosion. Most of these issues can be prevented and resolved through: (1) strict factory inspection in accordance with ASTM A53 and on-site Non-Destructive Testing (NDT, including Ultrasonic Testing/UT, Radiographic Testing/RT, electrical testing, and pressure testing) for acceptance; (2) proper pipe support and backfilling; (3) qualified welding and heat treatment processes; and (4) reasonable anti-corrosion and cathodic protection measures.

Overview of Common Failures

- Weld-related issues: Cold welding, lack of fusion, slag inclusion, and Selective Seam Weld Corrosion

- Joint/flange leakage: Seal face damage, insufficient bolt preload, or improper gasket selection

- Pipe deformation and ovalization: Improper hoisting/backfilling or foundation settlement

- Surface/coating damage and corrosion: Damage during transportation/installation, local grounding, or humid-heat environments

- Pipe support or anchorage failure: Stress concentration caused by improper control of thermal expansion/contraction

Troubleshooting for Each Failure Type

Weld Defects (ERW and LSAW Pipes)

- Diagnosis: Visual inspection → Magnetic Particle Testing (MT)/Liquid Penetrant Testing (PT) → UT/RT to locate defects. For old low-frequency ERW pipes, focus on detecting cold welding and seam area corrosion.

- Treatment: For repairable defects, cut and rework the weld in accordance with construction specifications, followed by subsequent NDT. For severe defects, replace the pipe section and conduct a hydrostatic test as required by ASTM A53.

- Prevention: Source qualified ERW/LSAW pipes from reputable suppliers; require manufacturers to perform in-line electrical testing, factory UT, and hydrostatic testing before delivery.

Joint and Flange Leakage

- Diagnosis: Reproduce the leakage location via pneumatic/hydrostatic testing; inspect gasket surfaces, bolt torque, and flange flatness.

- Treatment: Replace with qualified gaskets, cross-tighten bolts to the specified torque, and conduct a second pressure test. If necessary, regrind the flange surface or replace the flange.

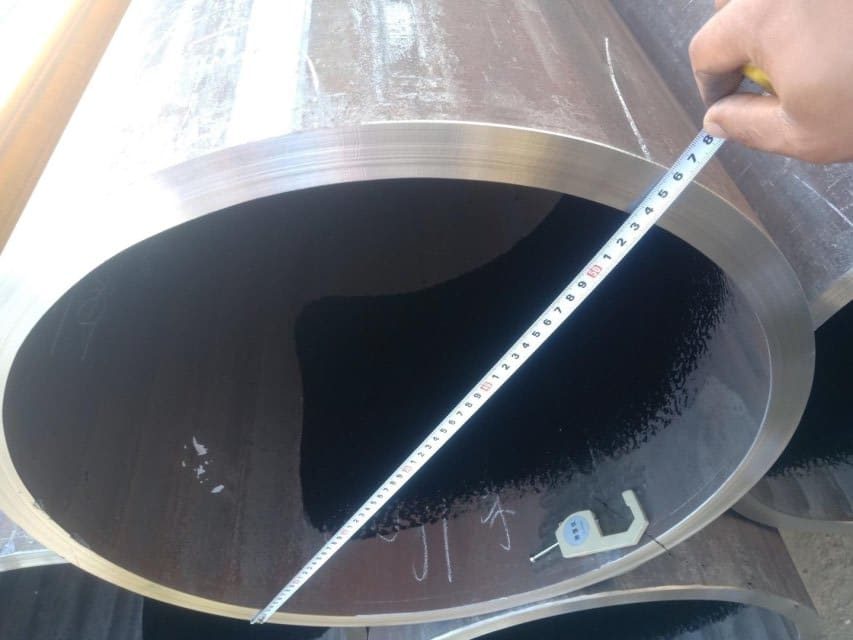

Buried Pipe Settlement and Deformation

- Diagnosis: Measure pipe top elevation differences, local stress concentration, cracks, or deformation.

- Treatment: Perform partial backfilling with layered compaction; replace supports or add anchors if necessary. Evaluate whether damaged pipe sections need replacement.

Coating/Galvanization Damage and Corrosion

- Diagnosis: Visual inspection, coating thickness gauge, holiday test, and local corrosion detection.

- Treatment: For small areas, perform mechanical rust removal and touch up with epoxy/polyethylene coating. For severe corrosion, replace the pipe and analyze the root cause of corrosion (electrochemical, stress, medium, etc.).

- Prevention: Adopt protective measures during transportation/installation (e.g., wooden sleepers/soft pads); repair coatings on-site; design a cathodic protection system if necessary.

On-Site Inspection and Testing Checklist

- Verify Material Test Certificate (MTC), dimensions, and steel grade

- Visual inspection (dents, scratches, weld appearance)

- Weld NDT: MT/PT + UT/RT (per contract requirements)

- Coating integrity testing: Thickness measurement and holiday test

- Joints/flanges: Torque records, second pressure test (hydrostatic or pneumatic)

- Buried pipelines: Backfill compaction records and settlement observation points

Quick Failure-Solution Reference Table

| Failure | Key Symptoms | Possible Causes | Temporary On-Site Treatment | Long-Term Prevention |

| Weld cracks/leakage | Leakage or cracks at welds | Poor welding parameters, cold welding | Cut and rework; conduct NDT | In-factory electrical testing + factory UT/hydrostatic testing |

| Flange leakage | Water seepage/bubbles at joints | Damaged gasket, loose bolts | Replace gasket; cross-tighten to torque | Use qualified gaskets; record bolt torque |

| Pipe deformation | Pipe top depression/ovalization | Improper backfilling, settlement | Excavate partially; restore and rebackfill | Layered backfilling and compaction per specifications |

| Coating damage | Rust spots exposing base metal | Damage during transportation/installation | Touch up with anti-corrosion paint | On-site protection; holiday testing |

| Selective seam weld corrosion | Corrosion in weld grooves | Different microstructures in weld zone, electrochemical differences | Partial repair or replacement | Use high-quality welding; perform post-weld treatment |

Installation and Construction Recommendations

- Cutting and Acceptance: Verify MTC and appearance; record batch numbers and pipe section IDs.

- Hoisting: Use dedicated lifting equipment; avoid direct pressure on the pipe body from lifting lugs to prevent dents.

- Welding and Heat Treatment: Ensure welders and welding processes are qualified; perform Post-Weld Heat Treatment (PWHT) if required by the project.

- Backfilling: Use stone-free granular soil; conduct layered backfilling and compaction; set up settlement observation points.

- Quality Documentation: Retain records of welding, pressure testing, NDT, and coating testing for future traceability.

Frequently Asked Questions (FAQs)

Q: Can minor weld leakage be repaired?

A: Yes. Repairs can be done by cutting and reworking the weld, or grinding the weld flat and performing local repair welding. After repair, corresponding NDT and pressure testing must be conducted to confirm integrity.

Q: Are ERW pipes more prone to weld corrosion?

A: Historically, low-frequency ERW pipes did have more issues with selective seam corrosion. However, quality control and NDT for modern high-frequency ERW and LSAW pipes can effectively reduce this risk.

LONGMA’s Advantages and Contact Information (Call to Action)

With over 20 years of experience in steel pipe manufacturing, LONGMA specializes in producing ERW and LSAW round pipes. We comply with ASTM A53 factory inspection requirements (including factory UT/electrical testing, hydrostatic testing, and MTC provision) and offer the following for engineering projects:

- Strict production and factory inspection processes to reduce risks of welds and internal defects;

- Project-level technical support: Construction guidance, NDT testing recommendations, and after-sales follow-up;

- Customizable surface treatments (black pipe, hot-dip galvanization, coating) and packaging per customer requirements;

- Stable delivery capacity and flexibility for small-batch orders.

For technical support, samples, or quick quotes, please use the contact form on our website or send an inquiry to our business email (insert your contact information here). LONGMA will assist you within the shortest possible time.

Note: The inspection and treatment methods provided in this document are based on ASTM A53 requirements and industry practices (including weld NDT, factory hydrostatic testing, and on-site pressure testing). For project implementation, it is recommended to refer to project specifications (owner/construction/design documents) and coordinate with testing institutions.