- 1. Introduction to EN 10219

- 2. Dimensional and Tolerance Analysis for Round Tubes under EN 10219

- 3. General Specification Range (Round Tubes)

- 4. Dimensional Tolerance Standards for Round Tubes (as per EN 10219-2)

- 5. Why Are Dimensional Tolerances So Important?

- 6. How Do We Ensure Dimensional Control and Tolerance Compliance?

- 7. Strict Raw Material Standards

- 8. High-Precision Welding Equipment (ERW and LSAW)

- 9. Real-Time Dimensional Monitoring System

- 10. Full Factory Inspection Procedures

- 11. Dimensional Tolerance Control as an Export Advantage

- 12. Conclusion

EN 10219 Steel Pipe Tolerances and Dimensional Standards Explained

In the field of steel pipe manufacturing, EN 10219 serves as a precise benchmark that governs the quality of cold-formed welded structural steel tubes. As a professional manufacturer of circular tubes according to EN 10219, we have a deep understanding of this standard and strictly adhere to it—especially in terms of dimensional tolerance control. We have invested significant technical resources to ensure that we deliver high-quality products that meet international standards.

Introduction to EN 10219

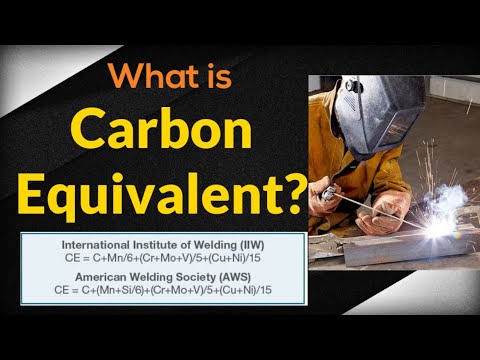

EN 10219 is a European technical standard for cold-formed welded structural steel tubes (hollow sections), divided into two parts:

- EN 10219-1: Technical delivery conditions covering chemical composition, mechanical properties, impact toughness, etc.

- EN 10219-2: Dimensions, tolerances, and sectional properties, clearly specifying the size standards and permissible deviation ranges for various cross-sectional shapes.

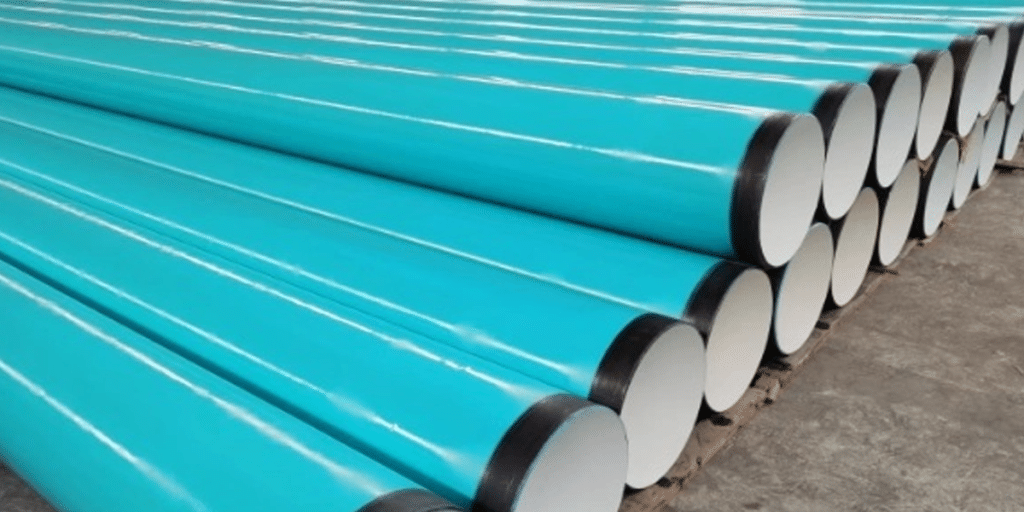

This standard applies to welded steel tubes in various structural forms. Our factory specializes in producing and supplying round tubes—specifically, Electric Resistance Welded (ERW) and Longitudinal Submerged Arc Welded (LSAW) types. Our products are widely used in construction, bridge building, wind power, mechanical supports, and other sectors.

Dimensional and Tolerance Analysis for Round Tubes under EN 10219

General Specification Range (Round Tubes)

- Outside Diameter Range: 21.3 mm to 508 mm

- Wall Thickness Range: 1.5 mm to 20 mm (customizable)

- Length Range: 6 m, 12 m, or fixed length; negative deviation or fixed length + cutting tolerance is acceptable

Dimensional Tolerance Standards for Round Tubes (as per EN 10219-2)

| Product Dimension | Permissible Tolerance for Round Tube |

| Outside Diameter | ±1% (minimum ±0.5 mm) |

| Wall Thickness | ±10% (minimum ±0.2 mm) |

| Ovality | Max 2% of outside diameter |

| Straightness | Max 2 mm per meter or 0.2% of total length |

| Length Tolerance | Fixed length ±50 mm; adjustable by agreement |

Note: Upon customer request, stricter tolerances can be implemented, such as ±0.5% for outer diameter and ±5% for wall thickness.

Why Are Dimensional Tolerances So Important?

Accurate dimensional control plays a crucial role in the structural stability, safety, and efficiency of steel pipe applications:

- Ensures Structural Integrity: Smaller deviations allow tighter fits and stronger overall structures.

- Improves Weld Quality: Greater roundness and accurate alignment lead to more stable welds with reduced residual stress.

- Facilitates Automated Assembly: Especially in projects like wind turbine towers and bridge supports, dimensional accuracy directly impacts assembly efficiency.

- Enhances Post-Processing: Stable diameters and roundness support uniform galvanizing and coating distribution.

How Do We Ensure Dimensional Control and Tolerance Compliance?

As a professional manufacturer of round ERW and LSAW tubes per EN 10219, we have implemented a complete and scientific quality control system from raw material sourcing to final inspection:

Strict Raw Material Standards

We maintain long-term partnerships with top-tier domestic steel mills (such as Baosteel, Angang, Shagang, etc.) to ensure that the hot-rolled coils and steel strips meet EN 10219 requirements and possess good rolling uniformity—laying a strong foundation for consistent welding and forming.

High-Precision Welding Equipment (ERW and LSAW)

- ERW Production Line: Utilizes high-frequency induction welding and forming technology to precisely control outer diameter and weld seam position.

- LSAW Production Line: Uses double-sided submerged arc welding and fully automated edge milling for accurate seam alignment.

- Forming Process: Maintains deviation within ±0.5%, meeting high-precision project requirements.

Real-Time Dimensional Monitoring System

We have adopted a range of real-time monitoring tools on our production lines:

- Laser Diameter Gauge: Precisely controls outer diameter, with error-alarm system adjusting forming pressure automatically.

- Ultrasonic Wall Thickness Gauge: Dynamically checks wall thickness consistency—especially suitable for thick-walled structural pipes.

- Automated Ovality Detection System: Scans pipe roundness in real time to ensure circularity of finished tubes.

- 3-Meter Straightness Platform: Verifies the full-length straightness of steel pipes.

Full Factory Inspection Procedures

Each product batch must go through the following quality assurance steps:

- First-piece size measurement

- ≥10% in-process sampling inspection

- Final dimensional inspection with report issuance

- EN 10204 3.1 Material Certificate (MTC)

- Third-party inspection (SGS, BV, etc.) available for export compliance

Dimensional Tolerance Control as an Export Advantage

Over the years, our EN 10219 round tubes have been steadily exported to countries such as:

- European Union, United Kingdom, Singapore, Australia, New Zealand, Peru, and more

- Widely used in wind power structures, foundation supports, tunnels, mechanical equipment frameworks, and other infrastructure projects

- Clients consistently praise our products for their stable sizing, minimal ovality, and smooth weld seams, meeting quality levels of leading international brands

Conclusion

EN 10219 imposes stringent dimensional tolerance requirements. As a professional round pipe manufacturer, we not only continuously upgrade our equipment and processes but also embed the principle of “prevention + monitoring + correction + verification” into our quality control workflow. This ensures that every steel tube we produce meets both standard specifications and the highest customer expectations.

If you’re looking for ERW or LSAW round pipes that comply with EN 10219, we welcome your inquiries and cooperation to jointly deliver high-quality structural engineering solutions!