In modern energy, chemical, and power industries, ASTM A671 steel pipe is widely used in medium- and high-temperature transport systems due to its excellent pressure resistance and weldability. The standard primarily covers Electric Fusion Welded (EFW) carbon steel pressure pipes, especially ASTM A671 EFW pipe, which demonstrates reliable and stable performance in boilers, heat exchangers, petrochemical facilities, and long-distance pipelines. This article explores the welding technology, inspection methods, and how LONGMA ensures global customer trust through rigorous quality control.

ASTM A671 Standard and Material Fundamentals

ASTM A671 material specifies requirements for welded steel pipes manufactured from pressure vessel steel plates using EFW technology. Different grades, such as ASTM A671 GR CC60 CL22, represent variations in chemical composition, heat treatment, and strength levels.

| Feature | Description |

| Grade CC60 | Typically uses ASTM A516 Gr.60 steel plate |

| Class 22 | Post-weld heat treatment (PWHT) enhances crack resistance and toughness |

| EFW Welding | Ensures weld metal density and pressure resistance |

This design allows ASTM A671 EFW pipe to perform well in both high- and low-temperature environments, making it suitable for offshore platforms, thermal energy equipment, and oil & gas storage and transport systems.

ASTM A671 Welding Technology

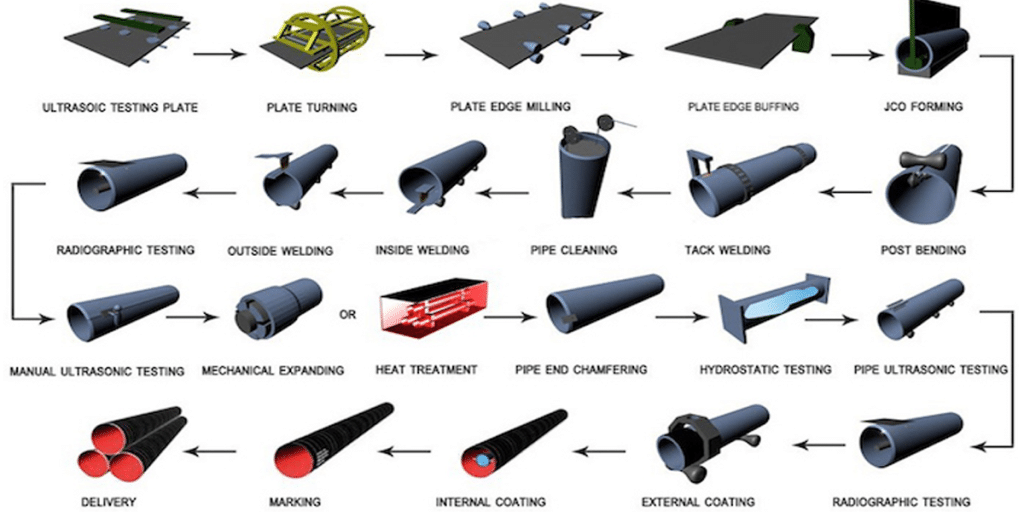

The manufacturing process of ASTM A671 pipes relies on Electric Fusion Welding (EFW). Steel plates are formed into cylinders and welded under a high-temperature electric arc. Compared to submerged arc welding or resistance welding, EFW offers:

| Advantage | Description |

| Deep Weld Penetration | Arc energy is concentrated, reducing slag inclusions and porosity |

| Suitable for Thick-Walled Pipes | Ideal for ASTM A671 GR CC60 CL22 and other mid-to-high-grade steels |

| Consistent Weld Quality | Automated control of current and speed ensures uniformity |

| Controlled Post-Weld Heat Treatment | PWHT reduces residual stress and improves ductility |

LONGMA’s automated EFW welding lines with precise temperature control guarantee defect-free welds for every ASTM A671 EFW pipe, compliant with the latest ASTM A671 standard.

Weld and Base Material Inspection Methods

Post-weld inspection is critical to ensure quality. ASTM A671 (Chapter 16) specifies the following methods:

| Inspection Method | Purpose |

| Radiographic Testing (RT) | Detects internal weld defects such as cracks, porosity, or slag inclusions |

| Ultrasonic Testing (UT) | High-frequency waves detect discontinuities within welds, crucial for ASTM A671 material quality control |

| Hydrostatic Test | Each ASTM A671 EFW pipe is pressure-tested above design pressure to verify durability |

| Mechanical Testing | Tensile, impact, and bending tests ensure ASTM A671 GR CC60 CL22 maintains strength under high- and low-temperature conditions |

All inspections are conducted in LONGMA’s ISO/IEC 17025-accredited in-house laboratory, providing reliable, third-party-recognized results.

LONGMA Quality Control and Brand Strength

LONGMA strictly adheres to international standards and customer specifications during the production of ASTM A671 material. Every step—from raw material sourcing and plate acceptance to weld parameter control and final inspection—is fully traceable.

| Quality Control Feature | Details |

| In-House Lab | Advanced spectrometer, universal testing machine, and automated UT equipment |

| Digital Monitoring | Real-time recording of welding current, voltage, and speed |

| Documentation | Provides MTC (Material Test Certificates), NDT reports, and third-party certifications |

This transparent quality management allows customers to fully trust LONGMA’s manufacturing capabilities and data traceability when choosing ASTM A671 EFW pipe.

Conclusion: Stable, Reliable, and Trustworthy Solutions

With increasing demand for energy transport and high-strength pipelines, ASTM A671 GR CC60 CL22 steel pipes have become the preferred material for offshore projects, thermal power stations, and chemical systems due to their superior weldability, mechanical strength, and comprehensive inspection process.

As a leading Chinese welded steel pipe manufacturer, LONGMA not only provides a full range of ASTM A671 EFW pipe but also offers rigorous quality assurance and global delivery experience, delivering stable and reliable engineering solutions for clients worldwide.