In refinery and petrochemical applications, pipelines are often exposed to high temperature, high pressure, and corrosive media. Selecting the right material directly affects equipment safety, service life, and long-term maintenance costs.

Among various options, ASTM A691 electric-fusion-welded alloy steel pipes stand out for their excellent high-temperature strength, oxidation resistance, and mechanical stability, making them ideal for use in heaters, heat exchangers, and steam pipelines.

Overview of ASTM A691 Standard

| Item | Details |

| Standard Name | ASTM A691 – Standard Specification for Carbon and Alloy Steel Pipe, Electric-Fusion-Welded for High-Pressure Service at High Temperatures |

| Manufacturing Process | Electric Fusion Welded (EFW) from alloy plates, followed by heat treatment |

| Main Applications | High-temperature and high-pressure pipelines, boilers, refineries, petrochemical systems, and heat exchangers |

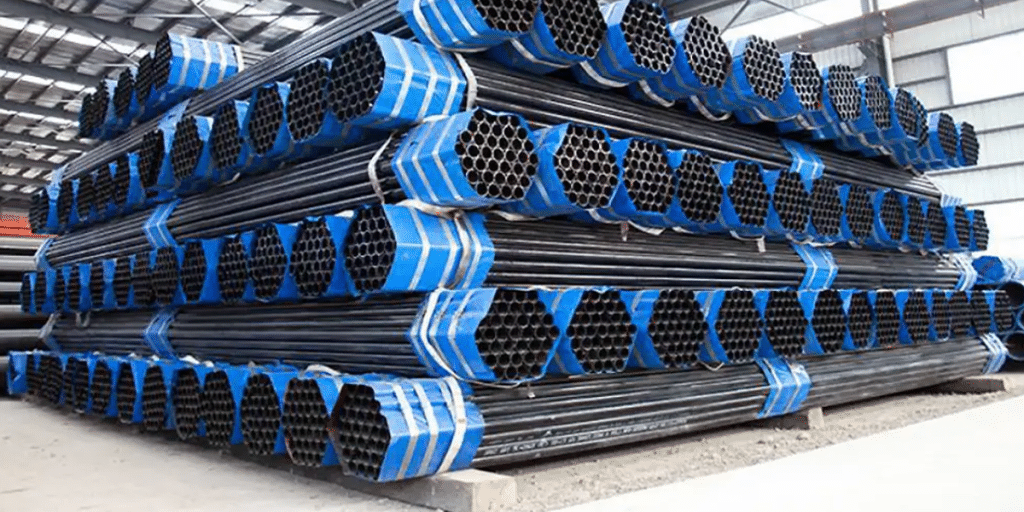

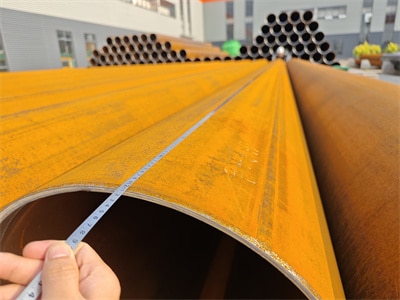

| Size Range | OD: DN50–DN1200; Wall Thickness: SCH40–SCH160 or customized |

| Typical Supply Condition | Normalized & Tempered (N+T) / Quenched & Tempered (Q+T) |

Common Grades and Typical Mechanical Properties

| Grade | Main Chemical Elements (%) | Heat Treatment | Yield Strength (MPa) | Tensile Strength (MPa) | Working Temp. | Typical Application |

| A691 Grade 1.25Cr-0.5Mo | Cr 1.0–1.5 / Mo 0.45–0.65 | N+T | ≥240 | 415–585 | ≤500°C | Medium-temperature reheat or heat recovery systems |

| A691 Grade 2.25Cr-1Mo (also known as astm a691 grade 2.1 4cr or Gr 32) | Cr 2.0–2.5 / Mo 0.9–1.1 | N+T or Q+T | ≥310 | 485–620 | ≤600°C | Steam lines, heater coils, reactor outlet lines |

| A691 Grade 5Cr-0.5Mo | Cr 4.5–5.5 / Mo 0.45–0.65 | N+T | ≥345 | 515–655 | ≤650°C | High-temperature cracking and catalyst regeneration units |

| A691 Grade 9Cr-1Mo | Cr 8–10 / Mo 0.9–1.1 | Q+T | ≥415 | 585–760 | ≤700°C | Ultra-high temperature service, WHR piping |

Note: By adjusting chromium and molybdenum content, different grades of astm a691 pipes achieve enhanced creep resistance and oxidation stability.

Grade 2.25Cr (grade 2.1 4cr) is the most widely used in refinery and petrochemical plants.

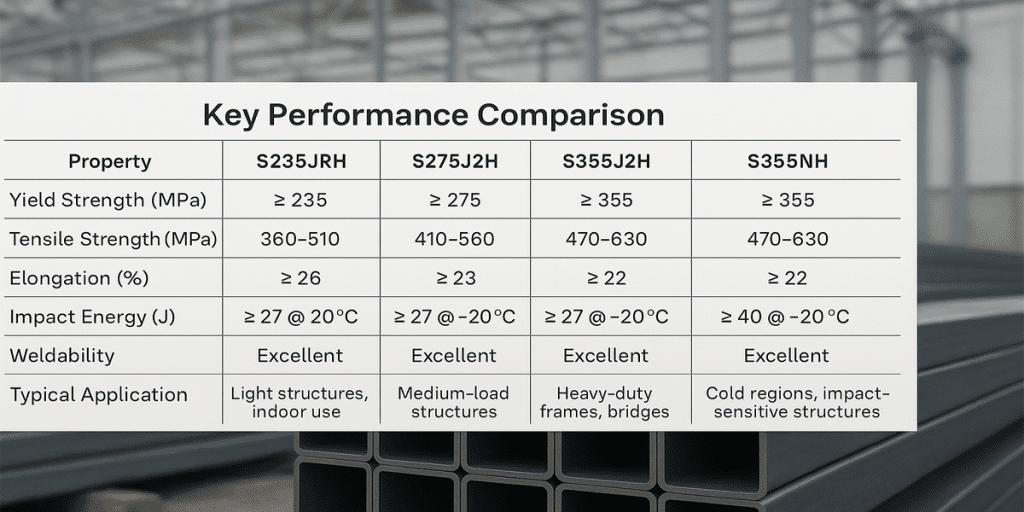

Performance Comparison

| Property | Carbon Steel Pipe (ASTM A106) | Alloy Steel Pipe (ASTM A691) | Advantage |

| High-Temperature Resistance | Up to 425°C | Up to 650°C | Suitable for high-temp steam & hot oil |

| Creep Strength | Poor | Excellent | Less deformation under long-term stress |

| Oxidation & Corrosion Resistance | Moderate | Excellent (due to Cr passive film) | Longer service life |

| Weldability | Good | Good (requires pre/post heat treatment) | Reliable for field welding |

| Economic Value | Low initial cost | Higher initial cost, longer service life | Lower life-cycle cost |

Key Inspection & Quality Control Methods

| Test Item | Purpose | Reference Standard | Method | LONGMA Laboratory Capability |

| Chemical Composition Analysis | Verify alloy chemistry | ASTM A691 + A20 | Optical Emission Spectrometry (OES) | ✔ In-house OES analyzer |

| Tensile & Yield Test | Confirm mechanical strength | ASTM A370 | Universal tensile testing | ✔ High-temp tensile machines available |

| Impact Test (CVN) | Assess toughness at low temp | ASTM A370 (Appendix) | Charpy V-notch | ✔ Up to –20°C testing |

| Non-Destructive Testing (UT/RT) | Detect internal weld flaws | ASTM A691 §7.3 | Ultrasonic / Radiographic | ✔ Fully automatic UT scanning line |

| PMI Material Verification | Avoid material mix-up | ASTM E1476 | Portable spectrometer | ✔ 100% PMI traceable inspection |

| Dimensional & Visual Check | Ensure geometric accuracy | ASTM A530 | OD, WT, Ovality measurement | ✔ Full inspection records |

LONGMA Internal Laboratory conducts all major tests before shipment and issues Mill Test Certificates (MTCs) with third-party verification when required — ensuring product quality and buyer confidence.

LONGMA Brand Strength and Global Reputation

| Key Factor | LONGMA Advantage |

| Industry Experience | Over 20 years of manufacturing expertise for refinery & petrochemical piping systems |

| Production Equipment | Automated EFW welding line, advanced heat treatment furnaces, full NDT system |

| Quality System | Certified by ISO 9001, PED, API; each pipe is fully traceable |

| In-House Laboratory | Equipped for chemical, mechanical, metallographic, and NDT testing |

| Global Export Record | Products exported worldwide, with astm a691 pipes & tubes in spain well recognized for quality |

| Technical Support | Provides material selection advice, welding procedure recommendations, and QA documentation |

Procurement Guidelines and Risk Control

| Step | Recommendation | LONGMA Support |

| Material Selection | Specify grade according to service temperature and pressure (e.g., astm a691 grade 2.1 4cr) | Technical grade selection report |

| Technical Documentation | Require MTC, NDT, Heat Treatment, and PMI reports | Provided for every batch |

| Inspection Process | Add third-party or remote video inspection | Real-time factory inspection supported |

| Long-Term Supply | Establish framework contract for alloy price stability | Annual or project-based agreements available |

Conclusion

ASTM A691 pipes deliver superior strength, stability, and weldability for high-temperature service, making them a trusted choice for refineries and petrochemical plants worldwide.

Partnering with LONGMA, a manufacturer with advanced in-house testing, strict quality management, and proven international experience, ensures reliable quality, full traceability, and on-time project delivery.