- 1. What Are ASTM A53 Pipes?

- 2. Key Differences Between ASTM A53 Grade A and Grade B

- 3. Comparison of Chemical Composition

- 4. Comparison of Mechanical Properties

- 5. Production Processes: Combination of ERW and LSAW

- 6. Typical Applications of ASTM A53 Grade A and Grade B

- 7. Grade A: Ductility as Priority

- 8. Grade B: Strength as Priority

- 9. Why Choose LONGMA’s ASTM A53 Pipes?

In the steel pipe industry, ASTM A53 pipes are among the most widely used carbon steel pipe standards. Whether in oil and gas systems, water supply and drainage systems, or structural engineering, A53 pipes are widely adopted due to their excellent weldability, strength, and cost-effectiveness.

However, many customers often wonder: What exactly is the difference between ASTM A53 Grade A and Grade B? This article will conduct an in-depth analysis from multiple perspectives, including chemical composition, mechanical properties, production processes, and application scenarios, and provide reference for your project selection.

What Are ASTM A53 Pipes?

ASTM A53 is a carbon steel pipe standard developed by the American Society for Testing and Materials (ASTM), applicable to round steel pipes manufactured by welding, galvanizing, or seamless processes. Its typical applications include:

- Fluid transportation (e.g., water, gas, steam, oil);

- Structural support (construction and infrastructure);

- Mechanical and engineering purposes.

Key Differences Between ASTM A53 Grade A and Grade B

The ASTM A53 standard is divided into two grades: Grade A and Grade B. The differences between them mainly lie in chemical composition and mechanical properties, which further lead to variations in their applications.

-

Comparison of Chemical Composition

| Element | Grade A | Grade B |

| Carbon (C) | ≤ 0.25% | ≤ 0.30% |

| Manganese (Mn) | ≤ 0.95% | ≤ 1.20% |

| Phosphorus (P) | ≤ 0.05% | ≤ 0.05% |

| Sulfur (S) | ≤ 0.058% | ≤ 0.058% |

| Copper (Cu) | ≤ 0.40% | ≤ 0.40% |

| Nickel (Ni) | ≤ 0.40% | ≤ 0.40% |

| Chromium (Cr) | ≤ 0.40% | ≤ 0.40% |

| Molybdenum (Mo) | ≤ 0.15% | ≤ 0.15% |

As shown in the table, Grade B has higher carbon and manganese contents, so its strength is superior to that of Grade A.

-

Comparison of Mechanical Properties

| Property | Grade A | Grade B |

| Yield Strength (min) | 30,000 psi (205 MPa) | 35,000 psi (240 MPa) |

| Tensile Strength (min) | 48,000 psi (330 MPa) | 60,000 psi (415 MPa) |

| Elongation (2-inch gauge) | ≥ 35% | ≥ 30% |

Conclusion: Grade B has higher strength than Grade A, while Grade A has better ductility.

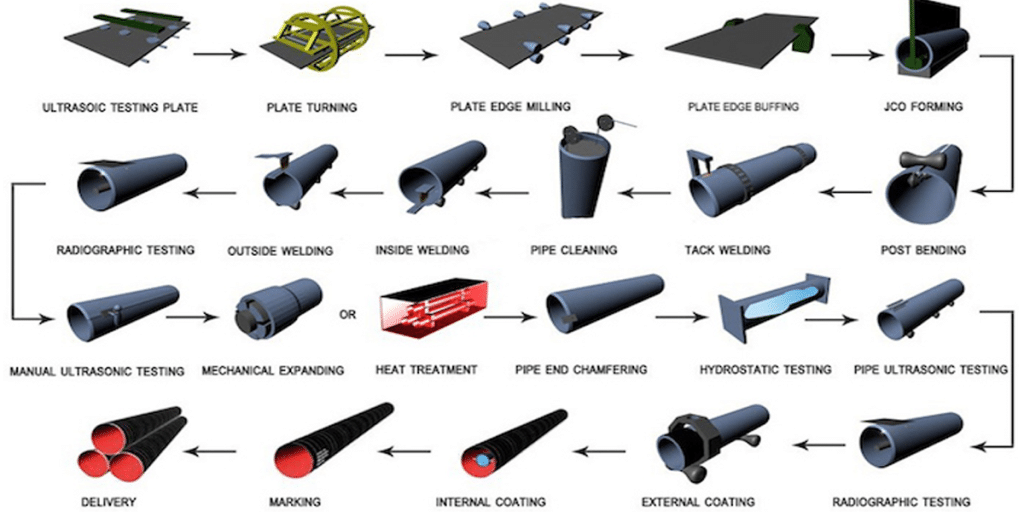

Production Processes: Combination of ERW and LSAW

ASTM A53 pipes can be manufactured through various processes, including seamless pipes, Electric Resistance Welded (ERW) pipes, and Longitudinal Submerged Arc Welded (LSAW) pipes.

- ERW (Electric Resistance Welded) Pipes: Suitable for mass production of small and medium-diameter pipes, with uniform welds, and applicable to fluid transportation.

- LSAW (Longitudinal Submerged Arc Welded) Pipes: Usually used in large-diameter, high-strength scenarios, such as cross-border oil transmission pipelines and structural support.

As a steel pipe manufacturer with over 20 years of experience, LONGMA has significant advantages in the production of ERW and LSAW round pipes, ensuring that products meet the strict requirements of ASTM A53.

Typical Applications of ASTM A53 Grade A and Grade B

-

Grade A: Ductility as Priority

- Water supply and drainage systems

- Light structural components

- General engineering purposes

-

Grade B: Strength as Priority

- High-pressure transmission pipelines (steam, oil, natural gas)

- Bridge and structural support

- Machinery manufacturing and heavy engineering

Summary: If your project emphasizes pressure resistance and load-bearing capacity, it is recommended to choose ASTM A53 Grade B; if your project focuses more on weldability and ductility, Grade A is also an ideal choice.

Why Choose LONGMA’s ASTM A53 Pipes?

As an enterprise with over 20 years of experience in steel pipe manufacturing, LONGMA not only strictly implements international standards such as ASTM A53, EN10219, and API 5L but also provides customized solutions according to customers’ project needs. Our advantages include:

- Professional production lines: Advanced ERW and LSAW round pipe equipment to meet the needs of different diameters and thicknesses.

- Strict quality control: Full-process implementation of non-destructive testing (UT, RT), hydrostatic testing, and chemical and mechanical property testing.

- International project experience: Products are exported to Southeast Asia, the Middle East, Europe, and other regions, and widely used in oil and gas, infrastructure, and industrial engineering.

- Fast delivery and after-sales service: A complete logistics system and a professional technical support team to ensure customers have no worries.

If you are looking for a reliable supplier of ASTM A53 Grade A or Grade B pipes, please contact us immediately—LONGMA will become your most trustworthy partner.