- 1. Chemical Composition and Mechanical Properties of S355J2

- 2. Table 1: Chemical Composition of S355J2 (mass percentage)

- 3. Table 2: Mechanical Properties of S355J2

- 4. Meaning of “S355J2H”

- 5. Main Applications of S355J2H Longitudinal Submerged Arc Welded Steel Pipe

- 6. Common Specifications of EN 10219 S355J2H Steel Pipe

- 7. Countries and regions where S355J2H standard and steel grade are commonly used

- 8. Advantages of choosing LONGMA as the supplier of EN 10219 S355J2H LSAW steel Pipes

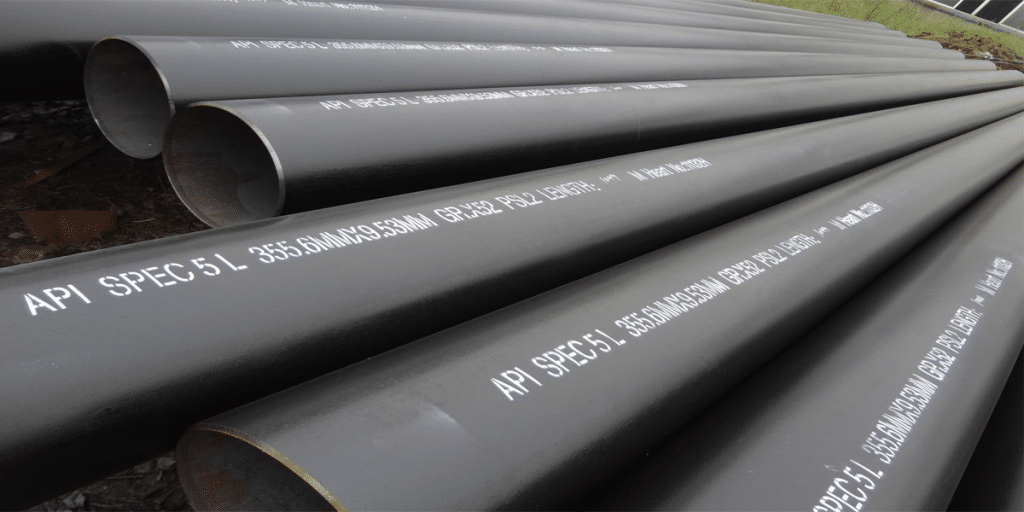

What is EN10219 S355J2 hollow Section (S355J2H LSAW steel pipe)?

EN 10219 is a standard developed by the European Union for cold-formed welded hollow sections for structural use, which is widely applied worldwide. S355J2 is one of the high-strength low-alloy structural steel grades under this standard, featuring excellent toughness, weldability, and impact resistance, making it particularly suitable for structural engineering in low-temperature environments. The following is a detailed explanation of this section from aspects such as standards, performance, and applications.

Chemical Composition and Mechanical Properties of S355J2

According to EN 10219-1 standard, the chemical composition and mechanical properties of S355J2 are as follows:

Table 1: Chemical Composition of S355J2 (mass percentage)

| Element | C (max) | Mn | Si (max) | P (max) | S (max) | N (max) | CU (max) |

| Content | 0.22 | ≤1.60 | 0.55 | 0.030 | 0.030 | 0.012 | 0.55 |

Table 2: Mechanical Properties of S355J2

| Item | Required Value |

| Yield Strength (ReH) | ≥ 355 MPa (wall thickness ≤16mm) |

| Tensile Strength (Rm) | 470–630 MPa |

| Elongation A₅ | ≥ 22% |

| Impact Toughness | ≥ 27J at -20℃ |

Meaning of “S355J2H”

“S355J2H” is the complete grade designation in the EN 10219 standard, with the following meanings:

- S: Structural steel;

- 355: Minimum yield strength is 355 Mpa;

- J2: Indicates that the impact test is conducted at -20℃, and the impact absorption energy is ≥27J, suitable for low-temperature environments;

- H: Represents hollow section, which meets the toughness requirements specified in EN 10210.

Main Applications of S355J2H Longitudinal Submerged Arc Welded Steel Pipe

EN 10219 S355J2H hollow sections are widely used in the following engineering and industrial scenarios:

- Steel structure engineering: Bridges, high-rise buildings, port hoisting structures

- Machinery manufacturing: Heavy machinery frames, crane booms, etc.

- Infrastructure construction: Subways, high-speed railways, tunnel support

- Energy projects: Wind power towers, oil and gas pipeline supports

- Port and marine engineering: Wharf pile foundations, offshore platform structures

Due to its excellent low-temperature toughness and high-strength performance, S355J2H is particularly suitable for engineering projects in cold regions such as Northern Europe, Russia, and Canada.

Common Specifications of EN 10219 S355J2H Steel Pipe

According to EN10219-2 standard, the specification range of S355J2H longitudinal submerged arc welded steel pipe is as follows:

| Item | Range |

| Outer Diameter (OD) | 219mm – 1820mm |

| Wall Thickness (WT) | 6mm – 50mm |

| Length | 6m – 18m, or fixed length |

| Surface Treatment | Black, oiled, anti-corrosion coating |

| Executive Standard | EN 10219-1/2 |

Countries and regions where S355J2H standard and steel grade are commonly used

EN 10219 S355J2H is a mainstream standard in the European market and is widely used in the following countries and regions:

- European region: Germany, France, the United Kingdom, Italy, the Netherlands, etc.

- Nordic countries: Sweden, Norway, Finland, often used in cold-resistant projects

- Eastern Europe and Russia: Applied in energy and heavy industry projects

- Middle East and North Africa: Used in infrastructure and port engineering

- Asian region: India, South Korea, and Japan are gradually introducing this standard

Advantages of choosing LONGMA as the supplier of EN 10219 S355J2H LSAW steel Pipes

Hebei LONGMA is a leading manufacturer of ERW and LSAW round pipes in China, specializing in the research, development, and manufacturing of EN 10219 series structural steel pipes. The advantages of choosing LONGMA include:

- Standardized production: Strictly controlled in accordance with EN 10219 and EN 10204 certification systems.

- Strong production capacity: With an annual output of over several hundred thousand tons, it can quickly meet large-volume orders at home and abroad.

- Technical support: Equipped with advanced LSAW welding equipment and non-destructive testing (UT/MT) systems.

- High cost performance: Direct supply to European, American, Middle Eastern, and Southeast Asian markets, with rich export experience and competitive prices.

- Customized services: Can provide personalized processing such as fixed length, marking, coating, and lining according to customer needs.

- Full-process services: Support third-party inspection, loading supervision, and one-stop logistics and customs declaration services.

EN 10219 S355J2H hollow section (S355J2H longitudinal submerged arc welded steel pipe) occupies an important position in global structural engineering and industrial manufacturing due to its high strength, good toughness, and excellent weldability. For projects requiring large-diameter, thick-walled, and high-standard steel pipes, choosing S355J2H LSAW pipes that comply with EN 10219 standard is a reliable choice. As a professional manufacturer, LONGMA provides one-stop services and is your trustworthy partner. Welcome to contact us.