What is API 5L? -What does API 5L meaning?

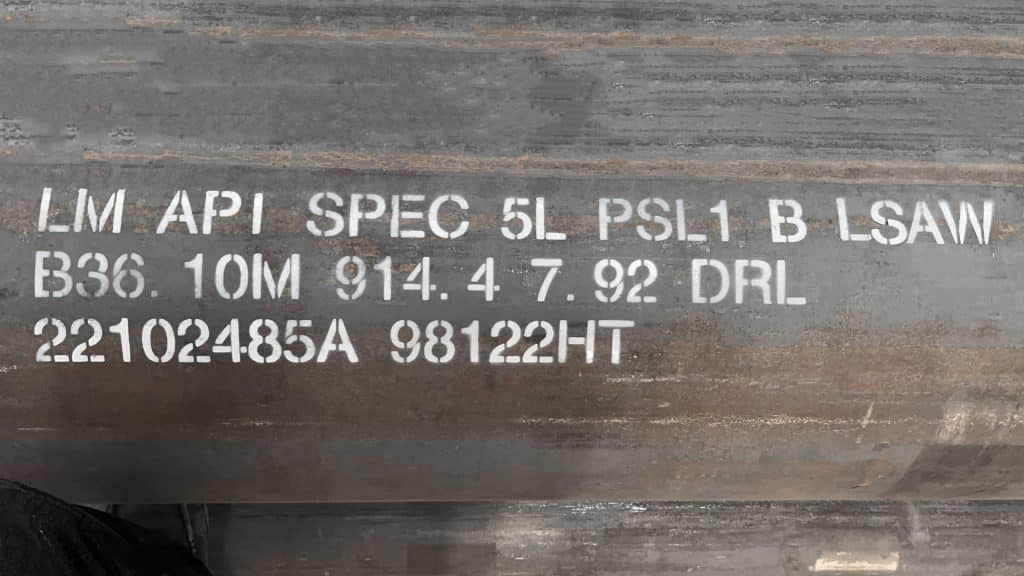

API 5L LINE STEEL PIPES, ERW & LSAW, FOR GAS/OIL/WATER PIPELINE.

API 5L, or American Petroleum Institute Specification 5L, is a widely recognized standard for the manufacture of steel pipe used in the oil and gas industry. The specification is critical to ensuring the integrity and reliability of pipelines used to transport oil, gas and other hydrocarbons.

The primary purpose of API 5L is to establish guidelines for the production of steel pipe with specific properties suitable for a variety of applications within the industry. These applications include the construction of long-distance pipelines across land and sea to facilitate the safe and efficient transportation of petroleum products.

API 5L COVERS DIFFERENT GRADES OF STEEL PIPES

Grade:

API 5L covers different grades of steel pipe, each of which is assigned a specific grade, such as API 5L Grade B, X42, X46, X52, X56, X60, X65, X70, X80, and others. These grades are defined by their mechanical properties, chemical composition and performance characteristics. The choice of grade depends on factors such as the type of hydrocarbon being transported, operating conditions and environmental considerations.

1. API 5L Grade B:

– Application: Suitable for general purpose pipelines in the oil and gas industry.

– Mechanical Properties: Minimum yield strength ≥ 245 MPa (35,500 psi) and minimum tensile strength ≥ 415 MPa (60,200 psi).

2. API 5L X42:

– Application: Used for transportation of low and medium pressure natural gas and oil and gas pipelines.

– Mechanical Properties: Minimum yield strength ≥ 290 MPa (42,100 psi), minimum tensile strength ≥ 415 MPa (60,200 psi).

3. API 5L X52:

– Application: Suitable for natural gas and oil and gas pipelines carrying medium pressure.

– Mechanical Properties: Minimum yield strength ≥360 MPa (52,200 psi), minimum tensile strength ≥460 MPa (66,700 psi).

4. API 5L X60:

– Applications: Used for transportation of high pressure natural gas and oil and gas pipelines.

– Mechanical Properties: Minimum yield strength ≥415MPa (60,200 psi), minimum tensile strength ≥520MPa (75,400 psi).

5. API 5L X65:

– Applications: For high strength, high pressure natural gas and oil and gas pipelines.

– Mechanical Properties: Minimum yield strength ≥ 450 MPa (65,300 psi), minimum tensile strength ≥ 535 MPa (77,600 psi).

6. API 5L X70:

– Application: For high strength, large diameter natural gas and oil and gas pipelines.

– Mechanical Properties: Minimum yield strength ≥ 485 MPa (70,300 psi) and minimum tensile strength ≥ 570 MPa (82,700 psi).

API 5L LINE PIPES INCLUDING TWO LEVES: PSL1 VS PSL2

PSL1 & PSL2

There are two different product specification levels defined in the API 5L standard, namely PSL1 (Product Specification Level 1) and PSL2 (Product Specification Level 2). These two levels have some differences mainly in the manufacturing, chemical composition, mechanical properties, testing and inspection of pipeline steel pipe.

The following are the main differences between API 5L PSL1 and PSL2:

1. Chemical composition:

– PSL1: PSL1 requires a more simplified chemical composition to ensure basic weldability and usability.

– PSL2: PSL2 has more stringent chemical composition requirements and can have higher requirements to improve pipeline properties such as low temperature toughness and corrosion resistance.

2. Mechanical properties:

– PSL1: PSL1 has relatively low requirements for mechanical properties and focuses on basic strength.

– PSL2: PSL2 has higher requirements for mechanical properties, including higher yield strength, tensile strength, impact toughness and hardness indicators.

3. Non-destructive testing:

– PSL1: PSL1 requires non-destructive testing to be limited to eddy current testing.

– PSL2: PSL2 requires more non-destructive testing methods such as ultrasonic testing, magnetic particle testing, X-ray testing, etc. to ensure a higher level of quality control.

4. Impact test:

– PSL1: PSL1 requires impact testing to be performed only at ambient temperature.

– PSL2: PSL2 requires impact testing to be performed at lower temperatures to ensure better low temperature toughness.

5. Welding:

– PSL1: PSL1 pipelines typically have simpler welding requirements.

– PSL2: PSL2 has more stringent welding requirements, including welding process control and weld testing.

The specification also outlines manufacturing processes, inspection procedures and testing requirements to ensure the quality and durability of the pipe. Seamless and welded methods of fabrication are permitted under API 5L, allowing flexibility to meet different project requirements.

API 5L addresses the conditions of use, taking into account factors such as temperature, pressure and environmental factors that the pipe may encounter during its service life. It sets stringent safety and performance standards that provide the foundation for developing pipelines that can withstand the challenges of the oil and gas transportation industry.

In short, API 5L plays a vital role in standardizing steel pipe production and improving pipeline reliability and safety, which is essential for the efficient distribution of hydrocarbons globally.

What is API 5L? Do you understand now?

LONGMA is one of China leading API 5L steel pipes manuacturer since 2003, certified by API 5L, ISO9001, ISO14001, FPC. Contact us by info@ilongma.com to check more about our products API 5L.