What is EN10210-1 S235JR hollow section?

EN 10210-1 S235JR hollow section is a grade of hot-finished structural hollow sections made from non-alloy and fine grain steels, designed to meet specific technical delivery requirements. This grade of steel is particularly valued in construction and engineering due to its mechanical properties and versatility. Below, we explore its applications in various sectors, emphasizing the advantages and considerations for each use.

Applications of S235JR hollow section in Construction

Structural Frameworks

S235JR hollow section is widely used in the construction of structural frameworks for buildings, including commercial, residential, and industrial structures. Its high yield strength (235 MPa) ensures it can support substantial loads, making it ideal for:

– Beams and Columns: Essential for supporting floors and roofs.

– Bracing Systems: Provides stability to the structure by resisting lateral forces.

– Steel Frames: Forms the skeleton of buildings, allowing for large spans and open floor plans.

Bridges

Bridges require materials that can withstand dynamic loads and environmental exposure. S235JRH is used in:

– Bridge Girders: Main load-carrying elements in bridges.

– Pylons and Towers: Supports cable-stayed and suspension bridges.

– Truss Bridges: Forms the interconnected triangular sections that distribute forces efficiently.

Applications in Infrastructure

Pipelines

S235JR hollow section is also utilized in the creation of pipelines due to its robustness and ability to withstand internal and external pressures. Applications include:

– Water Supply Systems: Transporting water over long distances.

– Sewage Systems: Carrying waste water safely and efficiently.

– Gas and Oil Pipelines: Transporting natural gas and oil products.

Support Structures

Support structures for various infrastructure projects often use S235JR hollow section due to its strength and reliability. Examples include:

– Transmission Towers: Supporting electrical power lines.

– Telecommunication Masts: Holding antennas for communication networks.

– Highway Sign Gantries: Supporting road signs and signals.

Applications in Industrial Settings

Manufacturing Equipment

In industrial environments, S235JR hollow section is employed to manufacture equipment that requires both strength and durability, such as:

– Machinery Frames: Providing a stable base for heavy machinery.

– Conveyors: Supporting systems for moving materials in factories.

– Storage Tanks: Constructing tanks for storing liquids and gases.

Scaffolding

Temporary structures like scaffolding also benefit from S235JR hollow section due to its ease of fabrication and high load-bearing capacity. Scaffolding is essential for:

– Construction Sites: Providing access and support for workers and materials.

– Maintenance and Repairs: Facilitating work on existing structures.

Engineering Applications

Support Structures

Engineering projects often use S235JR hollow section for constructing support structures that must endure varying loads and conditions, such as:

– Cranes and Lifting Equipment: Components like booms and frames.

– Transport Infrastructure: Structural elements in ports and railways.

– Industrial Platforms: Supports for equipment and machinery.

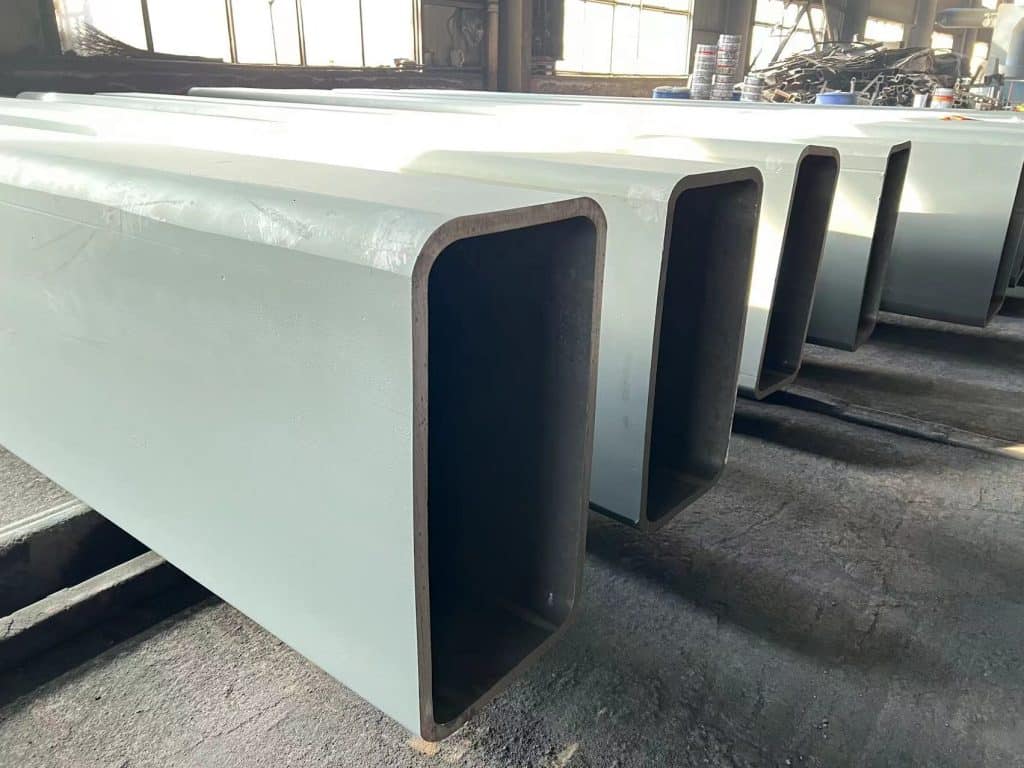

Frames and Machine Components

The steel’s versatility extends to various machine components and frames, where precise mechanical properties are crucial. Applications include:

– Frames for Heavy Equipment: Ensuring stability and durability.

– Press Frames: Withstanding high pressures in industrial presses.

– Robotic Arms: Providing the necessary strength for repetitive tasks.

Environmental and Safety Considerations

Durability and Weather Resistance

S235JR hollow section is designed to withstand various environmental conditions, making it suitable for outdoor applications where exposure to weather is a concern. Its properties ensure:

– Long Service Life: Resistance to corrosion and wear.

– Safety: High structural integrity reduces the risk of failure under load.

Compliance with Standards

The steel meets rigorous European standards, ensuring:

– Consistency in Quality: Adherence to EN 10210-1 specifications guarantees uniformity.

– Safety Regulations: Compliance with construction and engineering safety standards.

Advantages of Using S235JR hollow section

1. High Strength: With a minimum yield strength of 235 MPa, it supports substantial loads.

2. Versatility: Suitable for a wide range of applications in different sectors.

3. Durability: Excellent resistance to environmental factors and mechanical wear.

4. Ease of Fabrication: Can be easily welded and formed into various shapes.

5. Compliance with Standards: Ensures reliability and safety in structural applications.

Reference Standard: EN10210-1 Hot finished structural hollow section of non-alloy and find grain steels

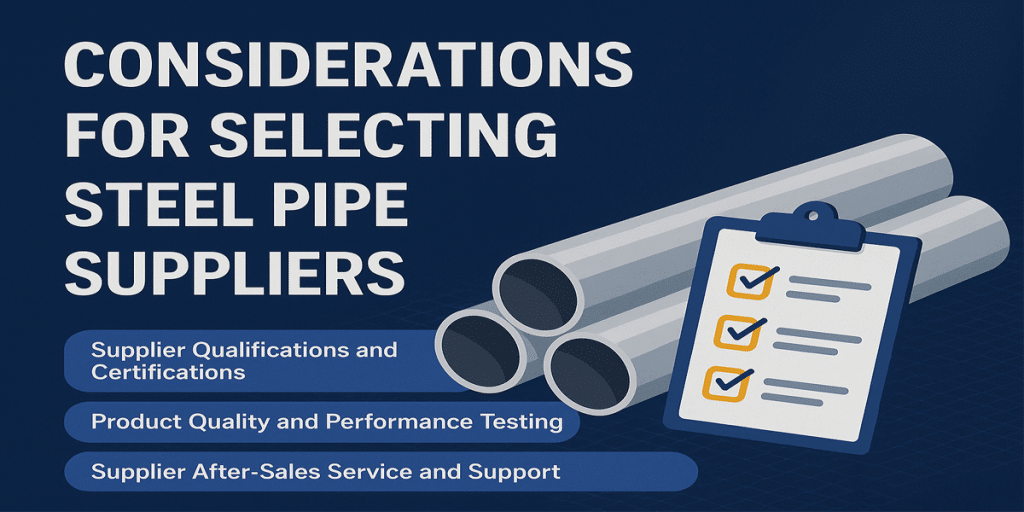

LONGMA produce and export EN10210-1 S235JR hollow section since 2003. As one of China leading steel pipes manufacturers since 2003, certified by API 5L, ISO9001, ISO14001, FPC, LONGMA always supply high quality S235 JR welded steel pipes/S235JR ERW steel pipe with full range pipe grades & pipe specifications. Contact by info@ilongma.com to get more information.