- 1. Overview of ASTM A671 Standard and Grade Classification

- 2. ASTM A671 CA, CB, and CC Grade Comparison

- 3. How to Select the Appropriate ASTM A671 Grade Based on Project Environment?

- 4. Reference Cases for ASTM A671 Grade Applications in Real-World Engineering Projects

- 5. Selection Considerations and Procurement Recommendations for ASTM A671 Steel Pipes

With the rapid development of high-demand industries such as petrochemicals, power generation, and energy transmission, the selection of engineering pipeline materials has become a critical factor in ensuring both project safety and cost-effectiveness. As a widely adopted standard for electric-fusion-welded steel pipes used in medium to low temperature environments, ASTM A671 is commonly applied in boilers, heat exchangers, and pressure pipeline systems. Due to its excellent weldability and high strength, different grades under this specification—such as CA grade pipes, CB grade pipes, and CC grade pipes—have demonstrated unique advantages and specific areas of application in real-world projects. However, relying solely on traditional experience to make material choices is no longer sufficient to meet the rigorous requirements of modern projects.

This article presents a practical ASTM A671 selection guide, offering in-depth analysis of applications of different welded steel pipe grades, along with comprehensive A671 pipe material selection suggestions and comparisons of engineering pipe materials. Our goal is to help project engineers identify the most suitable A671 steel pipe grade based on actual environmental and operational conditions, thereby ensuring long-term performance and reliability of the system!

Overview of ASTM A671 Standard and Grade Classification

1. Standard Introduction

ASTM A671 is a standard developed by the American Society for Testing and Materials (ASTM) for electric-fusion-welded carbon steel pipes, primarily intended for pressure service at atmospheric and lower temperatures. It is widely used in industries such as petrochemicals, power plants, and heat exchangers.

2. Applicable Base Materials

Pipes under ASTM A671 are typically manufactured from pressure vessel quality plates conforming to ASTM A or B series specifications, such as ASTM A516 (for low-to-medium temperature service) or ASTM A285 (for general pressure applications). These materials ensure sufficient toughness and strength during both welding and service.

3. Grade Classification System

The ASTM A671 standard includes three main grade categories: CA, CB, and CC. Each grade is further classified by base metal strength levels such as Grade 60, Grade 65, and Grade 70. The distinctions are primarily based on impact test requirements and service conditions:

CA Grade: Impact tested at room temperature, suitable for general applications where moderate toughness is sufficient.

CB Grade: Impact tested at lower temperatures, intended for colder or more variable climates.

CC Grade: Designed for extremely low-temperature or severe service conditions; often used in cryogenic or high-demand environments.

Understanding the applications of different welded steel pipe grades helps ensure more accurate material selection in engineering projects.

4. Testing and Inspection Requirements

Pipes manufactured under ASTM A671 must undergo various levels of mechanical testing, non-destructive weld inspections (such as ultrasonic or radiographic testing), and impact tests, depending on the specified grade. Higher grades require stricter quality control.

5. Importance of Grade Selection

A clear understanding of the ASTM A671 grading system forms the basis for creating a reliable ASTM A671 selection guide. By selecting the right grade, engineers can make informed A671 pipe material selection recommendations that optimize cost, performance, and reliability, while minimizing the risk of material mismatch or failure in critical projects.

ASTM A671 CA, CB, and CC Grade Comparison

ASTM A671 divides welded carbon steel pipes into CA, CB, and CC grades to meet different environmental and performance requirements. Understanding the differences among these grades helps engineers create a reliable ASTM A671 selection guide and make sound A671 pipe material selection recommendations.

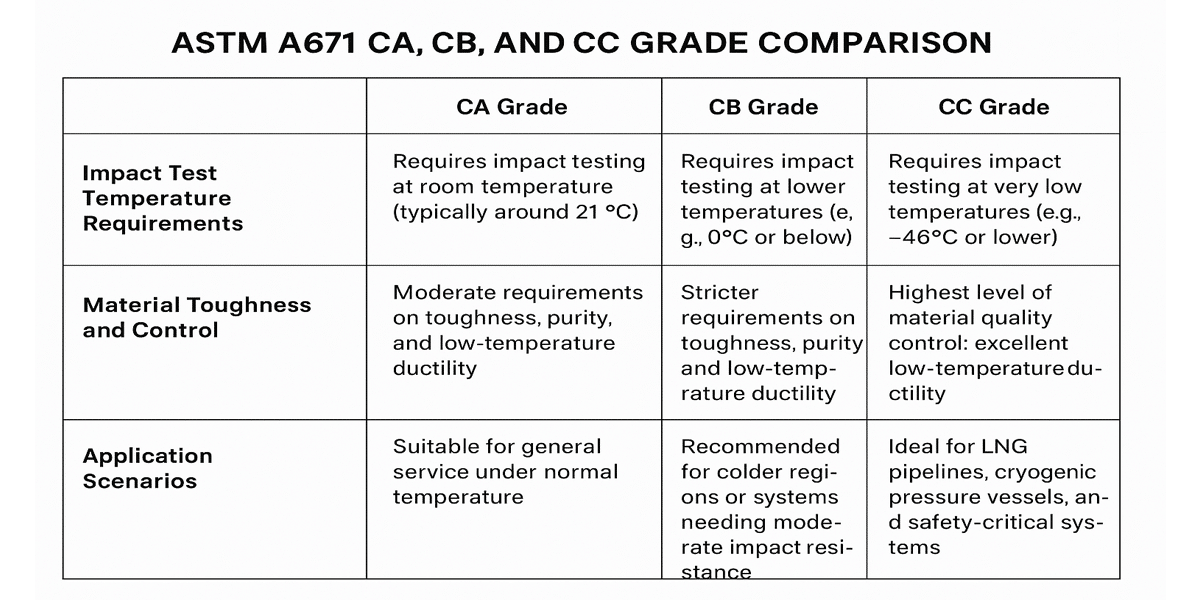

1. Impact Test Temperature Requirements

CA Grade: Requires impact testing at room temperature (typically around 21°C), suitable for applications where moderate toughness is acceptable.

CB Grade: Requires impact testing at lower temperatures (e.g., 0°C or below), intended for colder climates or environments with large temperature fluctuations.

CC Grade: Requires impact testing at very low temperatures (e.g., -46°C or lower), designed for cryogenic service, low-temperature fluid transport, and high-reliability systems.

2. Material Toughness and Control

While all three grades can use the same base plate materials such as ASTM A516 Grade 70, CB and CC grades have stricter requirements on material toughness, purity, and low-temperature ductility. CC grade demands the highest level of material quality control.

3. Application Scenarios

CA Grade: Suitable for general service under normal temperature, such as low-pressure water systems or standard steam pipelines.

CB Grade: Recommended for colder regions or systems needing moderate impact resistance, such as district heating or power plant piping.

CC Grade: Ideal for LNG pipelines, cryogenic pressure vessels, and safety-critical systems requiring reliable performance at sub-zero temperatures.

4. Cost and Selection Advice

As the grade level increases, so do the material cost, testing standards, and fabrication complexity. When selecting A671 steel pipes, it is essential to evaluate service temperature, fluid characteristics, and project risk level, comparing different grade applications to ensure both performance and cost-efficiency.

How to Select the Appropriate ASTM A671 Grade Based on Project Environment?

Choosing the right ASTM A671 grade (CA, CB, or CC) is essential to ensure the safety, cost-efficiency, and long-term reliability of piping systems. The following selection guide integrates key factors such as temperature, fluid type, risk level, and cost, and naturally incorporates related terms like ASTM A671 selection guide, welded steel pipe applications by grade, engineering pipe material comparison, and A671 pipe material selection advice.

1. Operating Temperature

Ambient temperature (> 0°C)

Use CA grade pipe, which is cost-effective and suitable for general service conditions involving water, steam, or air.

Examples: municipal water supply, HVAC systems, low-pressure steam pipelines.

Cold climates (0°C to -20°C)

CB grade pipe is recommended for environments with moderate cold temperatures and occasional temperature fluctuation.

Examples: heating systems in northern power plants or cold regions such as Russia or Canada.

Extreme cold or cryogenic service (≤ -46°C)

CC grade pipe must be used in cryogenic or high-reliability systems due to its excellent low-temperature ductility and fracture resistance.

Examples: LNG pipelines, cryogenic storage, and high-risk pressure systems.

2. Type of Medium

Ordinary fluids or gases: For water, air, or low-pressure steam, CA grade is sufficient.

Combustible, cold, or high-pressure media: For natural gas or condensates, CB or CC grade is recommended.

LNG, refrigerants, or other cryogenic media: Only CC grade is appropriate.

3. Project Risk Level

Low-risk projects: Such as municipal pipelines or auxiliary factory systems, can use CA grade.

Medium-risk projects: Like industrial pipelines or power generation systems, CB grade offers better reliability.

High-risk projects: Such as petrochemical plants or extreme temperature/pressure environments, require CC grade.

4. Cost vs. Manufacturability

Each grade of welded steel pipe varies significantly in terms of cost and inspection requirements:

5. Integrate Codes, Experience, and Field Conditions

For a sound A671 pipe material selection recommendation, it’s best to combine the ASTM A671 selection guide with actual site conditions, design life, service fluid characteristics, and construction constraints. This ensures optimized selection based on performance, safety, and economic feasibility.

Reference Cases for ASTM A671 Grade Applications in Real-World Engineering Projects

In practical engineering, ASTM A671 welded steel pipes of different grades (CA, CB, CC) are widely used across critical sectors such as energy, chemical processing, power generation, and offshore facilities. The following case studies illustrate how different grades are selected based on specific project environments, serving as a useful reference for A671 pipe material selection recommendations and ASTM A671 selection guide in various applications.

1. LNG (Liquefied Natural Gas) Pipeline Project – Recommended: CC Grade

LNG systems operate at extremely low temperatures, often down to -162°C. Pipe materials must provide excellent low-temperature impact toughness and fracture resistance.

Selection Rationale: CC grade pipes are tested at cryogenic conditions, ensuring reliability in LNG applications.

Case Example: An LNG terminal export line near a coastal region used ASTM A671 Gr.CC70 Class 22 pipes, designed for -46°C. The system has been operating reliably for over 5 years.

2. Medium-Pressure Natural Gas Transmission Pipeline – Recommended: CB Grade

Transmission lines for natural gas must withstand sub-zero winter temperatures while maintaining adequate toughness.

Selection Rationale: CB grade provides good low-temperature ductility at moderate cost, making it ideal for gas transmission.

Case Example: A provincial natural gas trunk line used ASTM A671 CB60 Class 12, designed for -10°C and 4.0 MPa pressure. The pipeline has shown stable performance.

3. Power Plant Boiler Feedwater System – Recommended: CA Grade

Feedwater pipelines in power plants typically operate at ambient or slightly elevated temperatures, with limited low-temp requirements.

Selection Rationale: CA grade offers sufficient performance under room-temperature impact tests and is cost-effective for low- to medium-pressure systems.

Case Example: A thermal power station in Central China used ASTM A671 CA65 Class 11 pipes (DN400) in its feedwater circuit, operating between 60–80°C.

4. Offshore Platform Interconnecting Pipelines – Recommended: CC Grade

Pipelines on offshore platforms face extreme temperature fluctuations, salt corrosion, and structural vibration.

Selection Rationale: CC grade pipes offer superior crack resistance and welding stability, suitable for harsh marine environments.

Case Example: A South China Sea offshore facility used ASTM A671 Gr.CC70 pipes to connect the platform to a subsea processing system, ensuring long-term operational safety.

Selection Considerations and Procurement Recommendations for ASTM A671 Steel Pipes

This section provides practical guidance for selecting and purchasing ASTM A671 welded steel pipes, particularly useful for procurement engineers, design teams, and project managers. It incorporates key terms such as ASTM A671 selection guide, A671 pipe material selection advice, engineering pipe comparison, and applications of different grade welded pipes.

I. Selection Considerations

1. Define Project Operating Conditions Thoroughly

Before selecting ASTM A671 pipes, collect accurate operational parameters, including:

Operating temperature range (ambient, low-temperature, or cryogenic)

Medium type (liquid, gas, corrosive, flammable, etc.)

Pressure level (low, medium, or high-pressure systems)

Design life span and expected maintenance cycles

2. Select the Appropriate Grade (CA, CB, or CC)

CA Grade: For ambient temperature and general-purpose fluids

CB Grade: For mild low-temperature service and natural/industrial gas

CC Grade: For cryogenic or safety-critical applications requiring enhanced reliability

3. Assess Welding Compatibility and On-Site Construction

Welding performance varies by grade. Confirm that contractors possess suitable welding procedures and qualifications for the selected material.

4. Ensure Compliance with Project Design Standards

While ASTM A671 is a general standard for welded steel pipes, specific projects may also reference ASME, API, or ISO standards. Ensure full compatibility where necessary.

5. Match Impact Test Conditions to Design Requirements

Especially in low-temperature applications, verify that the impact test temperature and specimen orientation (longitudinal or transverse) align with project specifications.

II. Procurement Recommendations

1. Prioritize Qualified Manufacturers

Select suppliers with proven capabilities to produce ASTM A671 pipes across all grades, along with complete Material Test Certificates (MTC) and traceability documentation.

2. Provide a Detailed Technical Data Sheet (TDS) Before Ordering

Include the following:

Pipe grade and class

Outer diameter, wall thickness, and dimensional tolerances

Required impact test temperature and direction

Heat treatment condition (e.g., normalized, normalized + tempered)

3. Request Third-Party Inspection and Acceptance Testing

For critical projects, engage certified inspection agencies for:

Chemical composition analysis

Impact toughness verification

Ultrasonic/NDT testing

Dimensional and surface quality checks

4. Pay Attention to Transport and Storage Requirements

CB and CC grades are more sensitive to surface damage and corrosion. Use protective coatings and mechanical safeguards during handling and shipping.

5. Consider Staged Procurement Based on Construction Timeline

To reduce storage costs and manage logistics, split purchases across project phases and coordinate deliveries with on-site construction schedules.

In today’s increasingly demanding engineering scenarios, selecting the appropriate grade of ASTM A671 welded steel pipe plays a critical role in ensuring system safety, cost-efficiency, and long-term reliability. This article has provided a structured overview of grade characteristics, application comparisons, and selection strategies—offering a practical ASTM A671 selection guide to help engineering teams avoid overdesign and reduce material mismatch risks. Looking ahead, as global infrastructure expands into harsher environments and diversified energy sectors, the application of welded steel pipes will continue to evolve toward more refined and project-specific standards. Design engineers and procurement professionals are encouraged to collaborate closely, leveraging both field experience and A671 pipe material selection advice to create optimized, economical, and dependable piping solutions that support safe and efficient project execution!