With global investments in energy and infrastructure rebounding, astm a691 alloy steel pipes are experiencing a steady surge in demand due to their superior performance under high-temperature and high-pressure conditions.

As a manufacturer with over 20 years of industry experience, LONGMA not only provides high-quality products such as astm a691 grade 2.1 4cr, but also ensures risk-free procurement through its advanced in-house testing laboratory and traceable quality control system.

This article analyzes the market dynamics, industrial applications, inspection requirements, and procurement strategies of ASTM A691 pipes to help buyers make confident, data-driven decisions.

Market Drivers and Emerging Trends

- Rising Demand from Energy and Petrochemical Projects

The expansion of refinery modernization, power plant retrofitting, and emerging hydrogen and ammonia energy projectsis driving global demand for astm a691 pipe - Infrastructure and Natural Gas Expansion

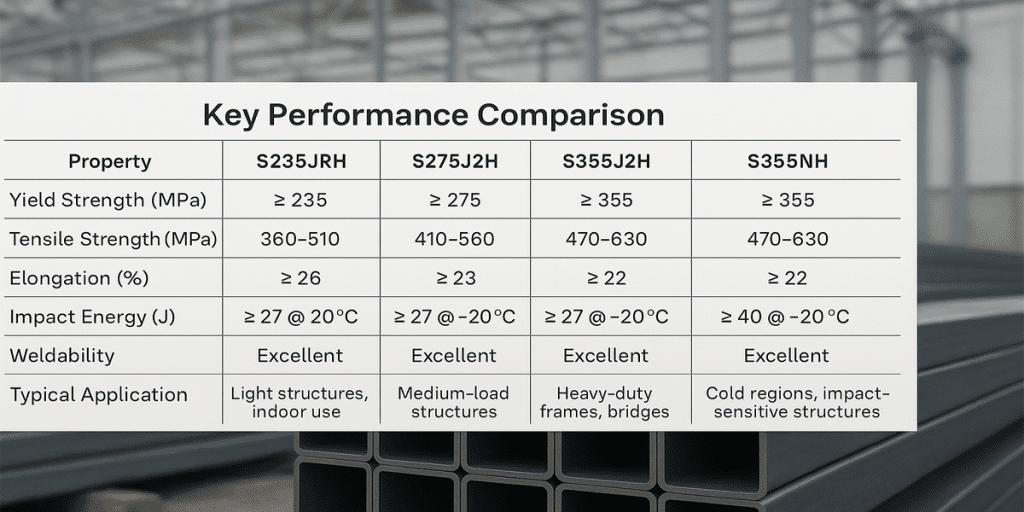

Large-scale pipeline and natural gas transmission projects continue to grow, increasing the need for materials resistant to high pressure, corrosion, and H₂S environments. - Material Upgrade and High-End Substitution

The industry is transitioning from carbon steel to Cr–Mo alloy steelssuch as astm a691 grade 2.1 4cr, providing better long-term strength, oxidation resistance, and weldability — perfectly aligned with global refinery and energy requirements.

Market research indicates that the alloy steel pipe segment will maintain stable growth in the coming years as energy transition and infrastructure investment accelerate.

Demand-Side Industry Distribution

| Industry | Main Driver | Typical Application |

| Refining / Petrochemical | High temperature, high pressure, oxidation resistance | Furnace coils, reheater steam lines using astm a691 grade 2.1 4cr |

| Power / Boiler Systems | Long-term creep resistance at elevated temperatures | Superheater and reheater tubes |

| Natural Gas Transmission | High pressure, H₂S resistance, long-distance networks | Compressor inlet & distribution pipelines |

| Industrial Process Piping | Corrosive fluid transportation | Preferred choice: astm a691 pipe and similar Cr–Mo alloys |

Supply Chain and Market Outlook

- Production Capacity & Lead Time

Global capacity is concentrated among a few major mills. Delivery schedules may fluctuate depending on raw material supply, inspection resources, and regional energy costs.

During infrastructure booms, alloy pipe lead times often extend, highlighting the importance of supplier reliability and laboratory capacity. - Rising Quality and Compliance Requirements

EPC contractors and project owners increasingly require full MTCs, PWHT charts, WPS/PQR documentation, and third-party witnessing.

Suppliers like LONGMA, equipped with in-house testing facilities, can guarantee consistency and reduce reinspection or rejection risks — a key competitive advantage.

Quality Inspection and Acceptance Criteria

To minimize project risk and ensure compliance, the following tests should be explicitly listed in the Technical Contract (T/C):

| Inspection Item | Purpose | Procedure (Example for T/C) | Standard Reference |

| Chemical Composition (OES) | Verify alloy chemistry and prevent mix-up | Test each heat → OES analysis → MTC issued | ASTM A691 / ASTM A20 |

| Mechanical Properties (Tensile) | Verify yield & tensile strength | Batch sampling per ASTM A370 | ASTM A370 |

| Impact Test (CVN) | Assess toughness of weld and HAZ | Conduct Charpy V-notch at 0°C or –20°C | ASTM A370 Appendix |

| NDT (UT/RT) | Detect internal and weld defects | 100% UT or partial RT per class | ASTM A691 §7.3 / ASME Sec. V |

| PMI / HIC / SSC Testing | Confirm alloy and H₂S resistance | 100% PMI; HIC/SSC testing per NACE TM0177 if H₂S present | ASTM E1476 / NACE TM0177 |

| PWHT Record Verification | Ensure post-weld heat treatment accuracy | Provide furnace curve and holding time logs | ASTM A691 Table 2 |

Including these tests in the T/C and granting third-party witness rights (SGS / BV / TÜV) significantly enhances buyer confidence and reduces claim risk.

LONGMA’s Competitive Advantages

- Comprehensive In-House Laboratory

LONGMA operates OES chemical analyzers, tensile and impact testers, fully automated UT/RT inspection lines, and digital PWHT furnaces.

Each product is delivered with a complete MTC + inspection report, ensuring compliance and shortening approval timelines. - Global Export Experience

LONGMA has extensive track records supplying astm a691 pipes & tubes in spain, the Middle East, and Southeast Asia.

The company is well-versed in international documentation, customs clearance, and technical certification requirements. - Engineering and Technical Support

LONGMA provides WPS/PQR qualification, PWHT data, and supports both remote and on-site third-party inspection, offering turnkey solutions for EPC and refinery clients.

Procurement Strategy and Recommendations

- Define all grade and testing requirements in the inquiry or purchase specification — including astm a691 grade 2.1 4cr, NDT levels, and third-party witness clauses.

- For long-term projects, select manufacturers with in-house testing and export experienceto ensure stable lead time and documentation integrity.

- Include sample retesting and penalty clauses to mitigate potential quality or delivery risks.

Conclusion

Overall, the astm a691 alloy steel pipe market will continue its steady expansion, driven by refinery upgrades, power generation projects, and natural gas infrastructure.

The suppliers’ ability to offer technical expertise, quality traceability, and on-time delivery will increasingly determine project success and long-term cooperation.

As a manufacturer with full laboratory capability and global export experience, LONGMA provides high-quality astm a691 pipe products that meet ASTM, ASME, and NACE standards.

Whether for high-pressure refinery systems or astm a691 pipes & tubes in spain, LONGMA ensures every delivery is safe, compliant, and performance-proven — offering buyers both reliability and confidence.