- 1. Interpretation of the EN 10219 Standard

- 2. Key Features of EN 10219 Cold-Formed Tubes

- 3. High-Strength, Lightweight Structure

- 4. Versatile Shapes and Flexible Applications

- 5. Excellent Weldability

- 6. Strict Quality Control

- 7. Core Technical Requirements of EN 10219

- 8. Cold-Formed vs Hot-Finished Steel Tubes

- 9. Representative Applications of EN 10219 Tubes

- 10. Domestic Projects:

- 11. International Projects:

- 12. Future Outlook of EN 10219 Standard

- 13. Conclusion

What Is EN 10219? A Complete Guide to Cold-Formed Welded Steel Tubes

In modern architecture and industrial manufacturing, cold-formed steel tubes are widely used in various construction projects due to their lightweight structure, high strength, and flexible processing capabilities. Especially in the European market and international projects, EN 10219 has become an essential technical standard for the production and inspection of cold-formed structural pipes. This article provides an in-depth analysis of the standard’s definition, technical specifications, application scenarios, and real-world case studies both domestically and internationally.

Interpretation of the EN 10219 Standard

EN 10219 is a European standard issued by the European Committee for Standardization (CEN). It specifies the requirements for cold-formed welded structural hollow sections made from non-alloy and fine-grain steels, mainly used for non-pressure applications such as building structures, mechanical components, and transportation facilities. The standard is divided into two parts:

- EN 10219-1: Technical delivery conditions

- EN 10219-2: Tolerances, dimensions, and sectional properties

This standard defines the materials,manufacturing processes,mechanical properties, and inspection requirements for cold-formed tubes, serving as a comprehensive guideline throughout production and application.

Key Features of EN 10219 Cold-Formed Tubes

Tubes manufactured under EN 10219 typically offer the following advantages:

-

High-Strength, Lightweight Structure

After cold forming, the metal grains are compressed, resulting in higher strength than hot-rolled steel of the same cross-section. This makes it suitable for large-span, high-load structures.

-

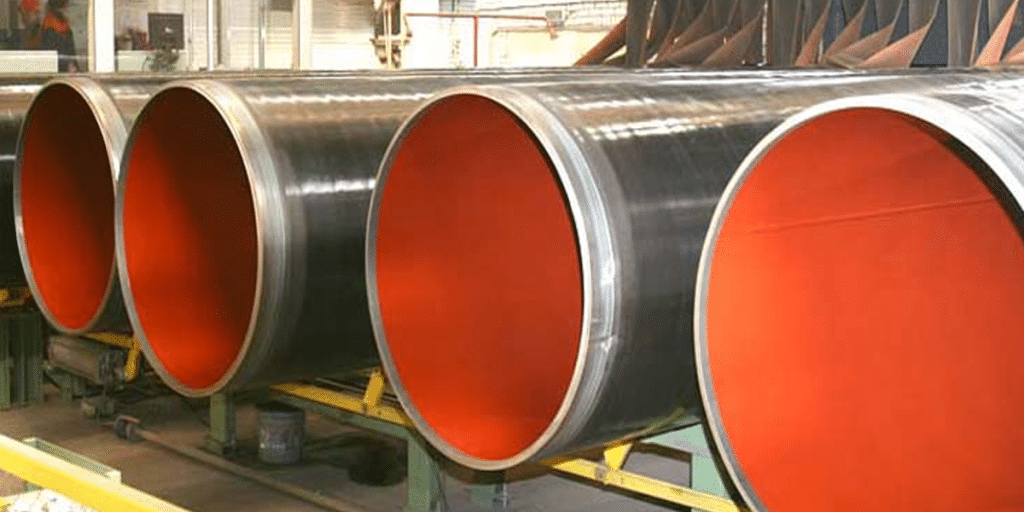

Versatile Shapes and Flexible Applications

Available in circular, square, rectangular, and special cross-sections, enabling optimized structural design. Widely applied in spatial steel structures and prefabricated buildings.

-

Excellent Weldability

Steel grades specified by EN 10219—such as S235JRH, S275J2H, and S355J2H—are all known for their good weldability,ideal for both on-site assembly and prefabrication in factories.

-

Strict Quality Control

The standard includes detailed requirements for chemical composition, mechanical properties, dimensional tolerances, surface quality, and non-destructive testing,ensuring safety and reliability.

Core Technical Requirements of EN 10219

| Element | Description |

| Material | Non-alloy or fine-grain steel, e.g., S355J2H |

| Manufacturing | Cold-formed + high-frequency welding, no heat treatment |

| Outer Diameter | Circular: 21.3–508 mm; Square/Rectangular: up to 500 mm |

| Wall Thickness | Generally 1.5–20 mm |

| Yield Strength | 235–460 MPa (varies by grade) |

| Impact Toughness | Often exceeds 27J at -20°C |

| Testing Methods | Dimensional check, impact test, non-destructive testing |

Cold-Formed vs Hot-Finished Steel Tubes

| Category | Cold-Formed Tubes | Hot-Finished Tubes |

| Forming Temperature | Room temperature (cold processing) | High temperature (hot processing) |

| Surface Quality | Smooth and highly precise | Rough with oxide scale |

| Mechanical Strength | Increased after forming | Generally better ductility |

| Common Standards | EN 10219 | EN 10210 |

EN 10219 is the main standard for cold-formed welded tubes, while EN 10210 is typically applied to hot-finished tubes.

Representative Applications of EN 10219 Tubes

Domestic Projects:

- Xiong’an New Area Green Building Complex (2022)

Promoting green building systems, Xiong’an utilized numerous prefabricated steel structures. Landmark buildings in the core office area adopted S355J2H square and rectangular tubescompliant with EN 10219 as main load-bearing elements, ensuring high strength while enhancing the modern architectural look. - Shenzhen Qianhai Transportation Hub (2021)

This project extensively used cold-formed square tubes as structural supports in underground transfer stations and waiting halls. Rectangular tubes produced per EN 10219 were selected to improve construction efficiency and structural safety.

International Projects:

- Paddington Square Pedestrian Bridge, London, UK (2020)

This bridge employed special-shaped cold-formed tubes designed to meet EN 10219 standards. It delivered excellent mechanical performance while achieving architectural aesthetics, becoming a classic example of integrated structural and architectural design. - China Pavilion, Dubai Expo (2021)

To achieve efficient construction in a desert climate, the pavilion’s steel structure system extensively used cold-formed welded tubes compliant with EN 10219. These offered superior wind resistance and ease of assembly, reducing the construction period and effectively controlling costs.

Future Outlook of EN 10219 Standard

With the continuous advancement of green building, efficient construction, and international engineering cooperation, the cold-formed tube systems represented by EN 10219 are becoming the mainstream in the industry. In the future, this standard may integrate:

- Digital manufacturing (e.g., BIM system integration)

- Traceability management (e.g., steel certification codes)

- Introduction of higher-performance steel grades

Mastering and implementing EN 10219 not only helps companies enter the international market but also significantly improves product quality and market competitiveness.

Conclusion

In conclusion, EN 10219 is a comprehensive, rigorous, and widely applicable standard for cold-formed structural steel tubes. It provides a reliable design and manufacturing basis for various non-pressure structural projects. Whether for urban construction, industrial facilities, or international projects, choosing steel tubes that comply with EN 10219 has become a hallmark of quality and safety in the industry.