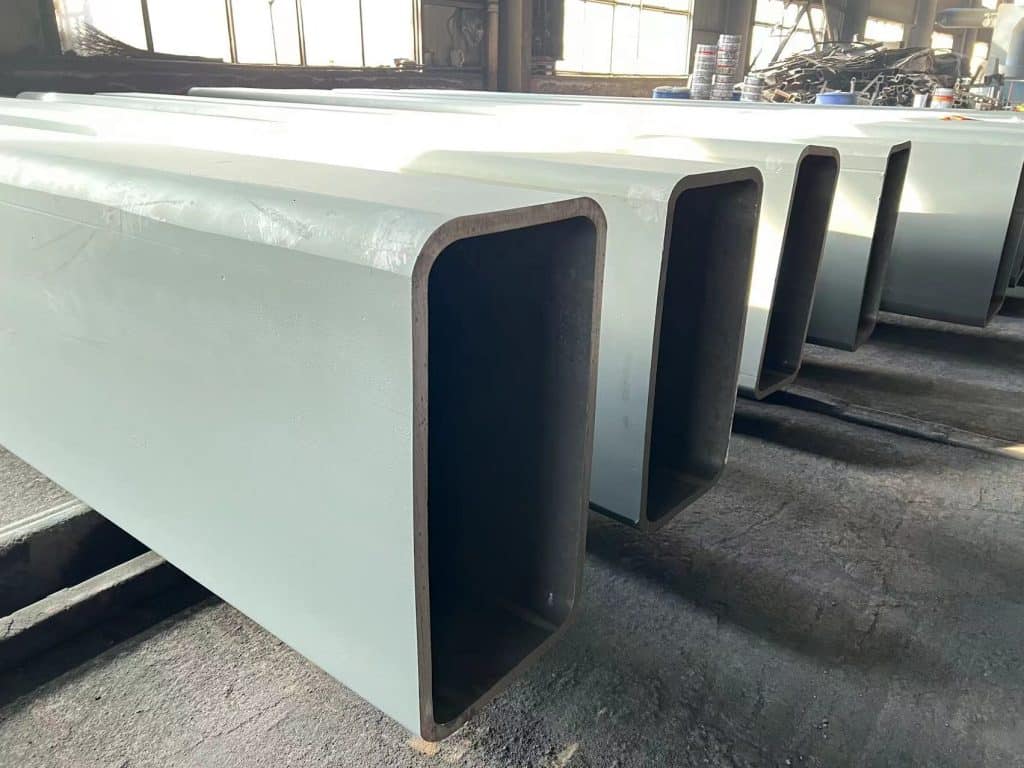

How to cut the AS1163 steel pipes?

AS1163 standard steel pipe can be cut in many ways, and the specific cutting method will depend on the working environment, equipment availability and required precision.

Here are some common cutting methods:

1. Hand saw: suitable for small or simple cutting tasks.

Use manual saws to ensure that saw blades suitable for cutting steel pipes are selected to improve efficiency and cutting quality.

2. Mechanical cutting: the use of mechanical cutting equipment, such as metal cutting machines, circular saws or band saws, can improve production efficiency, especially for a large number of cutting tasks. Ensure that the equipment tools are sharp enough to achieve accurate cutting.

3. Flame cutting: for thicker AS1163 steel pipes(20mm+), flame cutting is a common choice.

Use flame cutting equipment to cut steel pipes by spraying oxygen and fuel flames.

This is suitable for pipes with larger diameter and thicker wall.

4. Laser cutting: laser cutting is an advanced choice for cutting tasks that require high precision and complex shapes.

Laser cutting can provide high accuracy and efficiency, but the equipment cost is high.

5. Water jet cutting: Water jet cutting is a technology that uses high-speed water jet to cut materials, which is suitable for all kinds of materials, including steel pipes. It can provide high precision and does not produce heat-affected zone.

Before cutting, be sure to take appropriate safety measures, including wearing protective equipment, ensuring good ventilation in the work area, and operating in accordance with relevant standards and operating procedures.

In addition, the selection of the appropriate cutting method depends on the workload, the precision required, and the type and size of the material.

LONGMA is one of China leading steel pipes manufacturers since 2003, certified by API 5L, ISO9001, ISO14001, FPC. We can help to cut the AS1163 C250/C350 pipes into your length or type. Contact by info@ilongma.com to get more information.