- 1. What is ASTM A53 Steel Pipe?

- 2. Core Influencing Factors of ASTM A53 Steel Pipe Prices in 2025

- 3. Raw Material Prices (Hot-Rolled Coil, Steel Billet)

- 4. Energy Costs (Electricity and Natural Gas)

- 5. International Trade and Policy Factors

- 6. Transportation and Logistics

- 7. Market Demand (Industry Prosperity)

- 8. Differences in Production Processes (ERW vs. LSAW)

- 9. Price Trend Forecast for 2025

- 10. Practical Suggestions for Buyers

- 11. Why Choose LONGMA?

The price of ASTM A53 steel pipes in 2025 will be mainly affected by the combined effects of raw material (steel price), energy cost, international trade policies, transportation and logistics, changes in market demand, and differences in production processes (ERW vs. LSAW). Before formulating budgets or signing long-term contracts, buyers need to fully understand these factors to lock in the appropriate procurement timing and supply channels.

What is ASTM A53 Steel Pipe?

ASTM A53 is a standard established by the American Society for Testing and Materials (ASTM), applicable to black/galvanized, seamless, and welded steel pipes (including ERW and LSAW). Its main applications include:

- Water, steam, air, and gas pipelines;

- General mechanical structures;

- Some non-critical structural load-bearing applications.

Core Influencing Factors of ASTM A53 Steel Pipe Prices in 2025

-

Raw Material Prices (Hot-Rolled Coil, Steel Billet)

- Hot-Rolled Coil (HRC) and steel billets are the main raw materials for ERW and LSAW pipes. International iron ore prices, scrap steel supply, and carbon emission policies will all affect raw material prices.

- At the end of 2024, the average price of hot-rolled coils in China and Southeast Asia fluctuated between 560-600 USD/ton, which will remain the price benchmark in 2025.

- Raw materials account for approximately 60%-70% of the total cost of steel pipes, so the trend of raw material prices directly determines the cost of ASTM A53 steel pipes.

-

Energy Costs (Electricity and Natural Gas)

- Electricity, natural gas, and coke are important energy sources for welded pipe production.

- Tight energy supplies in Europe and changes in natural gas import costs in Asia will affect the costs of heating, welding, heat treatment, and galvanizing processes for steel pipes.

- Rising energy prices usually push up the ex-factory price of steel pipes by 5%-10%.

-

International Trade and Policy Factors

- Tariffs and trade barriers: For example, U.S. anti-dumping and countervailing duties on Chinese steel products; import protection policies for steel pipes in Southeast Asia.

- Environmental protection and carbon emission requirements: Carbon taxes and green tariffs (such as the EU’s Carbon Border Adjustment Mechanism – CBAM) may increase additional costs for exports to Europe and the United States.

- Currency exchange rates: A stronger U.S. dollar will reduce export competitiveness, while the depreciation of currencies such as the RMB and Japanese Yen may lower export prices.

-

Transportation and Logistics

- Sea freight is a non-negligible cost in cross-border procurement.

- The Red Sea shipping crisis and the drought in the Panama Canal in 2024 pushed up global shipping costs, and uncertainties are expected to remain in 2025.

- Steel pipes have large volume and high weight, so freight accounts for 5%-15% of the total cost, which has a significant impact especially on long-distance export orders.

-

Market Demand (Industry Prosperity)

- Construction and infrastructure:The U.S. Infrastructure Investment and Jobs Act and urban construction projects in Southeast Asia will drive demand.

- Oil and gas industry:The recovery of energy investment will increase the demand for steel pipes used in pipelines.

- Manufacturing and mechanical processing:Demand is relatively stable, but it is affected by the global economic growth rate.

Global demand for steel pipes is expected to grow moderately in 2025, and prices will remain fluctuating and stable.

-

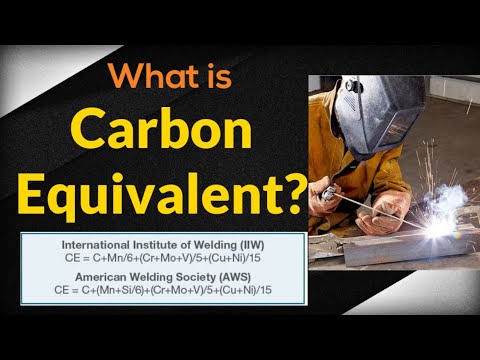

Differences in Production Processes (ERW vs. LSAW)

Different production processes directly affect prices:

| Process | Application Scope | Cost Level | Impact on Price |

| ERW (Electric Resistance Welding) | Small to medium diameters (<24″), conventional pipelines | Low cost | More suitable for price-sensitive projects |

| LSAW (Longitudinal Submerged Arc Welding) | Large diameters (>24″), thick-walled, high-demand projects | High cost | Price is 15%-30% higher than ERW |

Price Trend Forecast for 2025

- Overall trend:Supported by raw materials and energy, the price of ASTM A53 steel pipes will maintain fluctuation at a medium-to-high level in 2025.

- Short-term fluctuations: Affected by international events (wars, energy policies, freight rates), there will be a 5%-10% fluctuation.

- Long-term procurement suggestion:For large-volume orders, it is recommended to sign a price-locked contract with suppliers for more than half a year to avoid fluctuations in raw material and freight costs.

Practical Suggestions for Buyers

- Lock in the trend of raw materials in advance and pay attention to the prices of iron ore and hot-rolled coils.

- Choose reliable suppliers and ensure the availability of Material Test Certificates (MTC) and Non-Destructive Testing (NDT) reports.

- Comprehensively consider the costs of ERW and LSAW, and select the most cost-effective solution according to project requirements.

- Diversify procurement risks and arrange batch delivery or regional procurement reasonably.

Why Choose LONGMA?

As a professional steel pipe manufacturer with more than 20 years of industry experience, LONGMA specializes in the production of ERW and LSAW round pipes and has long-term experience in exporting products that meet standards such as ASTM A53. Our advantages include:

- Strict quality control system: Providing EN 10204 3.1/3.2 MTC to ensure complete records of chemical composition, mechanical properties, and weld treatment;

- Full-process services: Supporting hot-dip galvanizing, cutting, and surface treatment to meet the needs of different projects;

- Rich export experience: Familiar with project standards and acceptance specifications in Europe, America, the Middle East, and Southeast Asia;

- Stable production capacity and inventory: Capable of quickly responding to large-volume orders and ensuring on-time delivery.

If you are planning the procurement of ASTM A53 steel pipes in 2025, please contact us immediately to obtain quotations and selection suggestions. The LONGMA team will provide you with a one-stop solution featuring optimal prices, highest quality, and most reliable delivery.