In refinery and natural gas transmission projects, material selection directly determines the system’s safety, operational reliability, and lifecycle cost.

With over 20 years of manufacturing experience, LONGMA has successfully supplied astm a691 alloy steel pipes to numerous large-scale projects, proving their exceptional performance in high-temperature, high-pressure, and corrosive service environments.

This article analyzes real-world applications, technical comparisons, inspection methods, and procurement control measures to help engineers and buyers make informed decisions — while reinforcing LONGMA’s credibility as a trusted supplier.

Typical Engineering Case Overview

Case 1: Refinery Heater and Reheater Steam Lines

- Operating conditions:Continuous service at 550–620°C, high steam pressure, and oxidation/corrosion risks.

- Material selection:astm a691 grade 2.1 4cr (2.25Cr–1Mo) for high creep strength and good weldability.

- LONGMA deliverables:Full MTC package, PWHT curves, WPS/PQR documents, and 100% ultrasonic inspection records.

Case 2: Natural Gas Booster and Transmission Pipeline (Municipal–Plant Interface)

- Operating conditions:Medium to high pressure, trace H₂S and moisture content, risk of sulfide stress cracking (SSC).

- Material selection:astm a691 pipe grades (P1/P9) selected per temperature and pressure design, with full HIC/SSC testing.

- LONGMA deliverables:100% PMI verification, NACE TM0177-compliant HIC/SSC test reports, and third-party inspection by SGS/TÜV.

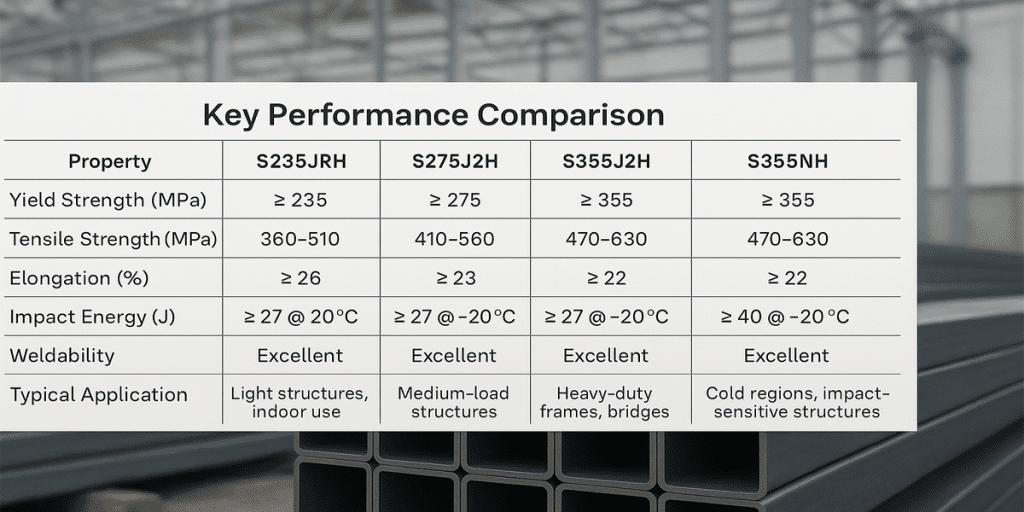

Material Comparison Table

| Parameter / Application | Carbon Steel (e.g., ASTM A106) | Alloy Steel (ASTM A691) |

| Max. Operating Temp. | ≤425°C | ≥600°C |

| Creep Resistance | Moderate | Excellent (2.25Cr–1Mo) |

| H₂S / SSC Resistance | Limited | High (depending on alloy grade) |

| Lifecycle Cost | Low initial cost, high maintenance | Higher cost, longer service life |

| Field Welding Control | Basic | Requires strict WPS, preheat & PWHT management |

Critical Inspection Methods — Purpose, Procedures & Standards

To ensure quality and minimize shutdown or claim risks, all inspection and acceptance criteria should be clearly defined in the technical contract (T/C).

| Test Item | Purpose | Execution | Reference Standard |

| Chemical Analysis (OES) | Verify material composition and prevent mix-ups | Sampling per heat → OES analysis → MTC issued | ASTM A691 / ASTM A20 |

| Mechanical Properties (Tensile / Yield) | Confirm strength and ductility | Tested per ASTM A370 (room & elevated temp) | ASTM A370 |

| Impact Test (CVN) | Assess weld zone toughness | Charpy V-notch at 0°C or –20°C | ASTM A370 Appendix |

| NDT (UT/RT) | Detect internal or weld defects | 100% UT or partial RT as per class | ASTM A691 §7.3 / ASME Sec. V |

| PMI & HIC/SSC Tests | Ensure correct alloy and H₂S resistance | 100% PMI + NACE TM0177 HIC/SSC evaluation | ASTM E1476 / NACE TM0177 |

| PWHT Curve Verification | Confirm compliance of furnace records | Record time-temperature data vs. ASTM A691 Table 2 | ASTM A691 Table 2 |

LONGMA’s Capability: Minimizing Buyer Risk

LONGMA’s in-house laboratory provides a complete quality assurance system covering every stage from raw material to post-production testing:

- Facilities:Optical Emission Spectrometer (OES), universal tensile tester, impact tester, automatic UT/RT lines, portable PMI devices, and fully data-recorded PWHT furnaces.

- Traceability:Each astm a691 pipe is laser-marked with heat number, batch, PWHT record, and inspection code for third-party verification.

- Global Experience:Exported astm a691 pipes & tubes in spain, the Middle East, and Southeast Asia — with all material documentation meeting EN/DIN/NACE project standards.

- Engineering Support:Provides WPS/PQR qualification, heat input monitoring, and complete PWHT curves to support clients in writing T/C clauses and performing site inspections.

Key Procurement & Specification Recommendations

- Define all technical parameters in the T/C, including grade (e.g., astm a691 grade 2.1 4cr), chemical/mechanical limits, PWHT requirements (reference ASTM A691 Table 2), and NDT coverage.

- Insert acceptance clausesrequiring MTCs, PWHT records, WPS/PQR, NDT & PMI reports, and third-party witness rights.

- Prioritize suppliers with internal testing facilitiesand export experience — such as LONGMA — to reduce inspection delays and ensure compliance with international project documentation standards.

Summary: Proven Reliability in Global Projects

The success of ASTM A691 steel pipes in refinery and natural gas transmission systems demonstrates their unmatched combination of strength, oxidation resistance, and long-term stability under extreme conditions.

By integrating advanced laboratory testing, automatic EFW manufacturing lines, and full documentation traceability, LONGMA has become a trusted supplier for global EPC and refinery projects.

From astm a691 grade 2.1 4cr gr 32 in refinery heater systems to astm a691 pipes & tubes in spain gas transmission networks, LONGMA ensures every product meets ASTM, ASME, and NACE requirements — delivering safety, reliability, and confidence with every shipment.