In engineering material selection and procurement, S235JR and S275JR are commonly used non-alloy structural steels defined in EN 10025-2. At first glance, they seem similar in application, but they differ clearly in strength grade, chemical composition limits, mechanical properties, and inspection requirements—differences that directly impact structural safety, weldability, and low-temperature performance, determining whether they can be considered “equivalent alternatives.”

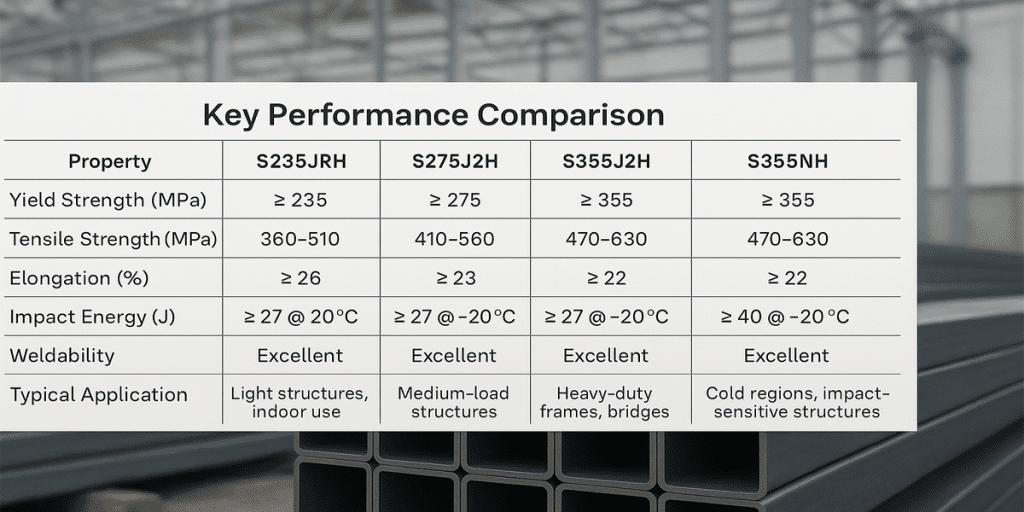

Key Performance Comparison at a Glance

| Parameter | S235JR | S275JR |

| Nominal minimum yield strength | 235 MPa | 275 MPa |

| Tensile strength Rm (typical range) | ~360–510 MPa | ~410–580 MPa (varies with thickness) |

| Chemical composition C (max., typical) | ≤0.17–0.22 (thickness dependent) | ≤0.21–0.25 (thickness dependent) |

| Impact designation (JR) | JR = ≥27 J at +20°C (per standard/contract requirements) | Same JR designation, but higher strength grade |

| Typical applications | General structural parts, frames | Preferred where higher load capacity or reduced sections are required |

The data comes from EN 10025-2 and reputable material property tables.

Note: Actual values vary with thickness, heat treatment, and production batch; always refer to the Mill Test Certificate (MTC).

Why Choose S275JR Over S235JR?

- Higher load-bearing capacity & section optimization

S275JR provides ~40 MPa higher yield strength, allowing reduced section sizes under the same load—saving material and total weight.

- Welding considerations

A slightly higher carbon content or carbon equivalent (CEV) may affect welding procedures and preheating requirements; welding procedure qualification should be reviewed before fabrication.

- Cost trade-off

S275JR typically costs slightly more, but its higher strength reduces material volume or increases structural safety—ideal for designs with stricter load or span requirements.

Recommended Inspection Methods (Reducing Procurement Risk)

To ensure interchangeability and traceability, the following inspection items and acceptance criteria should be written clearly into the contract (LONGMA provides complete testing and MTC internally).

| Inspection Item | Purpose | Standard / Reference | Main Procedures | Acceptance Criteria |

| Chemical analysis (OES) | Verify C, Mn, P, S, Cu, N, CEV compliance | EN 10025-2 + ISO 14284 | Batch/product sampling; OES measurement | Each element ≤ standard/contract limits; values included in MTC |

| Tensile test | Verify Rp0.2, Rm, elongation | ISO 6892-1 / EN 10025-2 tables | Prepare standard samples; room-temperature tensile test | Must meet minimum Rp0.2 and Rm ranges in EN tables; original curves attached |

| Charpy V-notch impact test | Assess resistance to brittle fracture | EN ISO 148-1 / EN 10025-2 | Test 10×10×55 mm specimens at specified temperature | S235JR-JR requires ≥27 J at +20°C (or as specified in contract) |

| Hardness test | Confirm consistency in strength & heat treatment | ISO 6506 / ISO 6508 / ASTM A370 | Surface preparation, load application | Should match expected reference range; no abnormal deviations |

| VT / UT / PT / MT | Detect internal or surface defects | EN 10025-2 + customer QC terms | Ultrasonic/magnetic/penetrant testing | No cracks, laminations, inclusions, or severe defects; record archived |

Recommended: Define sampling frequency, specimen orientation (longitudinal/transverse), acceptance levels, and whether third-party witnessing (BV/SGS/TÜV) is required in the purchasing technical specification.

LONGMA’s Quality Commitment and Capabilities

With over 20 years of manufacturing and exporting experience, LONGMA offers:

- Complete in-house laboratory

Equipped with OES spectrometer, universal tensile machine, Charpy impact tester (multi-temperature), hardness tester, UT/MT/RT instruments—testing strictly per EN/ISO/ASTM, with traceable data.

- Full MTC + optional third-party inspection

Each shipment includes a full MTC (chemical, mechanical, impact, NDT).

Third-party inspection (CNAS/ILAC or customer-specified) is supported.

- Engineering and welding support

Material selection guidance, welding preheat recommendations, and fabrication cautions reduce uncertainty and rework risk during construction.

Practical Suggestions for Buyers

- For high load or reduced section designs → choose S275JR.

- For low-temperature environments → require Charpy test results and specify test temperature in the contract.

- Ensure the contract requires a complete MTC, including:

-

- chemical analysis (OES),

- tensile test data,

- impact energy table,

- NDT records.

- Select suppliers with internal testing capabilities and proven third-party inspection experience, such as LONGMA, to significantly reduce delivery and after-sales risk.

Conclusion — Use Data, Not Assumptions, to Make Material Decisions

Both S235JR and S275JR are mature and reliable structural steels—but they are not interchangeable. Use standardized data, MTC verification, and clear contract inspection requirements to determine whether substitution is acceptable.

LONGMA provides traceable testing capabilities and professional engineering support, turning “material risks” into “engineering assurance.”