What does X52 pipe mean?

X52 pipe is a type of API 5L steel pipe that is commonly used in the oil and gas industry. The designation “X52” indicates the pipe’s minimum yield strength, which is 52,000 psi (pounds per square inch). For a more detailed breakdown of what X52 pipe means, please see below:

1. Material Specification:

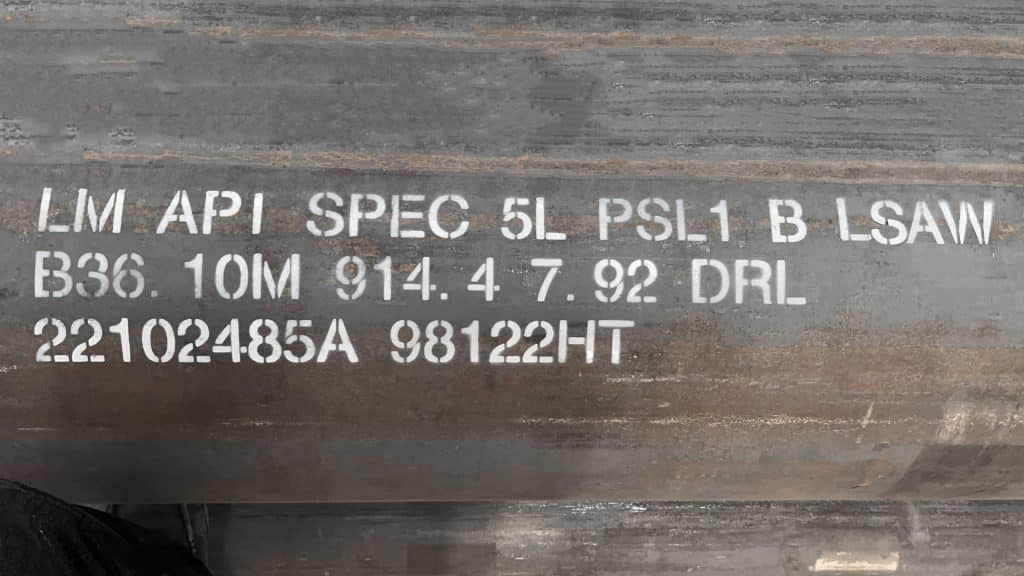

X52 pipe typically adheres to the API 5L standard, which is the American Petroleum Institute’s specification for line pipe used in transportation systems for the oil and natural gas industries. It can be API 5L X52 seamless pipe, API 5L X52 PSL1 LSAW, API 5L X52 PSL2 ERW line pipes, API 5L X52M pipe, API 5L X52Q steel pipes.

2. Grade:

The “X” in X52 signifies that the pipe is a high-strength grade. The number following the “X” indicates the minimum yield strength in thousands of psi. X52 pipe have a minimum yield strength of 52,000 psi.

API 5L X52 pipe PSL1 & PSL2 chemical composition:

| %, t≤25.0mm(0.984in), max | C | Mn | P | S | V+Nb+Ti | Cu | Ni | Cr | Mo | B | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| API 5L PSL1 X52 Seamless pipe | 0.28 | 1.4 | 0.030 | 0.030 | 0.15 | 0.50 | 0.50 | 0.50 | 0.50 | 0.001 | |||||

| API 5L PSL1 X52 Welded pipe | 0.26 | 1.4 | 0.030 | 0.030 | 0.15 | 0.50 | 0.50 | 0.50 | 0.50 | 0.001 | |||||

| %, t≤25.0mm(0.984in), max | C | Si | Mn | P | S | Cu | Ni | Cr | Mo | B | CE(IIW) | V | Nb | Ti | V+Nb+Ti |

| API 5L PSL2 X52N Seamless pipe | 0.24 | 0.45 | 1.4 | 0.025 | 0.015 | 0.50 | 0.30 | 0.30 | 0.15 | 0.004 | 0.43 | 0.10 | 0.05 | 0.04 | 0.15 |

| API 5L PSL2 X52Q Seamless pipe | 0.18 | 0.45 | 1.5 | 0.025 | 0.015 | 0.50 | 0.30 | 0.30 | 0.15 | 0.004 | 0.43 | 0.05 | 0.05 | 0.04 | - |

| API 5L PSL2 X52M Welded pipe | 0.22 | 0.45 | 1.4 | 0.025 | 0.015 | 0.50 | 0.30 | 0.30 | 0.15 | 0.004 | 0.43 | - | - | - | 0.15 |

CE(IIW)=C+Mn/6+(Cr+Mo+V)/5+(Cu+Ni)/15

API 5L X52 Pipe Types

Ranges by Product Specification Level: PSL1, PSL2, Sour Services

API 5L X52 PSL1, for the pipes in common delivery condition of As Rolled.

API 5L X52N/M/Q, for PSL2 pipe with delivery condition of N, M, and Q.

API 5L X52NS/MS/QS, for PSL2 pipes with sour services.

Suffix Letter Means

R: As rolled

N: Normalizing rolled, Normalized formed, Normalized

Q: Tempered and quenched

M: Thermomechanical rolled or thermomechanical formed

S: Sour Service

API 5L X52 pipe PSL1 & PSL2 tensile tests:

| Pipe Grade | Pipe Body of seamless and welded pipes | Weld Seam of EW, LW, SAW and COW ppes | |||

|---|---|---|---|---|---|

| Yield Strength Mpa, min | Tensile Strength Mpa, min | Ratio, max | Elongation % | Tensile Strength Mpa, min | |

| API 5L PSL1 X52 pipe | 360 | 460 | - | * | 460 |

| API 5L PSL2 X52N pipe | 360-530 | 460-760 | 0.93 | * | 460 |

| API 5L PSL2 X52Q pipe | 360-530 | 460-760 | 0.93 | * | 460 |

| API 5L PSL2 X52M pipe | 360-530 | 460-760 | 0.93 | * | 460 |

3. API 5L X52 Pipe Specifications

Standard:API 5L, ISO 3183

Grade: X52 or L390 (N, Q, M, R) in PSL1 and PSL2

Seamless OD: 21.3mm – 660mm, 1/2” – 26”

ERW and HFW pipe: 1/2” – 24”

LSAW and SSAW: 16” – 100”

Wall Thickness Schedule: SCH 40, SCH STD, SCH80, SCH XS, SCH 160, SCH XXS etc

Length: DRL, SRL, 20FT, 40FT

Ends: Plain, Beveled Ends, Threaded Ends

Available Coating: Black Painting, Varnished, FBE, 3PE, 3LPE, 3PP, CRA clad and lined pipe

4. Applications:

X52 pipe are used in various applications, including the transportation of oil, gas, and water. They are often used in pipelines, flowlines, and other infrastructure projects due to their strength and durability. X52 pipe has specific chemical and mechanical properties that make it suitable for high-pressure applications. The chemical composition typically includes carbon, manganese, and other elements that enhance its mechanical properties.

5. X52 Seamless vs. Welded:

X52 pipe can be manufactured as either seamless or welded. Seamless pipes are made without a weld seam, providing higher pressure ratings and better uniformity in mechanical properties. Welded pipes are manufactured by welding the edges of a rolled steel plate or strip together, and they are generally more cost-effective than seamless pipes.

6. X52 pipe Manufacturing Processes:

X52 pipe can be produced using various manufacturing processes, including hot rolling, cold drawing, and others, depending on the specific requirements of the application.

Ranges by Manufacturing Types

X52 Seamless pipe: Includes hot rolled seamless and cold drawn seamless.

X52 ERW pipe: Electric Resistance Welded, OD up to 24 inch.

X52 DSAW/SAW pipe: Double Sub-merged Arck Welding, substitute welding methods than ERW for larger diameter welded pipes.

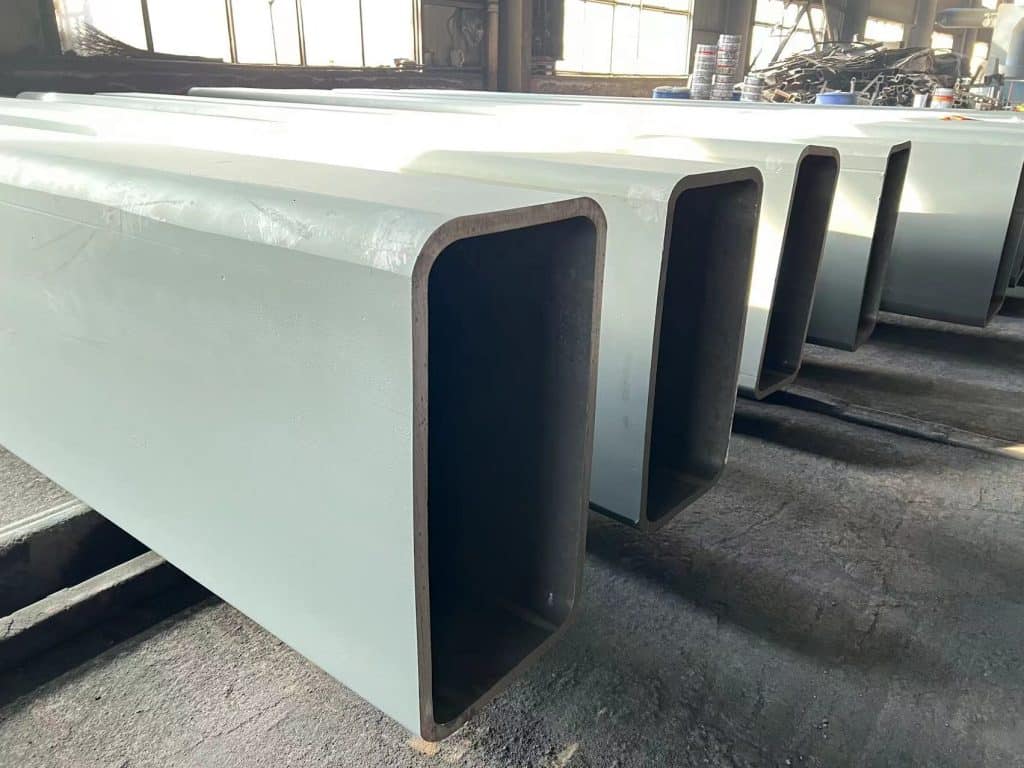

X52 LSAW pipe: Longitudinal Sub-merged Arc Welding, also called JCOE pipe, OD up to 56 inch.

X52 SSAW / HSAW pipe: Spiral Sub-merged Arc Welding, or Helical SAW, OD up to 100 inch.

7. API 5L X52 pipe test Requirements:

Hydrostatic Test: 100% hydrostatic test without leakage through the weld seam or the pipe body required. Connections or joints not need hydrostatic test if the pipe sections used were successfully tested.

Bend Test: No cracks should be occur in any part of the sample or opening of weld.

Flattening test: Flattening test used to prove the pipe performances under deformation. It shall show the resistance to longitudinal cracking and circumferential cracking, including internal and external defects.

It shall be perfored to ERW pipes which diameters above 12.75 inch;

For pipes OD/WT > 10, there shall be no opening of the weld before the distance between the plates is less than 30% of the original OD.

Guided-bend test: Fracture completely; Reveal any cracks or ruptures in the weld metal longer than 3.2 mm, regardless of depth. Or reveal in parent metal, HAZ or fusion line longer than 3.2mm or deeper than 12.5% of wall thickness.

CVN impact test: (Required PSL2 pipe, for seamless shall be tested with pipe body, for welded tests including pipe body, weld seam and heat-affected zon HAZ tests)

DWT test: (Required for PSL2 pipe)

LONGMA, a leading China steel pipes manufacturer since 2003, certified by API 5L, ISO9001, ISO14001, ISO18001, FPC… Contact by info@ilongma.com to get more information.

Our Supply Ranges and Sizes

API SPECS 5L Gr. X52 or L415

Standard: API 5L, ISO 3183

Grade: X52 pipe or L360 pipe (Suffix letter N, Q, M, R)

Welded ERW pipe: 21.3mm – 508mm, 1/2” – 20”

LSAW and SSAW pipe: 406mm – 2500mm, 16” – 100”

Pipe Thickness Schedule: SCH 10, SCH 20, SCH 30, SCH STD, SCH40, SCH60, SCH XS, SCH 80, SCH 100, SCH 120, SCH 140, SCH 160, SCH XXS of the standard thickness

Range of Length: SRL, DRL, 5 meter to 14 meter