What is the pressure rating of API 5L X52 pipe?

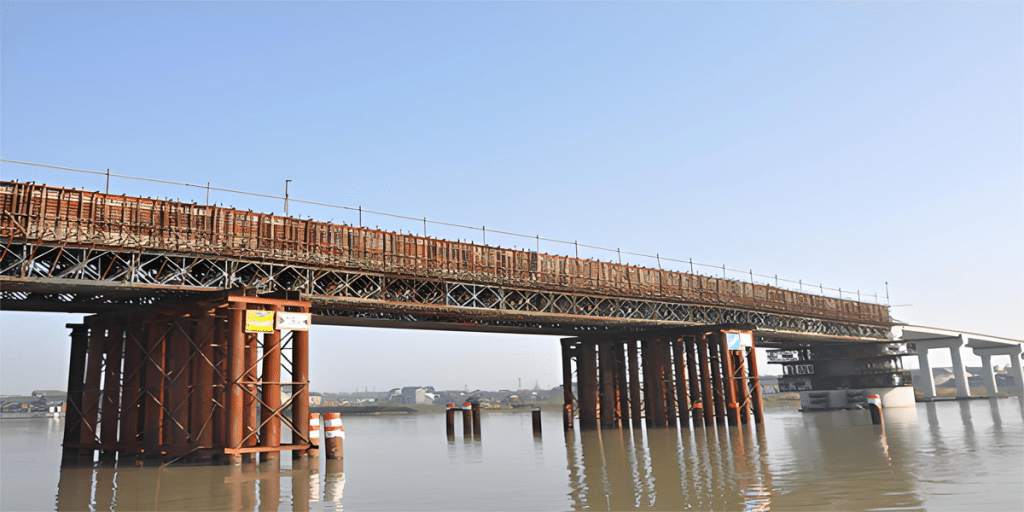

Determining the precise pressure rating of API 5L X52 pipeline requires a comprehensive understanding of its composition, manufacturing standards, and operating parameters. API 5L X52 is a high-strength carbon steel widely used in oil and gas pipelines due to its excellent mechanical properties and corrosion resistance. Let’s gain a deeper understanding of its pressure level from multiple perspectives.

Composition and performance of API 5L X52 steel pipe:

The API 5L X52 pipeline is manufactured with special chemical composition and mechanical properties to ensure reliability and durability under different operating conditions. Its components typically include carbon, manganese, phosphorus, sulfur, silicon, and trace other elements. Mechanical properties, such as yield strength, tensile strength, and elongation, are key factors affecting its pressure rating.

Manufacturing standards of API 5L X52:

The API 5L X52 pipeline is produced according to the standards established by the American Petroleum Institute (API), mainly API Spec 5L. This standard includes the manufacturing requirements for seamless and welded steel pipes for transporting oil, natural gas, and other fluids. It provides specifications for dimensions, tolerances, mechanical properties, and testing procedures, ensuring consistency and quality throughout the entire production process.

API 5L X52 PSL1: Yield Strength min 360Mpa, Tensile Strength min 460MPa, weld seam of EW, LW, SAW, and cow pipe Tensile Strength min 460MPa;

API 5L X52N/X52Q/X52M PSL2: Yield Strength 360-530Mpa, Tensile Strength 460-760MPa, weld seam of EW, LW, SAW, and cow pipe Tensile Strength min 460MPa.

Determinants of pressure level:

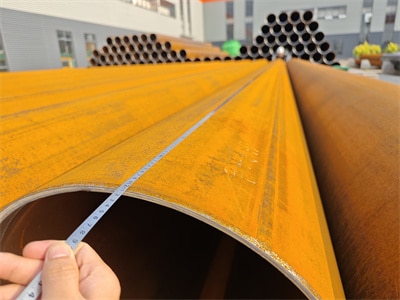

1. Pipeline Size: The pressure rating of API 5L X52 pipeline largely depends on its size, including outer diameter (OD), wall thickness, and length. Thicker walls can withstand higher pressure, while larger diameters can accommodate larger flow rates, but may require higher rated pressure to maintain integrity.

2. Material properties: The mechanical properties of API 5L X52, especially its yield strength, play a crucial role in determining its rated pressure. Higher yield strength means better resistance to deformation and internal pressure, allowing for higher pressure ratings.

3. Operating conditions: The rated pressure of API 5L X52 pipeline is affected by its operating conditions, including temperature, fluid type, and external environmental factors. High temperature and corrosive fluids may require adjustment of pressure ratings to ensure safe operation and service life.

Industry standards and regulations:

The API 5L X52 pipeline must comply with relevant industry standards and regulations for pipeline design, construction, and operation. Standards such as ASME B31.4 (for liquid pipelines) and ASME B31.8 (for gas pipelines) provide guidelines for determining the maximum allowable operating pressure (MAOP) based on factors such as pipeline material, diameter, wall thickness, and operating conditions.

Consultation and verification:

Given the complexity and criticality of pressure ratings, it is crucial to consult experienced engineers, pipeline designers, or manufacturers to accurately determine the pressure ratings for specific applications of API 5L X52 pipelines. Manufacturers typically provide technical data sheets detailing pressure ratings based on standard operating conditions, but customization requirements may require further analysis and validation.

LONGMA produces and stocks API 5L line pipes used for oil and gas transmissions, it includes pipes manufactured in seamless and welded (ERW, SAW). Materials covers API 5L Grade B, X42, X46, X52, X56, X60, X65, X70, X80 PSL1 & PSL2 onshore, offshore and sour services.

- Grades: API 5L Grade B, X42, X52, X56, X60, X65, X70, X80

- Level: PSL1, PSL2, onshore and offshore sour services

- Outer Diameter: 1/2” to 2”, 3”, 4”, 6”, 8”, 10”, 12”, 16 inches, 18 inches, 20 inches, 24 inches up to 72 inches.

- Thickness: SCH 10. SCH 20, SCH 40, SCH STD, SCH 80, SCH XS, to SCH 160

- Manufacturing Types: Seamless, Welded ERW (Electric resistance welded), SAW (Submerged Arc Welded) in LSAW, DSAW

- Length Range: SRL (Single Random Length), DRL (Double Random Length), 20 FT (6 meters), 40FT (12 meters) or, customized Protection Caps in plastic or iron

- Surface Treatment: Natural, Varnished, Black painting, FBE, 3PE (3LPE), 3PP, FBE

Contact by info@ilongma.com to get more information.